Patents

Literature

54 results about "Length weight" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Flushable wipe and method of forming the same

ActiveUS20150330029A1Without losing its functional strength propertiesNatural cellulose pulp/paperMechanical working/deformationEngineeringLength weight

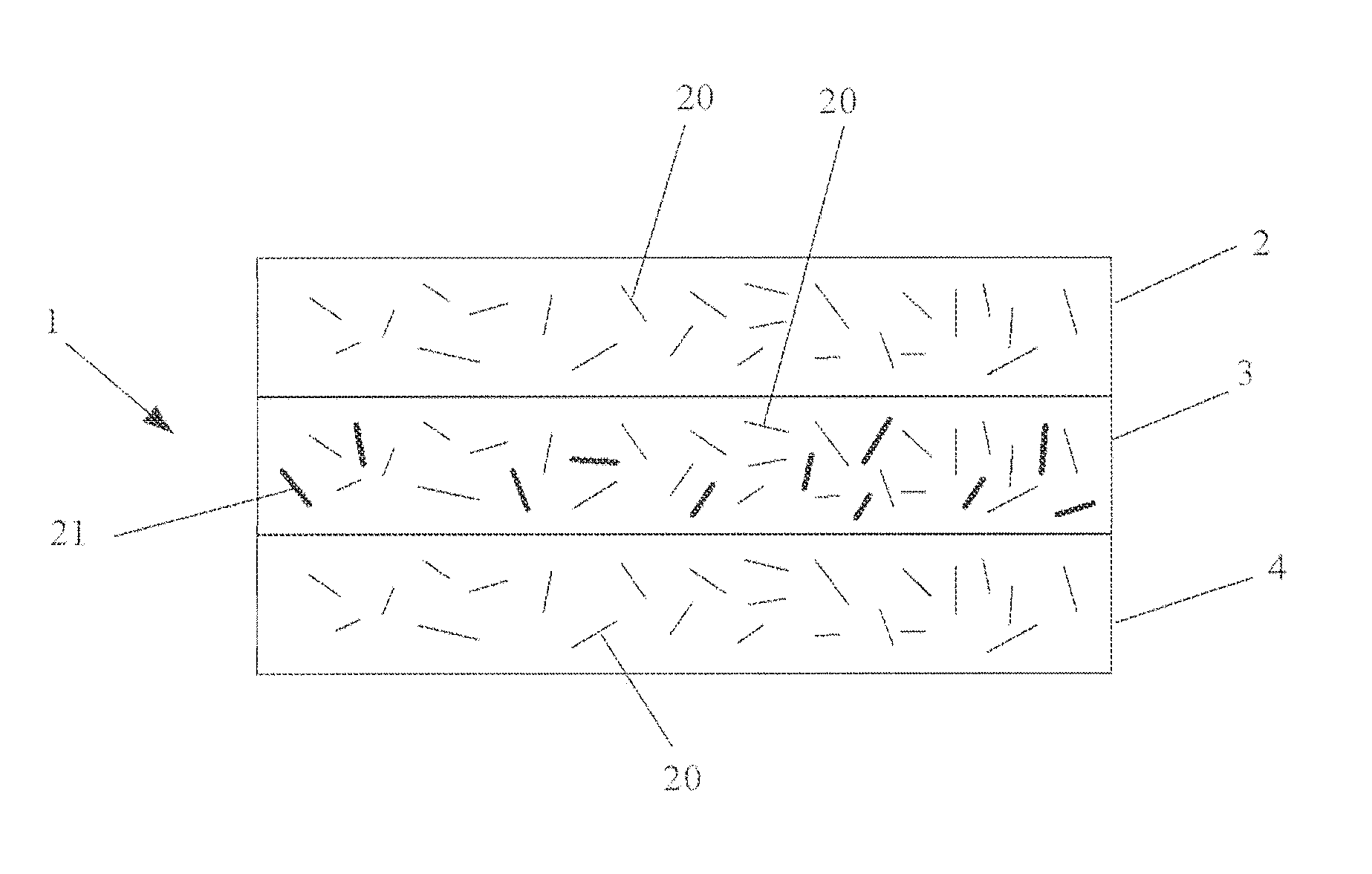

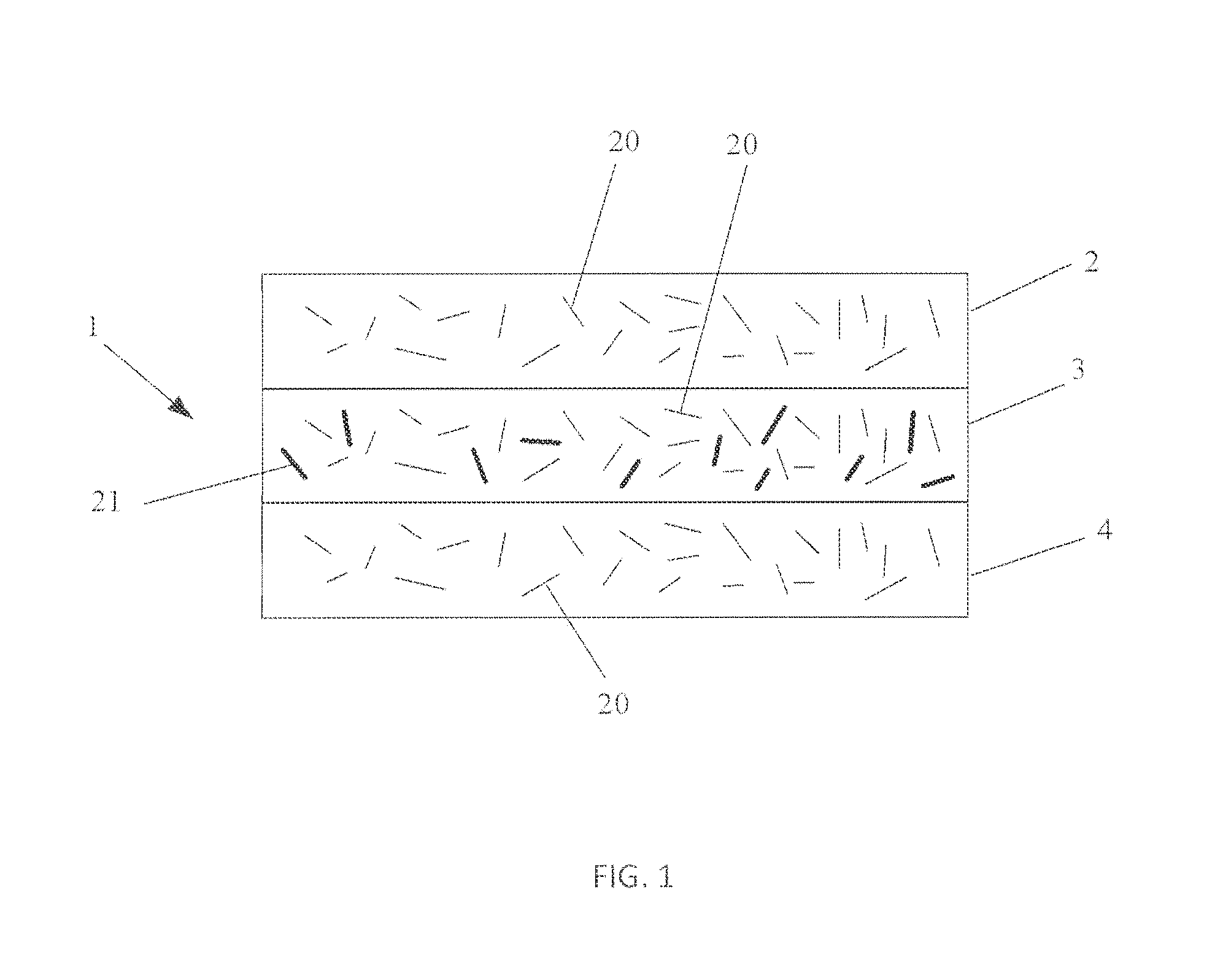

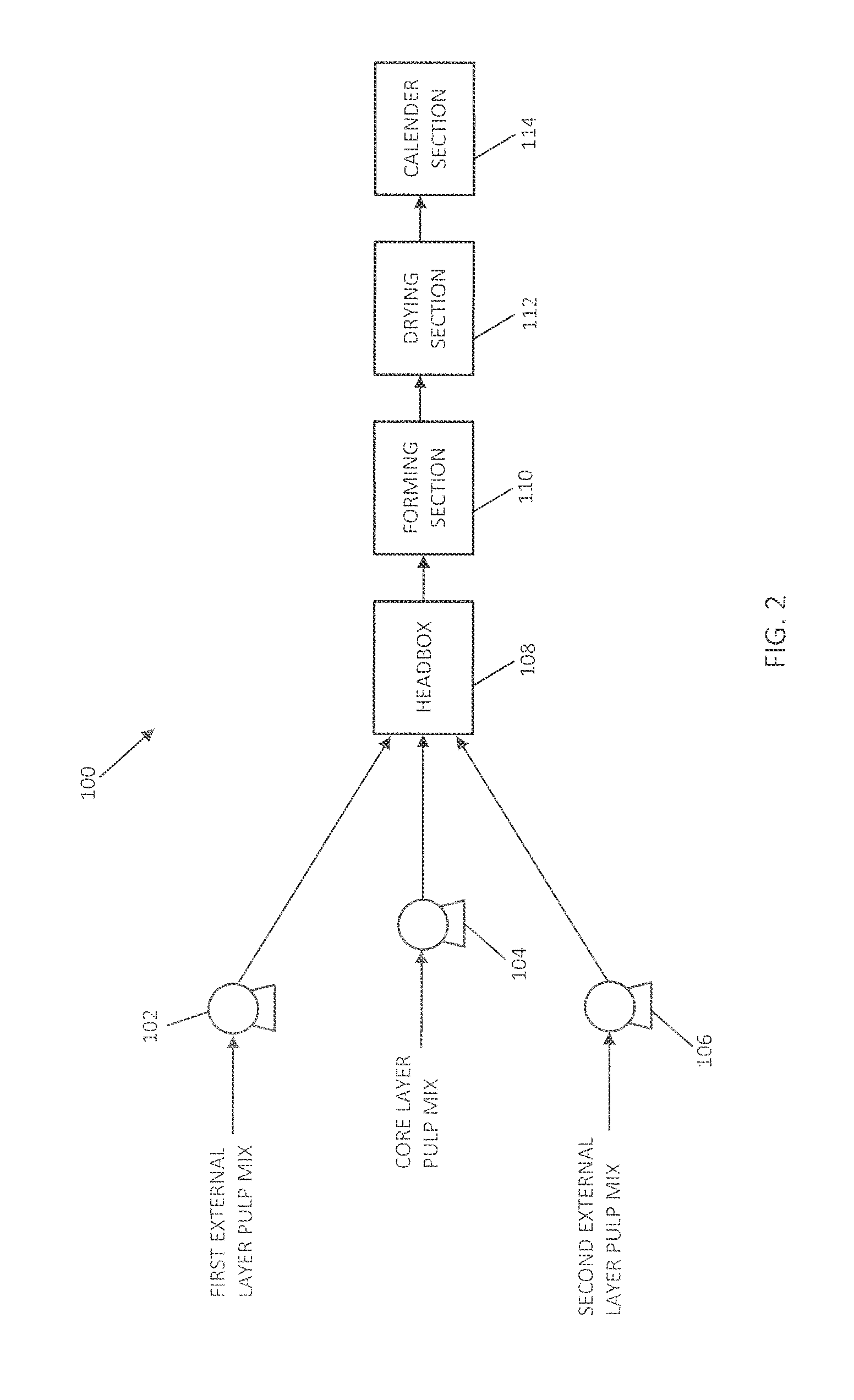

A multi-ply flushable wipe includes a ply having first and second exterior layers and a middle layer disposed therebetween. Each of the exterior layers includes at least 50% by weight natural fibers. When foam-formed, the middle layer includes at least 25% by weight natural fibers. In embodiments, the middle layer may include at least 75% by