Treatment equipment for recycling car washing waste water and automatic control system

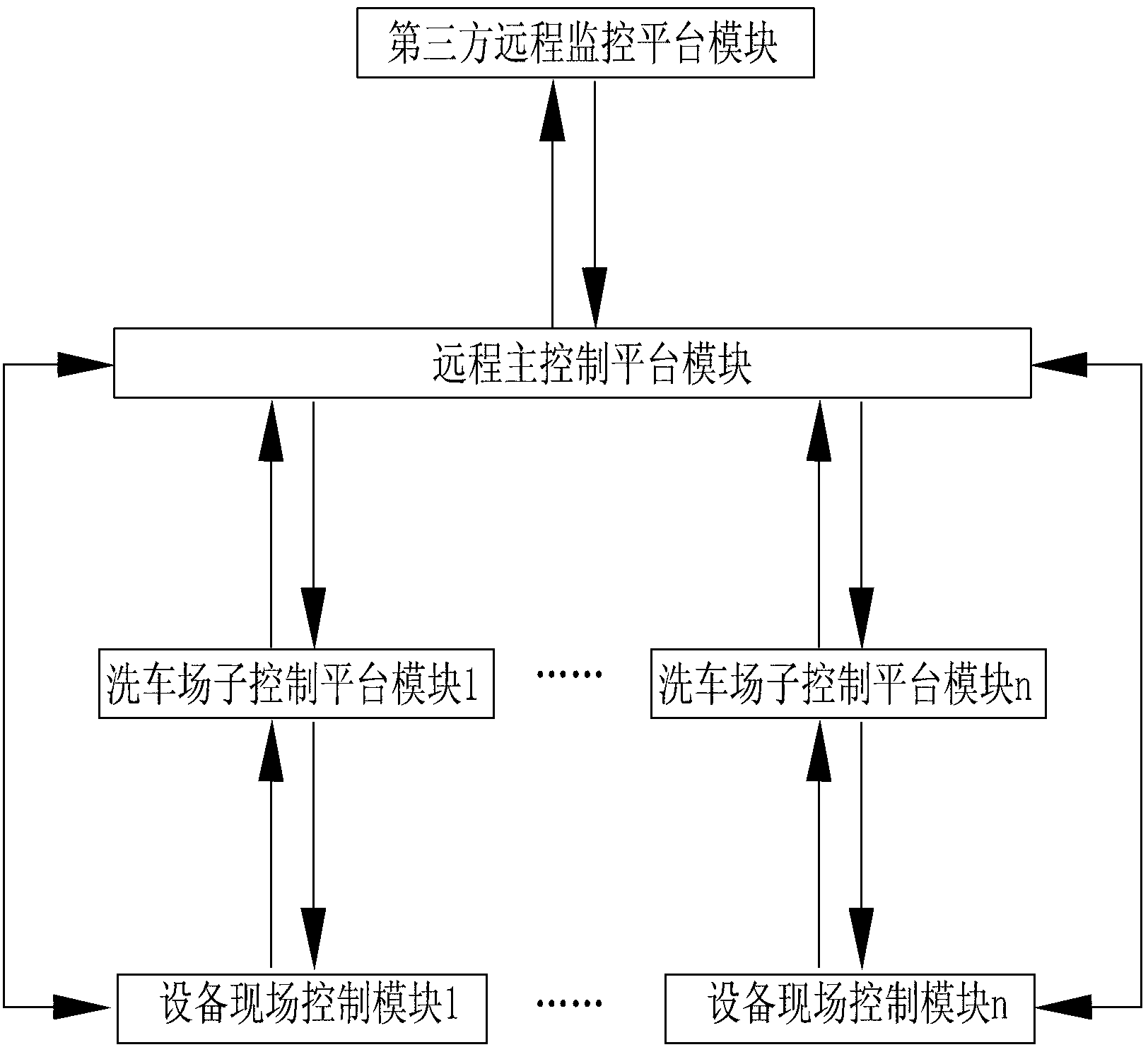

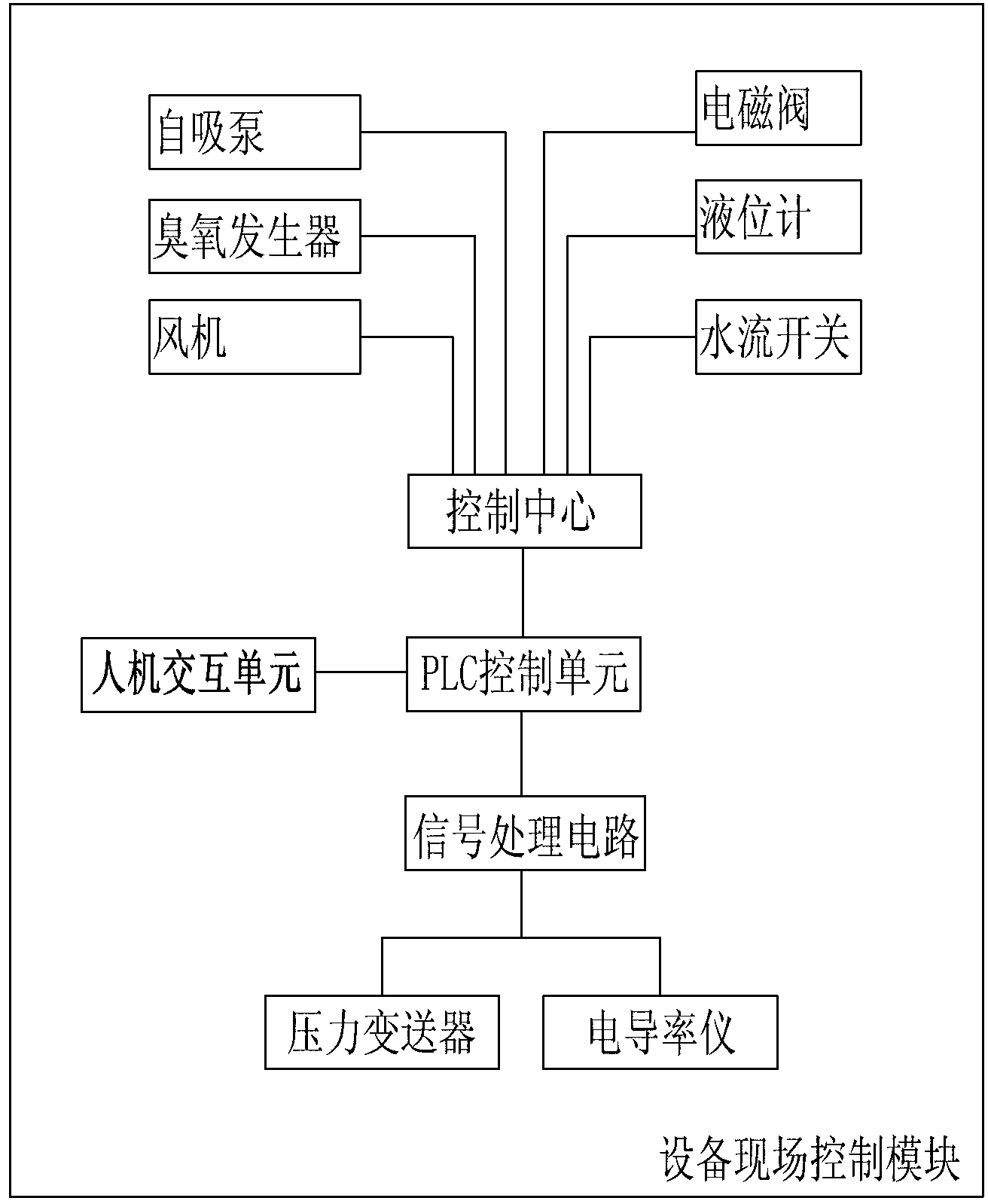

A technology for recycling and car washing wastewater, which is applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, electrical program control, etc. It can solve the problems of poor effluent quality, difficult supervision, and poor applicability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

