Model bottom plate and sand box transfer device

A technology of transfer device and bottom plate, which is applied in the direction of casting molding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of high manufacturing cost and failure rate of transfer roller table, and relatively high requirements for operation accuracy, so as to improve safety production capacity, Improvement of operational reliability and reduction of manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

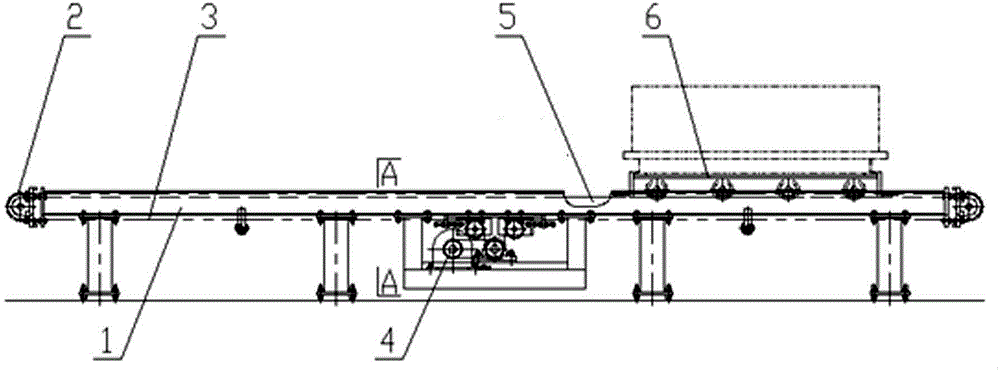

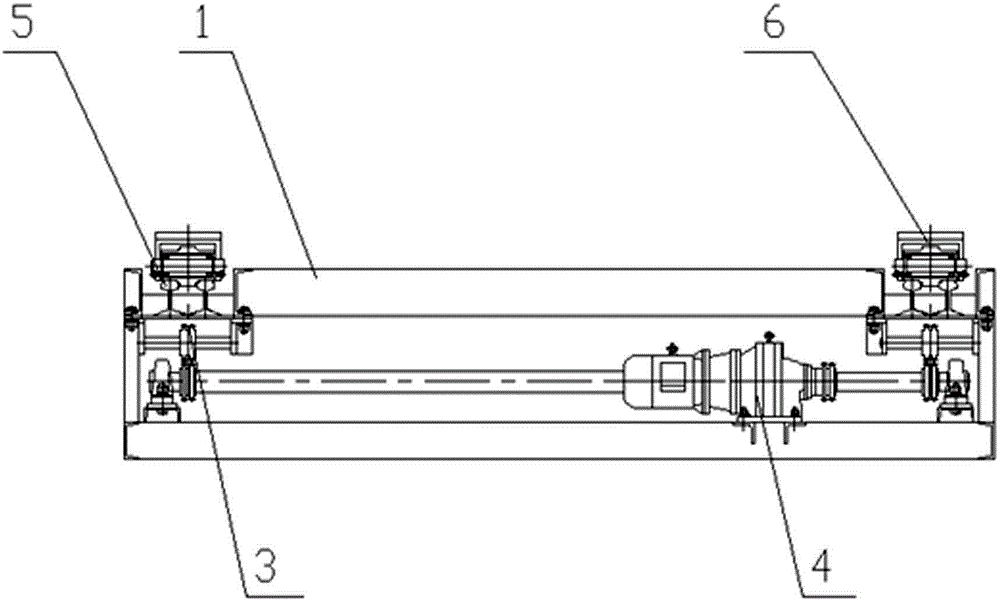

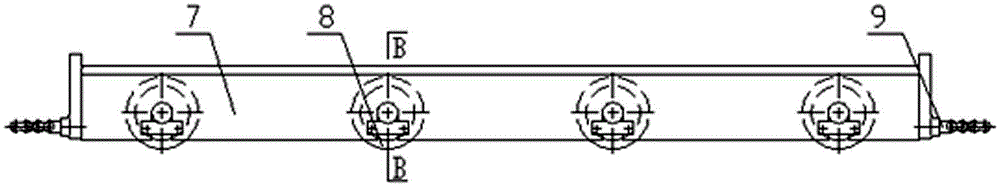

[0012] The specific embodiments of the present invention will be described with reference to the drawings.

[0013] Such as figure 1 , figure 2 The model bottom plate and sand box transfer device includes a frame 1, which is composed of steel structure legs and a steel structure upper frame. A pair of sprockets 2 are respectively provided at both ends of the upper frame body of the frame 1, and a pair of sprockets 2 at each end are installed coaxially. A drag chain 3 is mounted on every two corresponding sprockets 2 front and rear. A drag chain drive mechanism 4 composed of a reduction motor and a sprocket chain drive mechanism is provided under the upper frame of the frame 1 at the middle position. The two sets of drive chain drive mechanisms of the drag chain drive mechanism 4 are respectively corresponding to one Drag the chain 3 to match. Load-bearing rails 5 composed of two parallel steel rails are respectively provided on both sides of the upper part of the frame 1, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com