weight natural fibers. The middle layer also includes synthetic fibers that have a length within the range of 1 mm and 20 mm. The wipe may have a length weight weighted average fiber length of less than 4 mm and a wet CD strength of greater than 20 N / m. Each ply of the wipe may be formed by wetlaying the first and second exterior layers and a foam formed middle layer to form a web, imprinting the web with a structured fabric, and drying the web. The plies are then attached using a binder.

Owner:FIRST QUALITY TISSUE

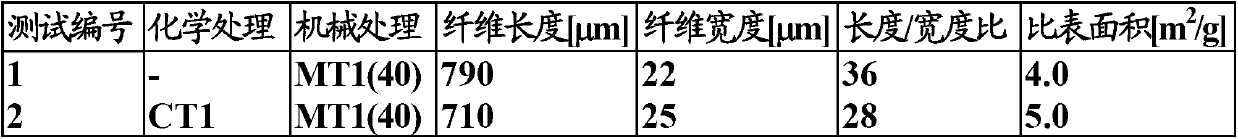

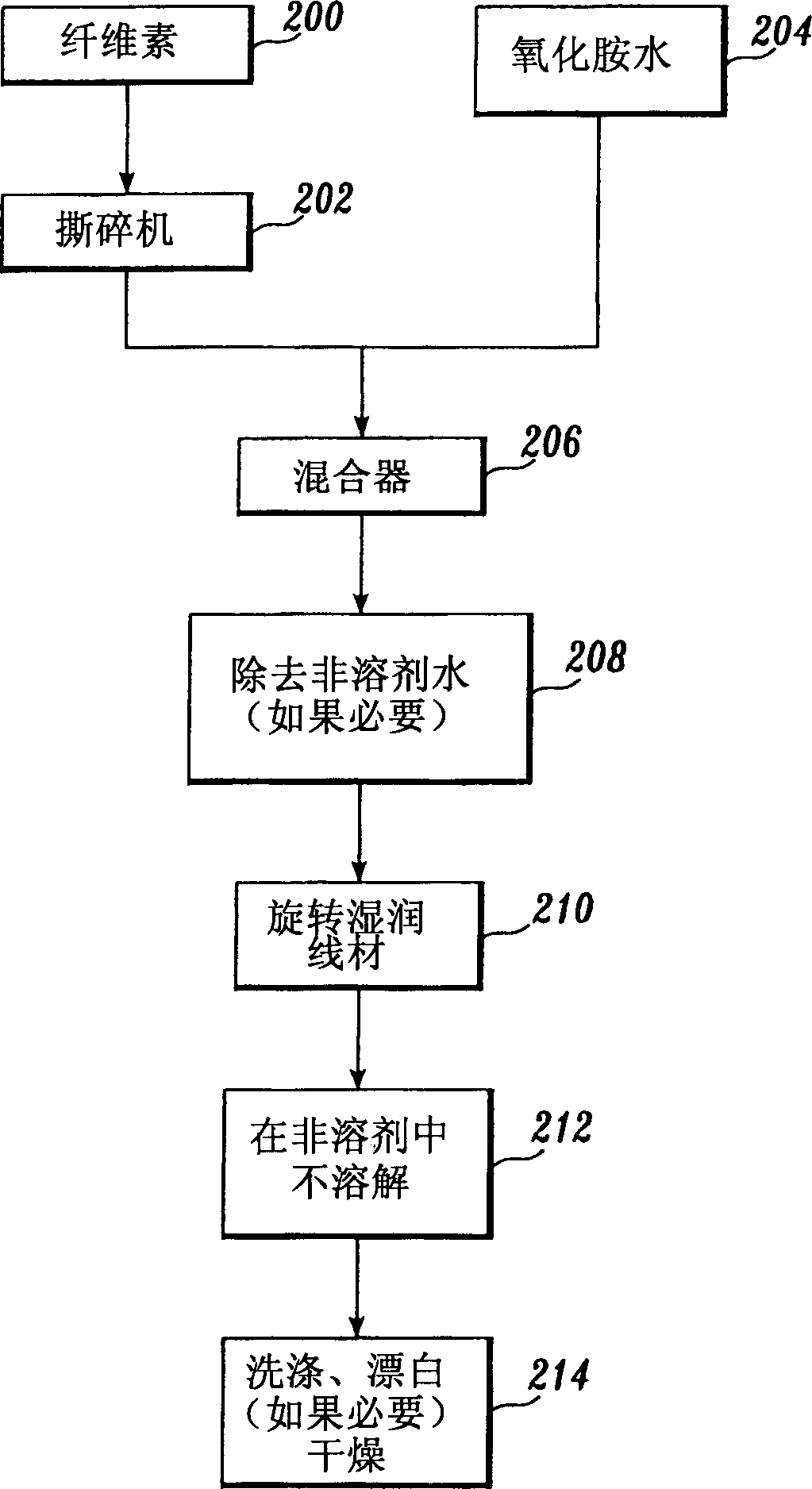

Cellulosic fibre composition

InactiveCN102971462AEasy to prepareWithout significant loss of qualityWood working apparatusPaper/cardboardChemical treatmentNitroxyl radicals

