Compacting table for casting moulding

A vibrating table and molding technology, which is applied in the direction of casting molding equipment, molding machines, manufacturing tools, etc., can solve the problems of vibration of peripheral equipment and buildings, the level of the vibrating table surface, and the impact on the lives of surrounding residents, etc., to achieve surface quality Good, improve the safety production capacity, the effect of high compaction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The specific embodiment of the present invention will be described with reference to the accompanying drawings.

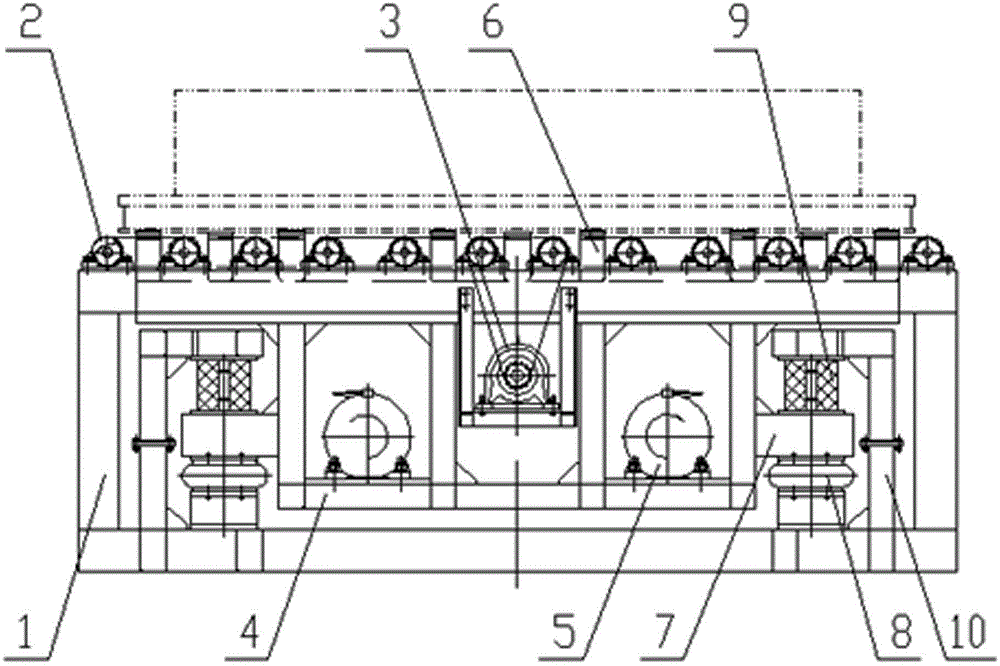

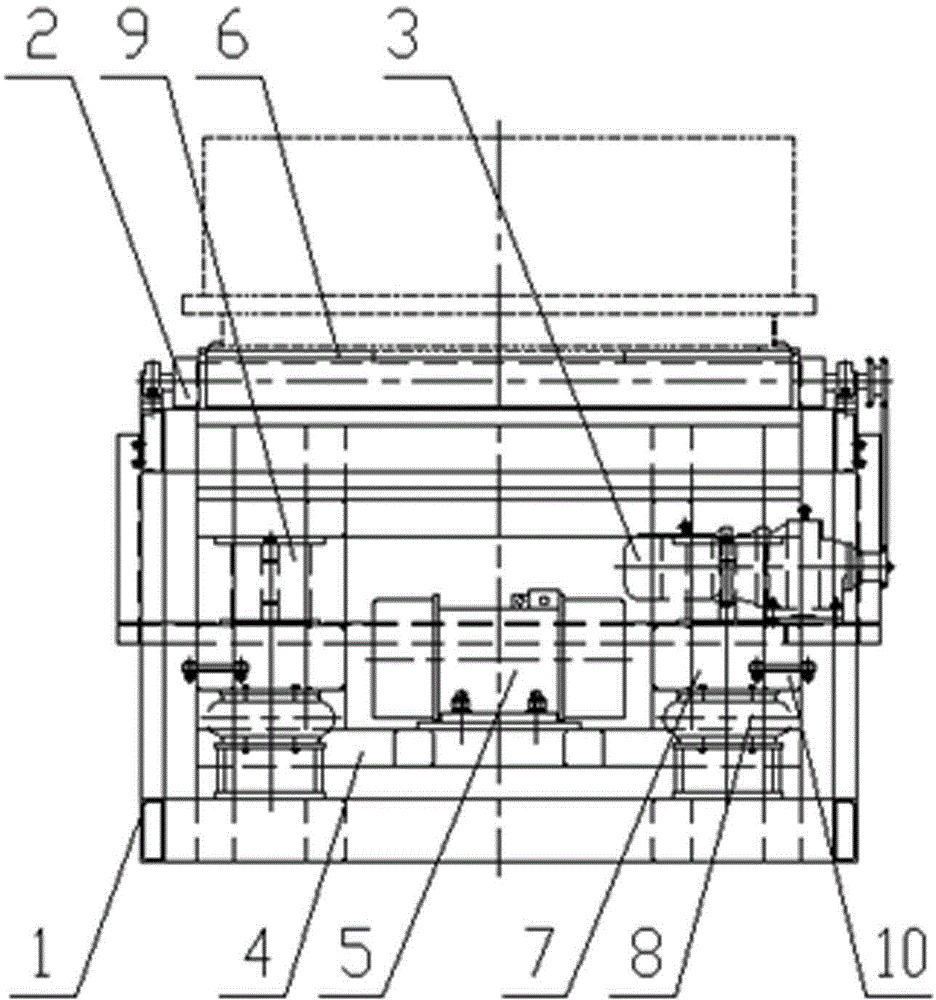

[0014] Such as figure 1 , figure 2 , The vibration table for casting molding includes a roller frame 1, and the roller frame 1 is fixed on the equipment foundation. On the roller table frame 1, idler rollers 2 are arranged transversely, and each idler roller 2 is installed on the surface of the roller table frame 1 through a bearing with a seat. The idler driving mechanism 3 is composed of a reduction motor and a sprocket chain transmission mechanism arranged on the roller frame 1 . A vibrating frame 4 is arranged inside the roller table frame 1, and the vibrating frame 4 is a rectangular frame structure. Vibration motor 5 is arranged at the bottom of vibrating frame 4, as the accompanying drawing embodiment, vibration motor 5 is arranged symmetrically a pair of left and right. The upper end of the vibrating frame 4 is provided with a joist 6 arranged t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com