Method for completely unloading mineral aggregates from skip

A skip and mineral material technology, applied in the field of mine hoist control, to avoid major accidents, improve safety production capacity, and avoid overload or severe overload operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

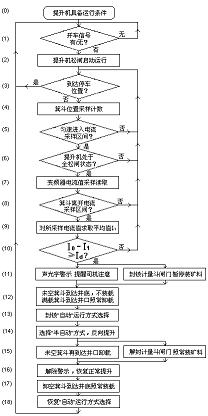

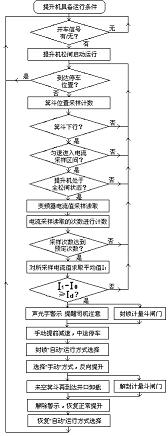

[0034] Embodiment of the present invention is described in conjunction with accompanying drawing:

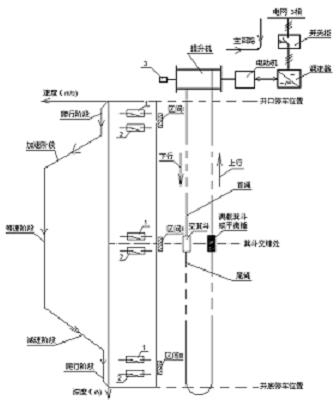

[0035] A method to ensure that the skip unloads the mineral material. A fixed interval is set; when the hoist is in the state of full release, when the unloaded skip enters this interval at a uniform speed, the current of the main circuit is continuously controlled in a cyclic manner. Sampling and reading; judge whether the unloaded skip is empty by comparing the measured value with the reference value. If the unloaded skip is not empty, take corresponding measures to ensure that the unloaded skip is empty.

[0036] The fixed interval is established by setting a position detection device in the space where the skip has been discharged at a constant speed, and the position detection device is a position detection element; the skip that has been completely unloaded is hoisted in the set interval. The current value of the main loop is used as a reference value and stored in the mai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com