The invention relates to a composition comprising cellulosic fibres having an average degree of substitution of anionic groups of from 0.001 to 0.25, and DEG a length weighted mean fibre length up to 1,100 [mu]m and a length weighted mean fibre width over 10 [mu]m, or DEG a length weighted mean fibre length up to 1,100 [mu]m, and wherein at least 50 % by weight of the cellulosic material is insoluble in water, or DEG a length weighted mean fibre length / width ratio up to 30, or DEG a length weighted mean fibre width over 35 [mu]m. The invention also relates to a composition comprising cellulosic fibres having a specific surface area of at least 1.5 m2 / g, a length weighted mean fibre length / width ratio up to 30, and a dry solids content of at least 5 % by weight, based on the weight of the composition, or up to 30 % by weight, based on the total weight of the cellulosic fibres, of cellulosic fibres with a length weighted mean fibre length up to 100 [mu]m. Method of producing a composition comprising cellulosic fibres which comprises subjecting cellulosic fibres to chemical treatment and mechanical treatment, wherein the chemical treatment comprises treating cellulosic fibres with (i) at least one agent containing a carboxyl group, optionally substituted, (ii) at least one oxidant and at least one transition metal, or (iii) at least one nitroxyl radical, and the mechanical treatment comprises subjecting cellulosic fibres to extrusion with a twin-screw extruder or a planetary roller extruder. The invention also relates to a method of producing a composition comprising cellulosic fibres which comprises subjecting cellulosic fibres having an average degree of substitution of anionic groups of from 0.001 to 0.25 to extrusion. The invention also relates to a composition comprising cellulosic fibres obtainable by the methods, a process for producing a cellulosic pulp mixture which comprises mixing the composition with cellulosic pulp, a cellulosic pulp mixture obtainable by the process, and the use of the composition and cellulosic pulp mixture as an additive in the production of paper and board, processes for producing paper and board in which the composition or cellulosic pulp mixture is used, paper and board obtainable by the processes, and various uses of the paper and board.

Owner:AKZO NOBEL CHEM INT BV

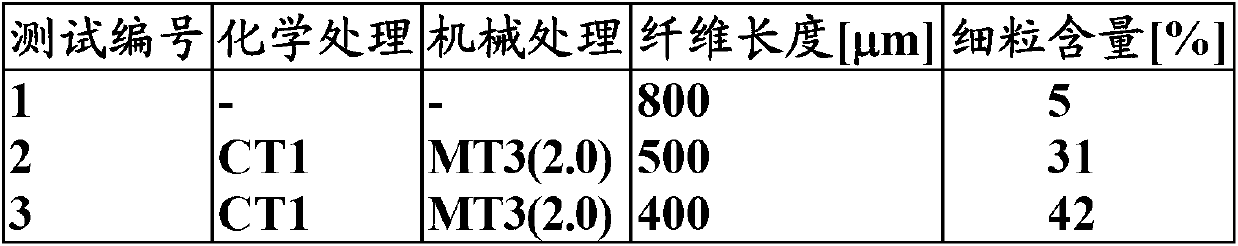

Fingerprint identification method combining point with line

InactiveCN101329727AImprove reliabilityReduce the impactCharacter and pattern recognitionLength weightImage matching

The invention discloses a fingerprint identification method by using the joint of lines and points, which relates to a fingerprint identification method by using the joint of lines and points so as to solve the problems that the existing fingerprint identification method using dot matching easily leads to wrong identification, is greatly affected by fake characteristic points and has relatively poor noise immunity, and the fingerprint identification method using line matching has relatively large calculation work and low identification speed. All matching points in a database image Tp and an image Tq to be identified are selected; sorting is carried out to a plurality of obtained matched points according to matching similarity, and N pairs of matching points with the highest matching similarity are selected; K pairs of matched points are selected from the N pairs of matched points to serve as reference points; the difference between the X-axis and Y-axis and a direction angle is obtained to serve as the offset of two images; translation and rotation transformation are carried out to the image Tq; after correction, the ridge lines of the image Tq and the image Tp mutually match; the matched number is recorded; if the length weighted average value of all matched ridge lines meets a threshold value, the image Tp is identified to match with the image Tq; otherwise, the image Tp is identified not to match with the image Tq.