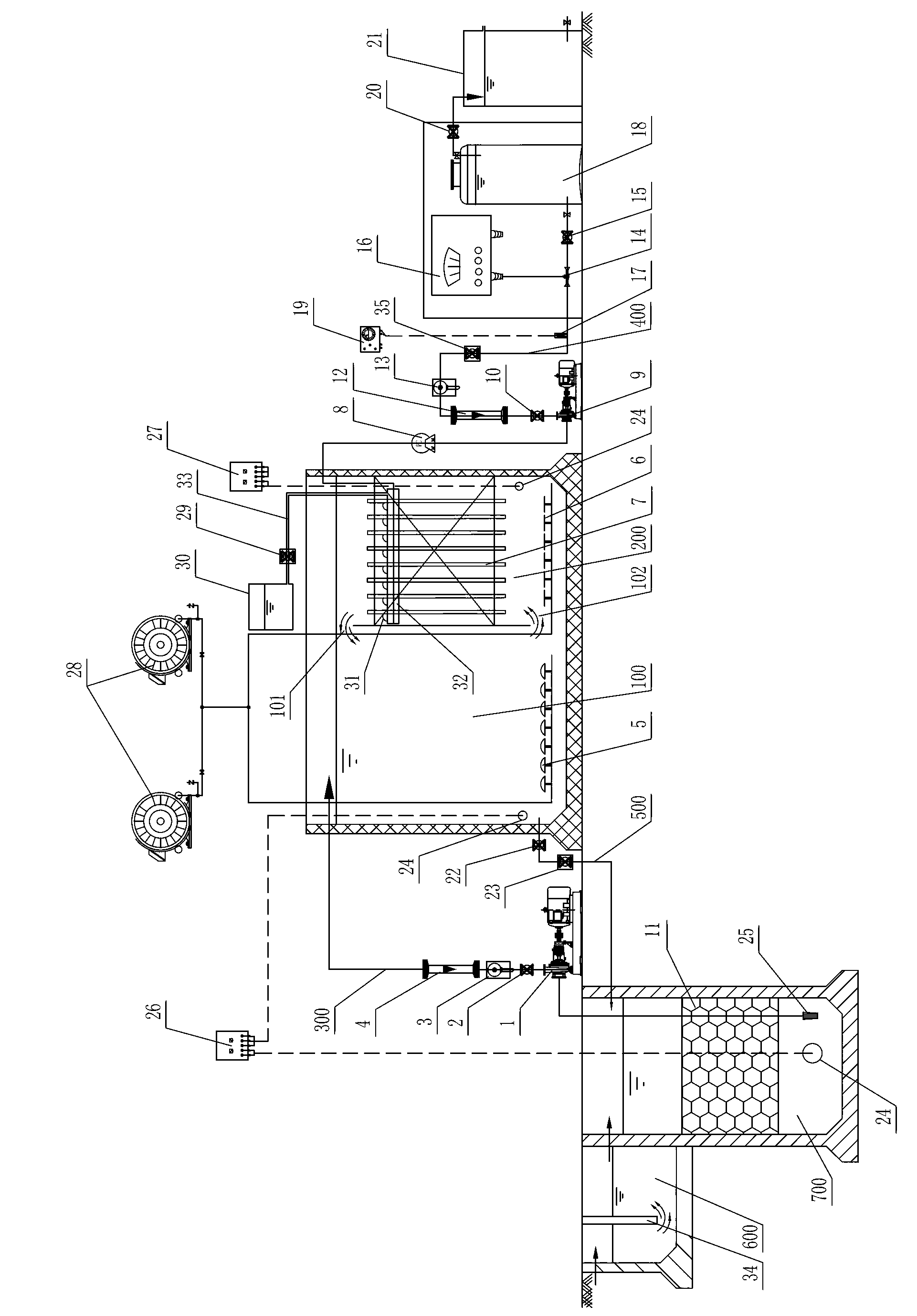

[0025] Such as figure 1 As shown, the car wash wastewater circulation treatment equipment of the present embodiment includes an oil separation grit chamber 600, an anaerobic adjustment tank 700, a biochemical reaction tank 100, a flat MBR tank 200, an ozone generator 16, an ozone mixing disinfection tank 18, and a reuse water tank 800, the oil-separating grit chamber 600 is provided with an oil-separating plate 34, the anaerobic regulating tank 700 is provided with a suspended filler 11, and the biochemical reaction tank 100 and the flat MBR tank 200 are located in the same housing to form Biochemical and flat-panel MBR combination pool, the biochemical reaction pool 100 and the flat-panel MBR pool 200 are connected up and down with circulation channels 101, 102, and the biochemical reaction pool 100 and the flat-panel MBR pool 200 are respectively provided with exposure The air head 5 and the aeration pipe 6 supply oxygen to the aeration head 5 and the aeration pipe 6 through...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

| separation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com