Owner:HARBIN INST OF TECH

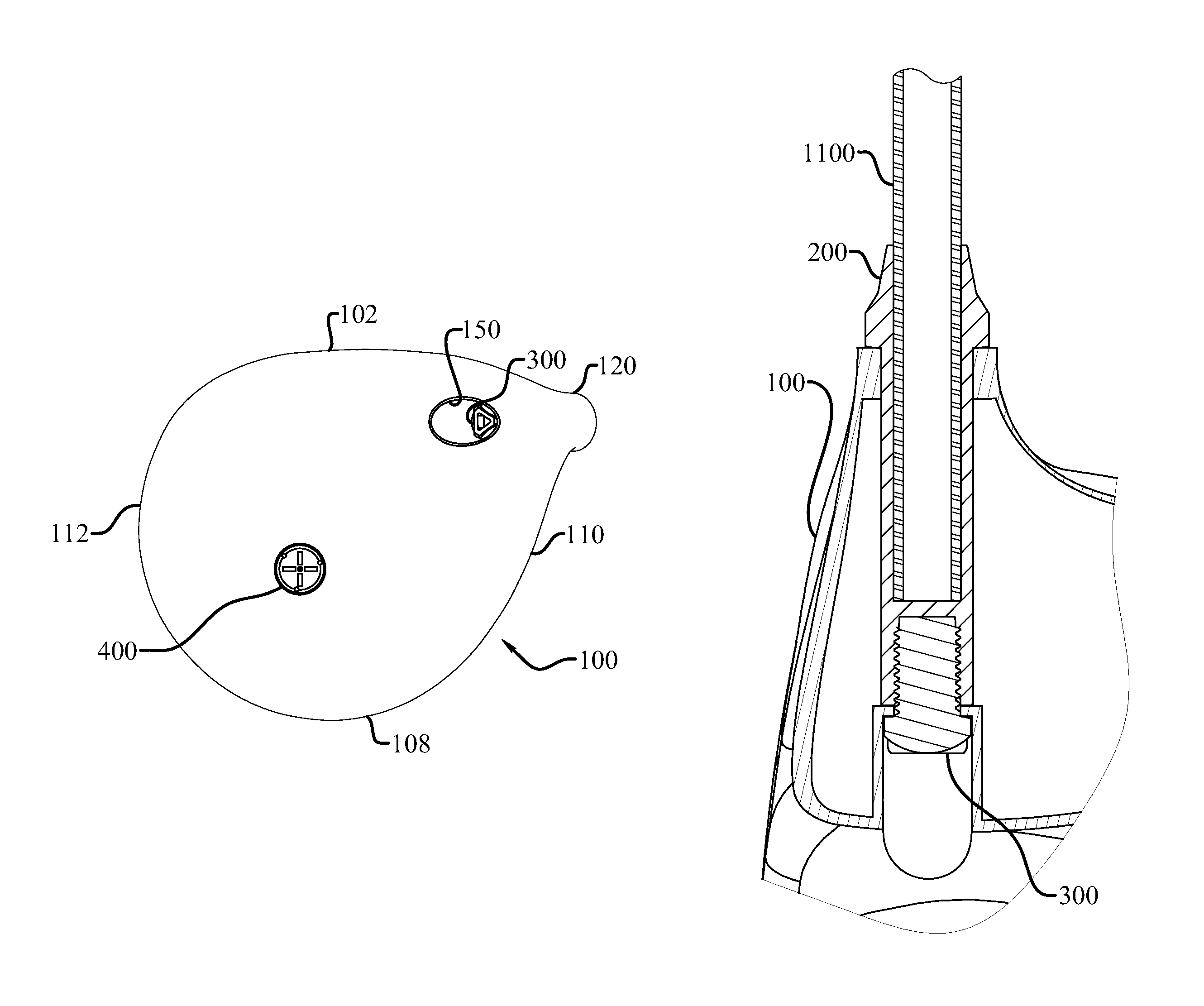

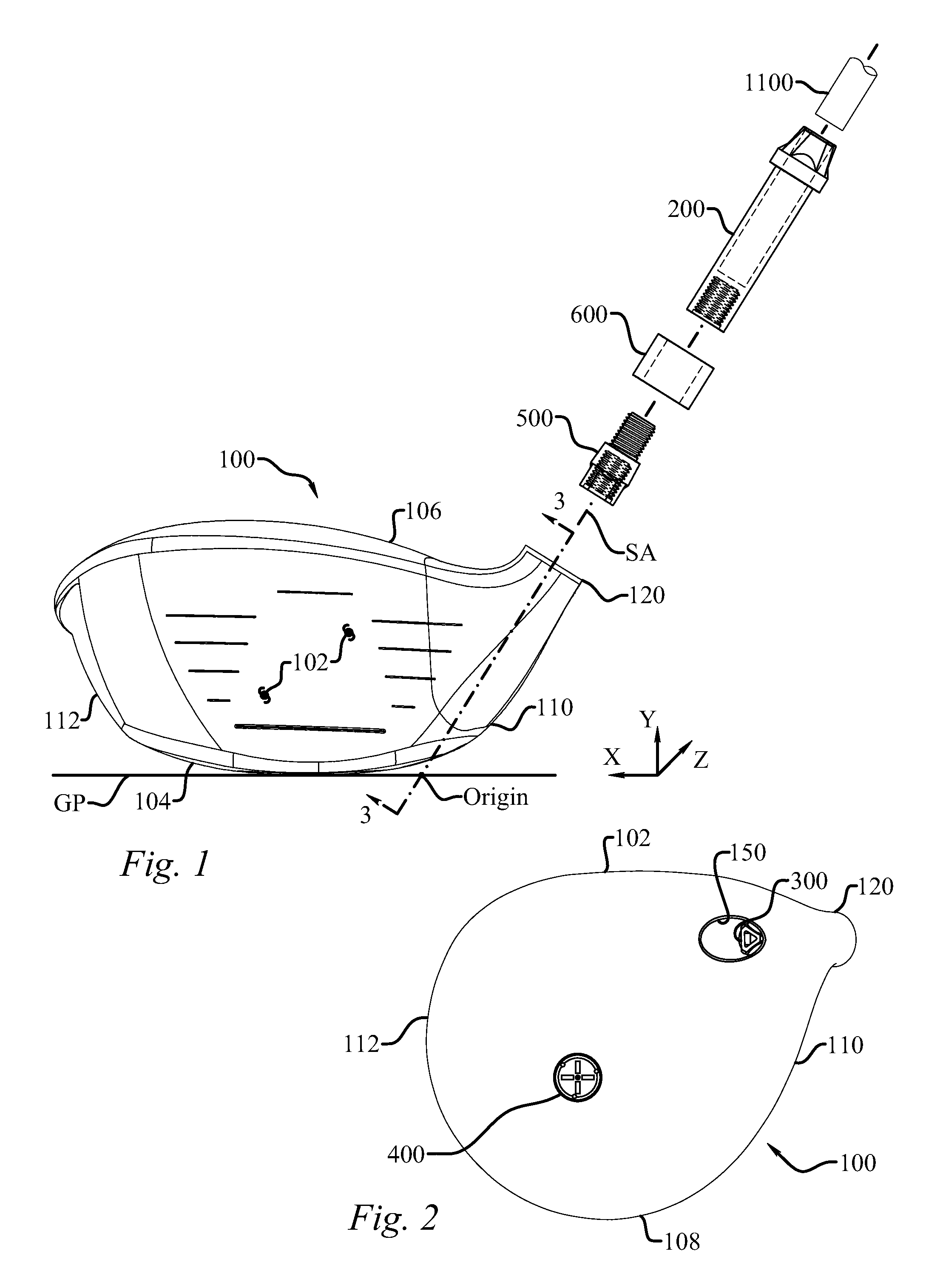

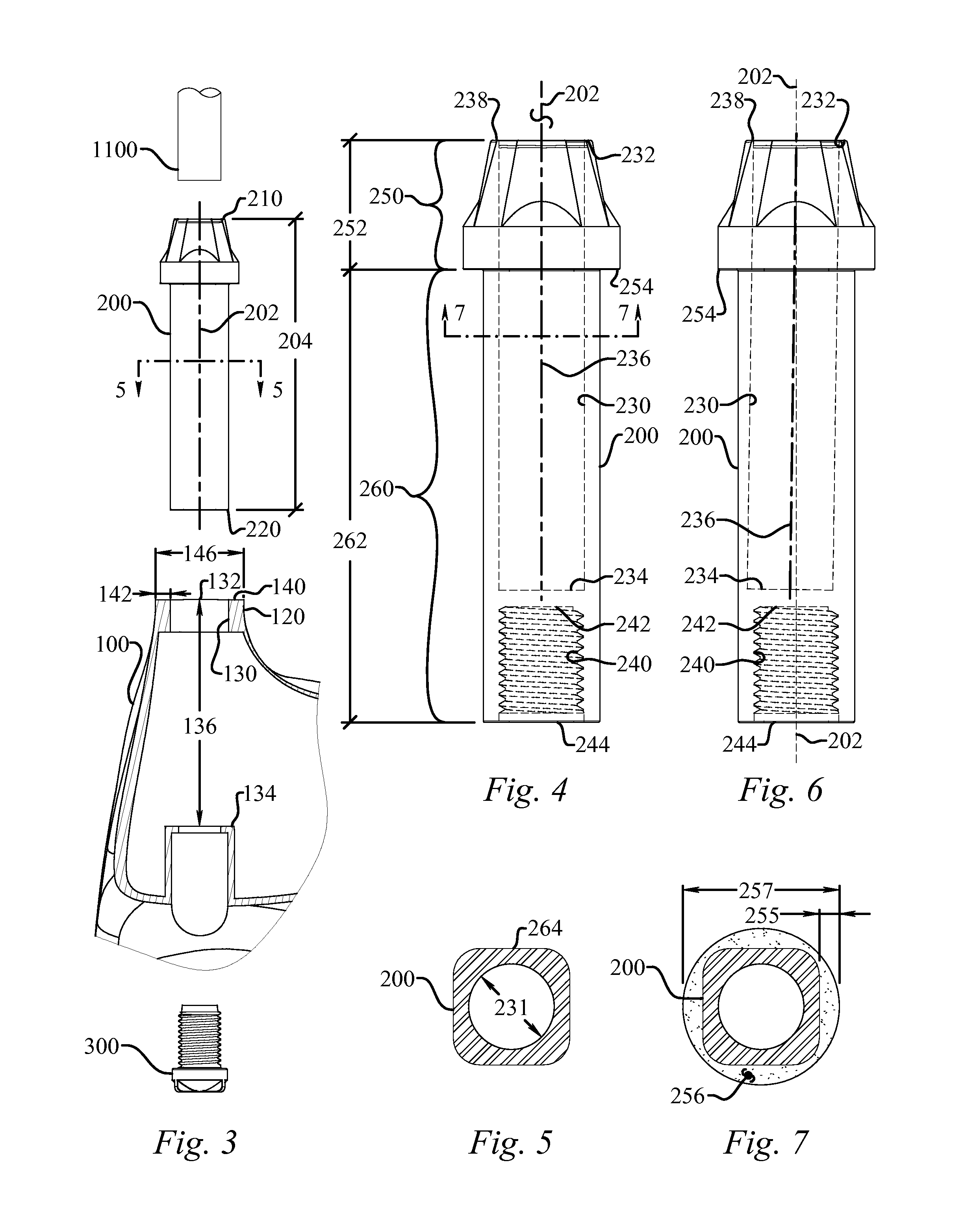

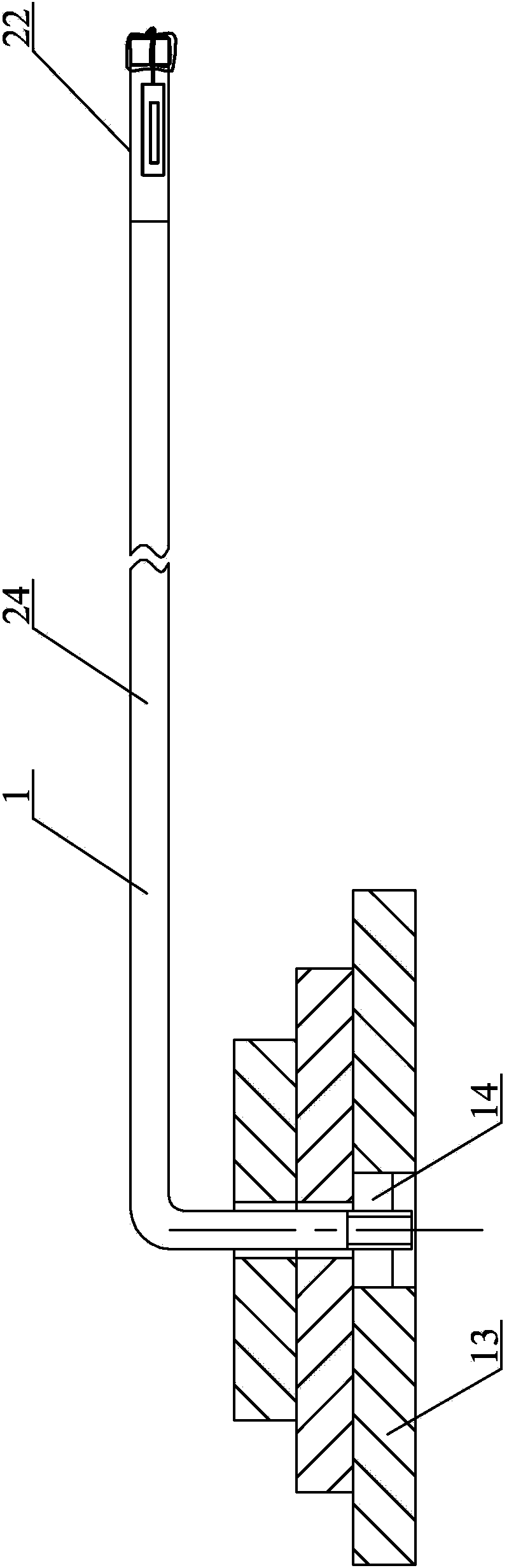

Length adjustment system for joining a golf club head to a shaft

A length adjustment system for joining a golf club head to a shaft is provided. The length adjustment system may be utilized to produce a minor length, an intermediate length, and an extended length of a golf club. In a minor length configuration, the length adjustment system includes a shaft sleeve attached to an end of the shaft. A retainer releasably secures the shaft and shaft sleeve to the golf club head. The minor length configuration also features a minor length weight system. The intermediate length configuration further includes a first spacer, a first hosel sleeve, and an intermediate length weight system. The extended length configuration further includes a second spacer, a second hosel sleeve, and an extended length weight system. The length adjustment system incorporates the discovery of unique relationships among its components so that the resulting golf club has similar characteristics in each configuration.

Owner:TAYLOR MADE GOLF

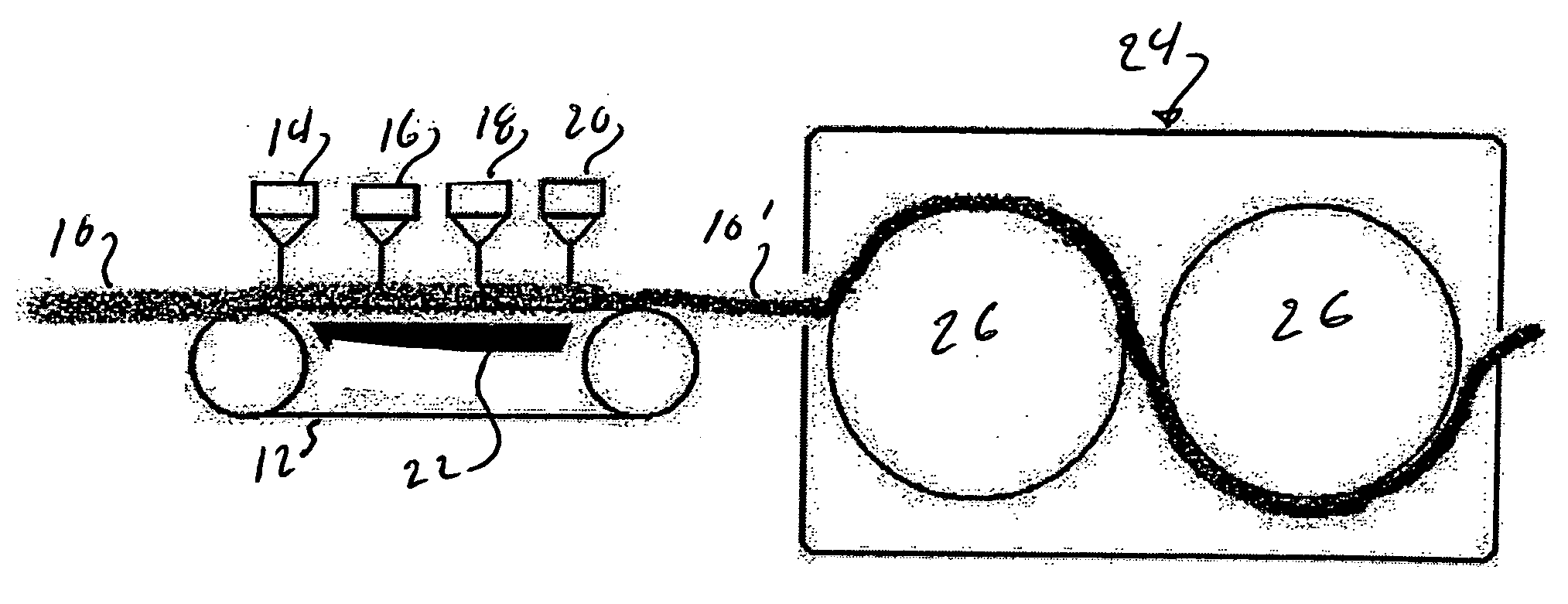

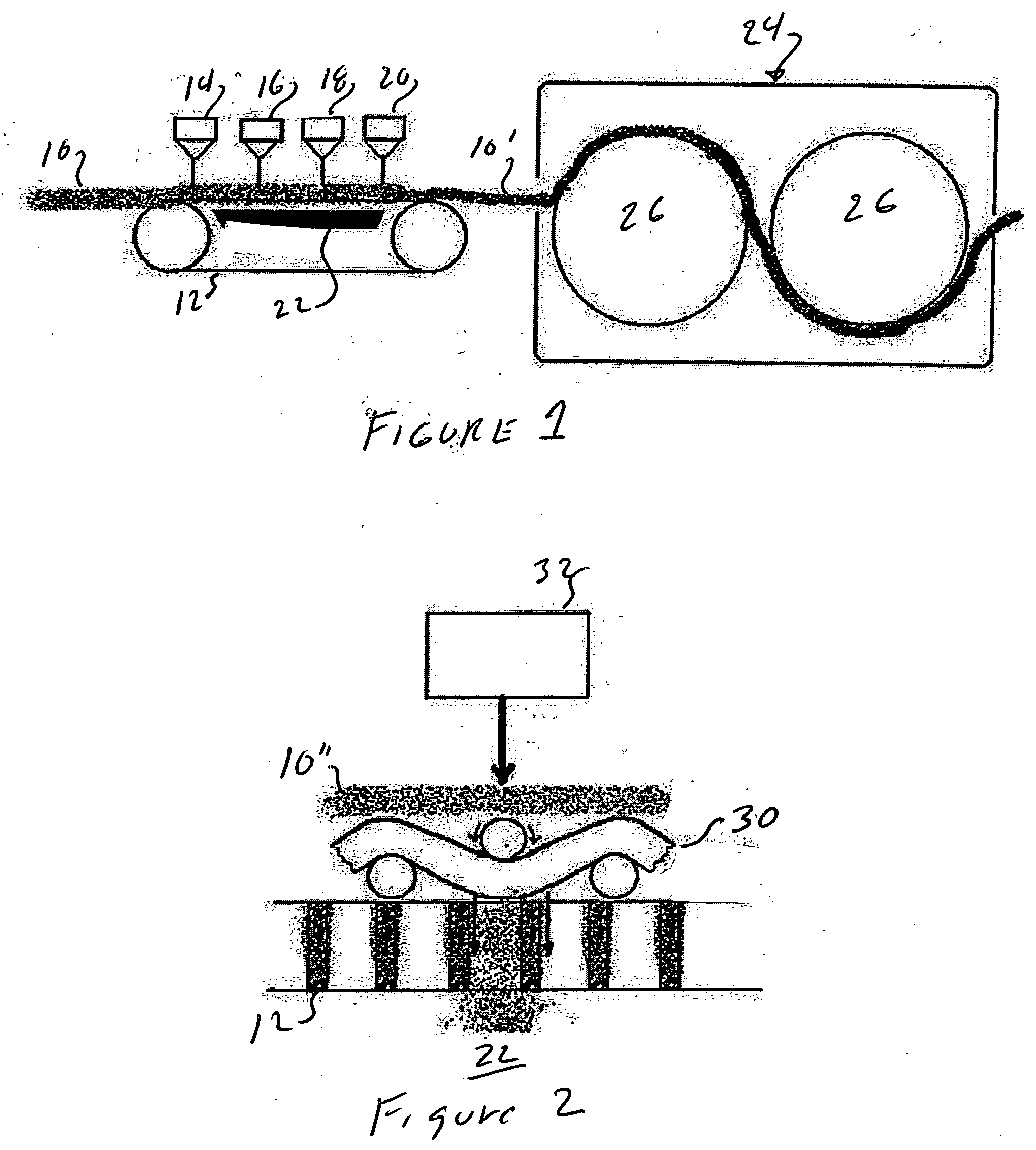

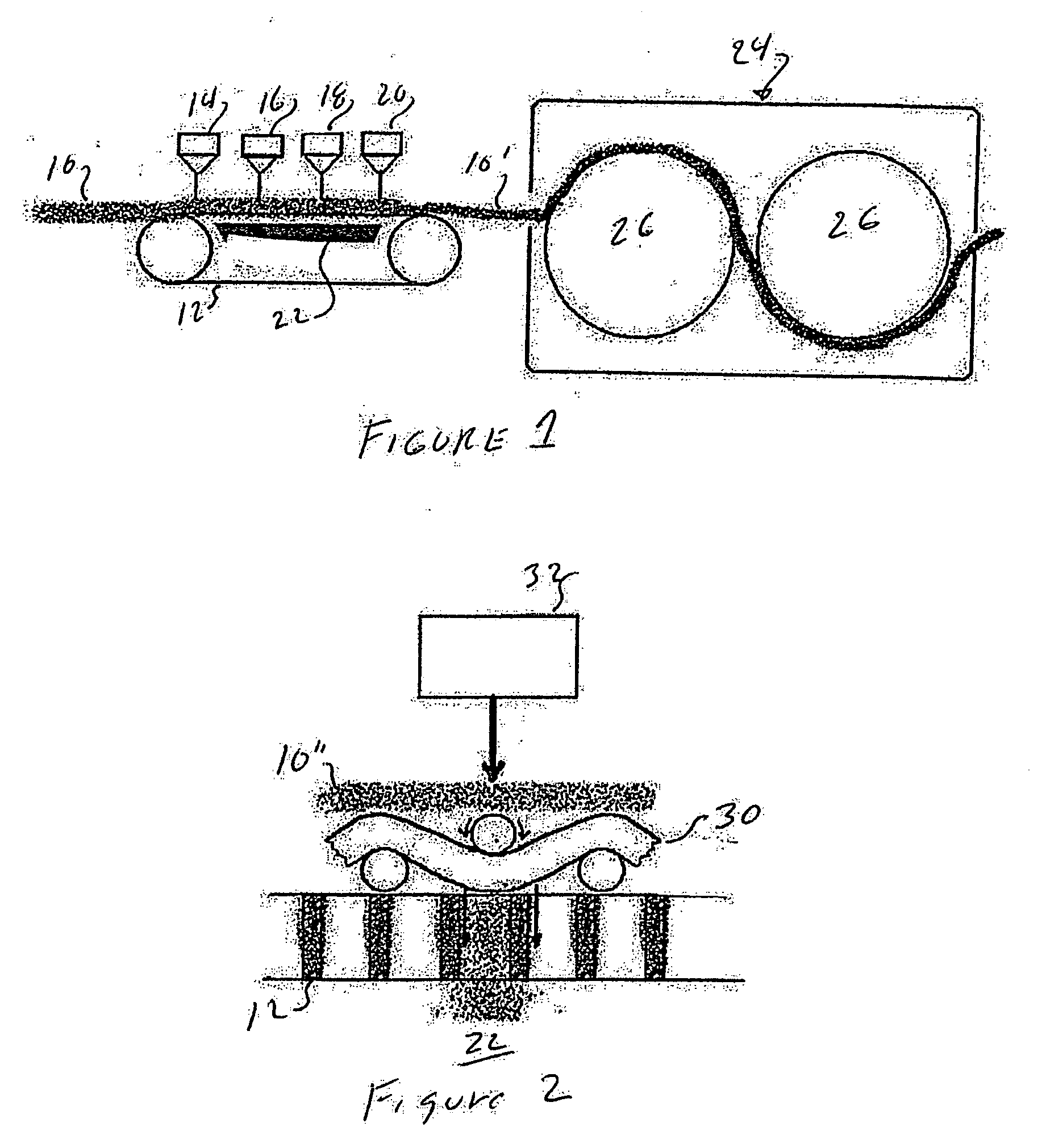

Hydroentangling process

InactiveUS20050278912A1Reduce lossesLess timePattern makingNeedling machinesLength weightCellulose fiber

Owner:WESTLAND JOHN A +1

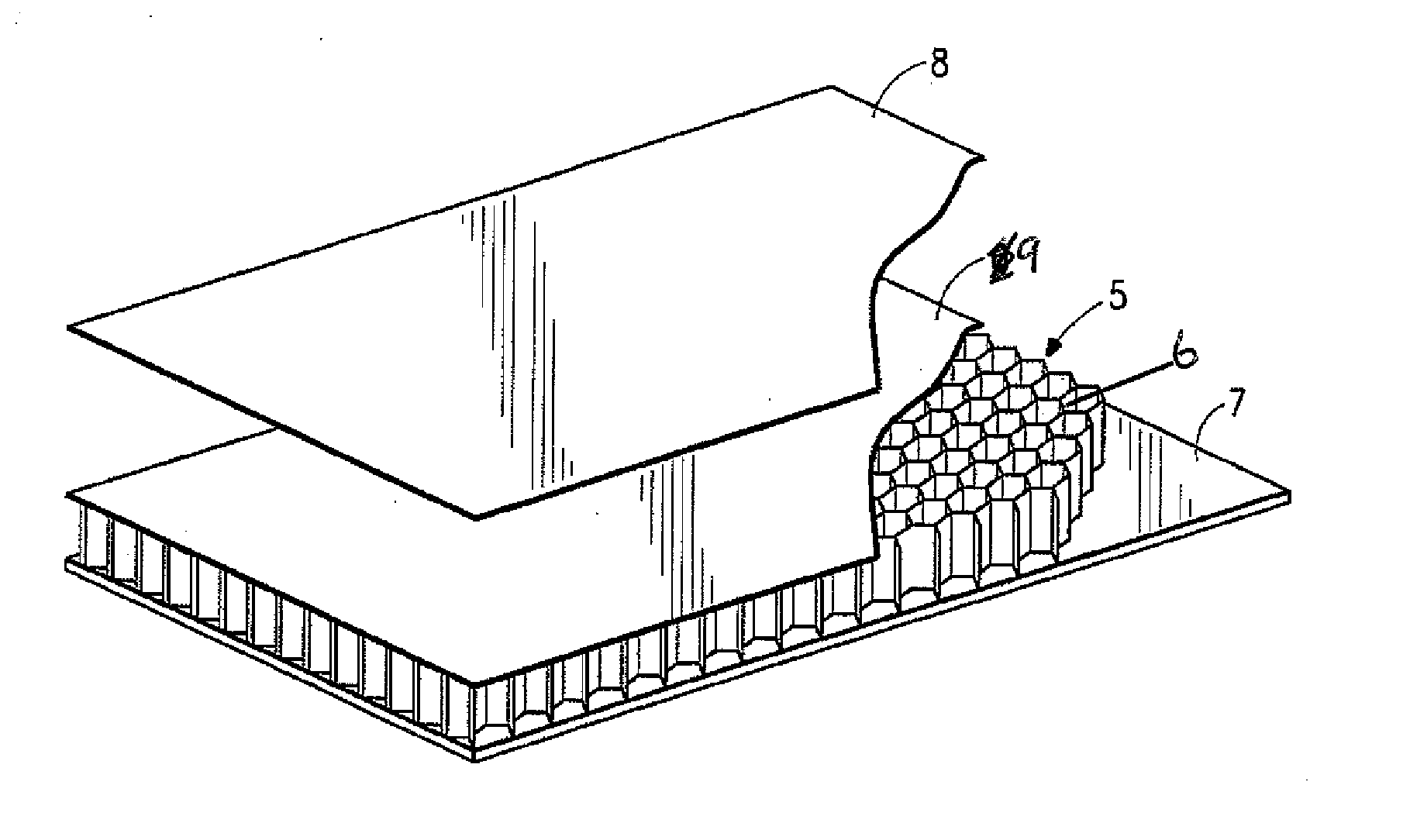

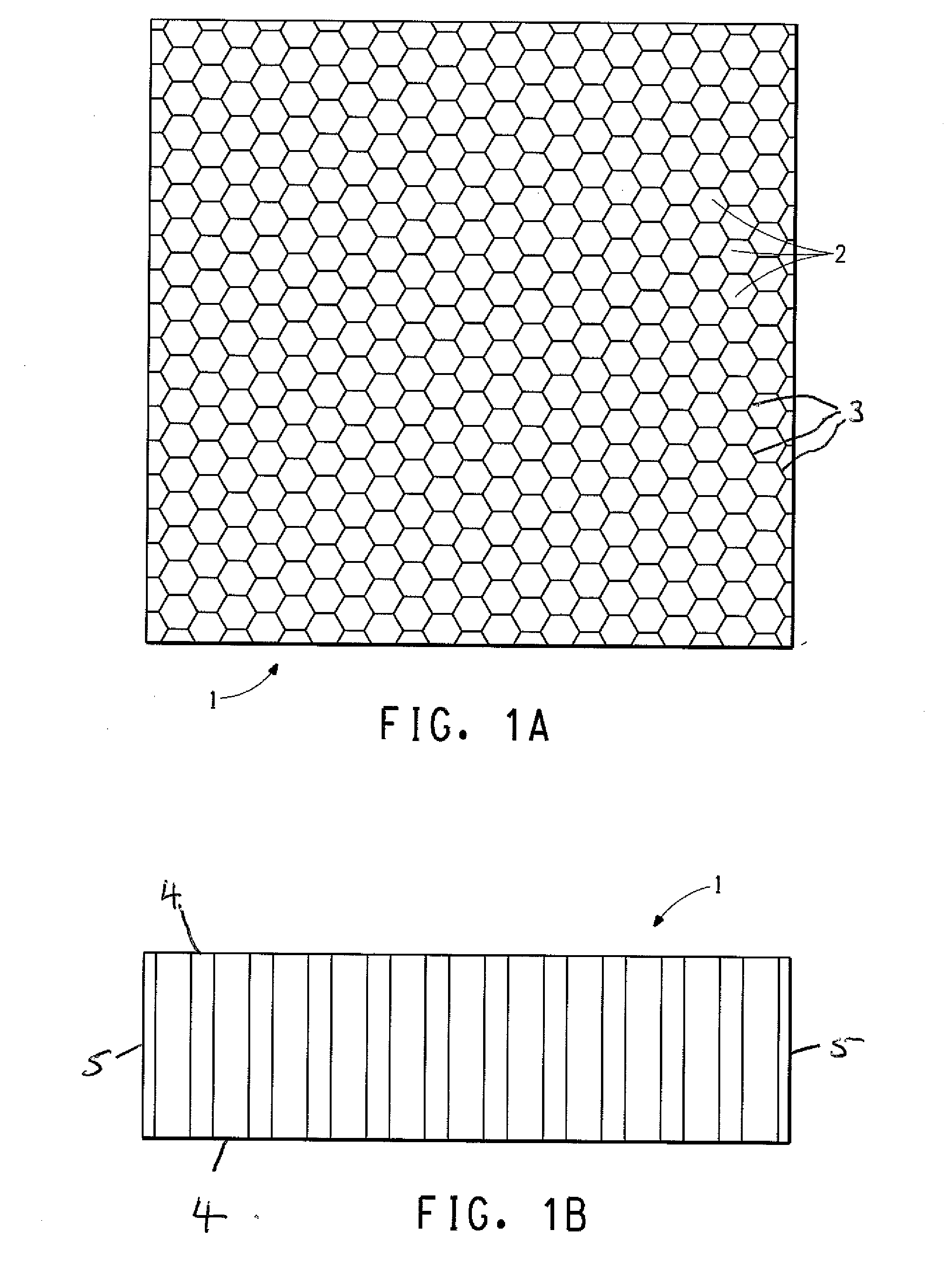

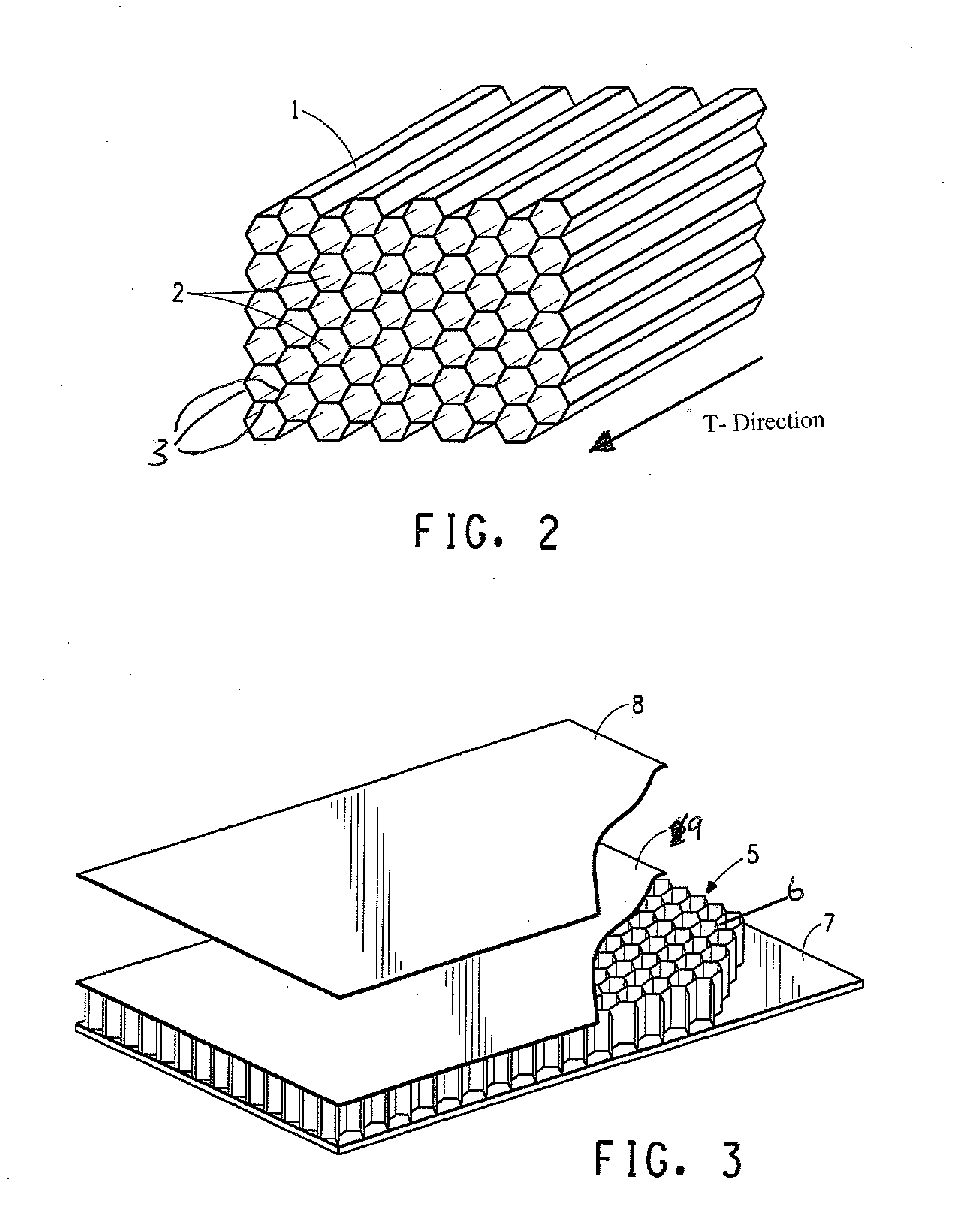

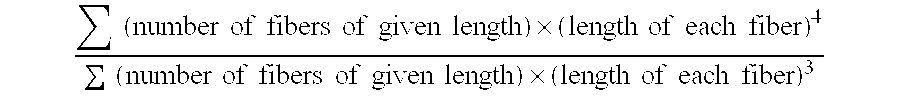

Honeycomb core based on carbon fiber paper and articles made from same

InactiveUS20110281063A1Synthetic resin layered productsPaper/cardboard layered productsFiberCarbon fibers

This invention relates to a honeycomb core made from paper comprising 20-85 weight percent of carbon fiber floc. The carbon fibers have a non-round cross sectional aspect ratio of at least 1.5:1. The paper has a fiber volume fraction of at least 35%. The arithmetic mean length of the carbon fibers is at least 0.5 mm. and a length weighted mean length of at least 0.9 mm.

Owner:EI DU PONT DE NEMOURS & CO

Micropulp for filters

InactiveUS7624879B2Synthetic resin layered productsLoose filtering material filtersFiberPolymer science

A filter made from a blend of a polymeric fibrous pulp having a length weighted average fiber length between 0.5 and 1.1 mm and a polymeric fibrous micropulp having a volume weighted average fiber length between 1.0-200.0 micrometers in which the ratio of average fiber length of the fibrous pulp to fibrous micropulp is greater than or equal to about 4:1.

Owner:EI DU PONT DE NEMOURS & CO

Micropulp for filters

InactiveUS20090145842A1Synthetic resin layered productsLoose filtering material filtersFiberPolymer science

A filter made from a blend of a polymeric fibrous pulp having a length weighted average fiber length between 0.5 and 1.1 mm and a polymeric fibrous micropulp having a volume weighted average fiber length between 1.0-200.0 micrometers in which the ratio of average fiber length of the fibrous pulp to fibrous micropulp is greater than or equal to about 4:1.

Owner:EI DU PONT DE NEMOURS & CO

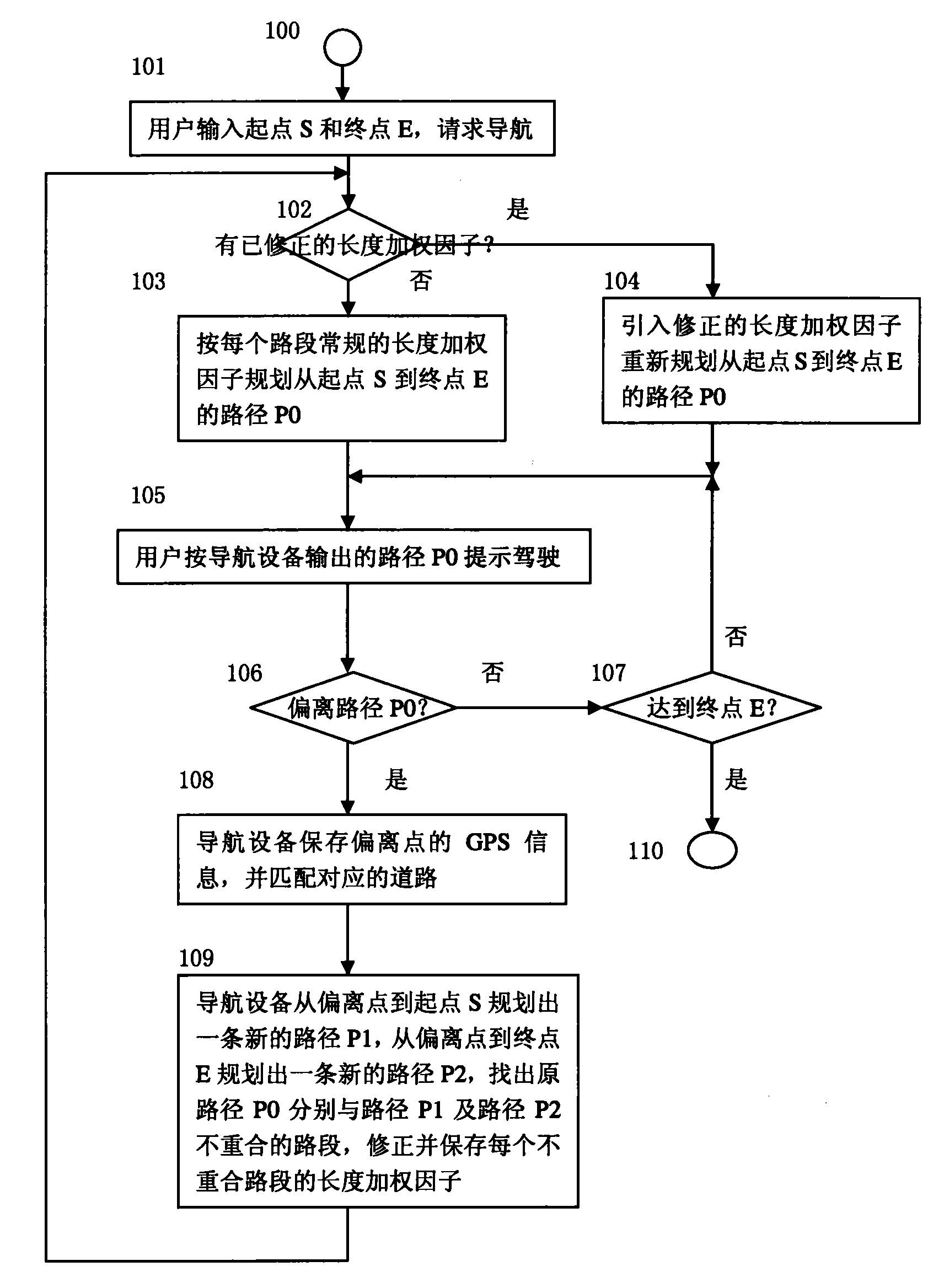

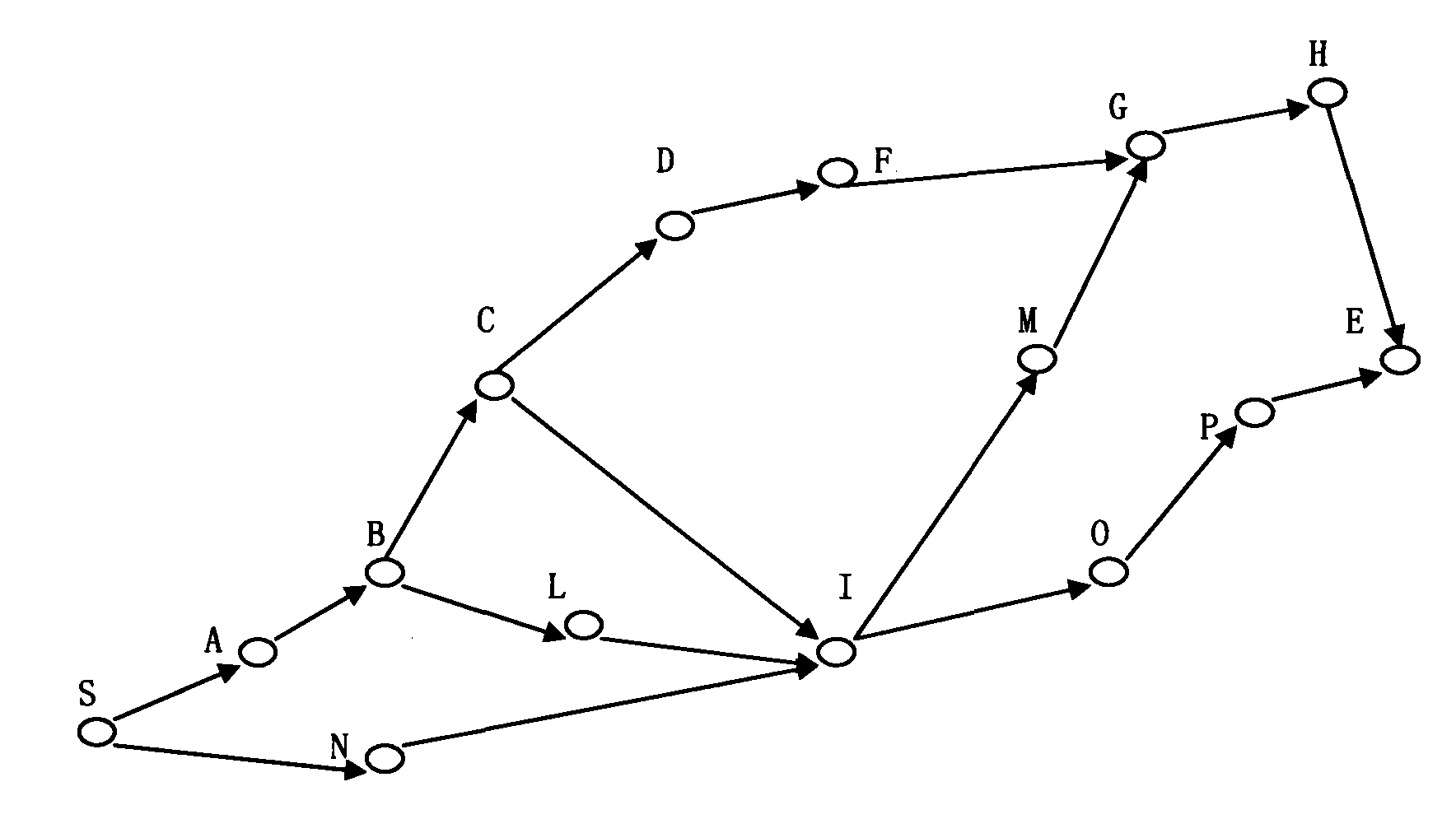

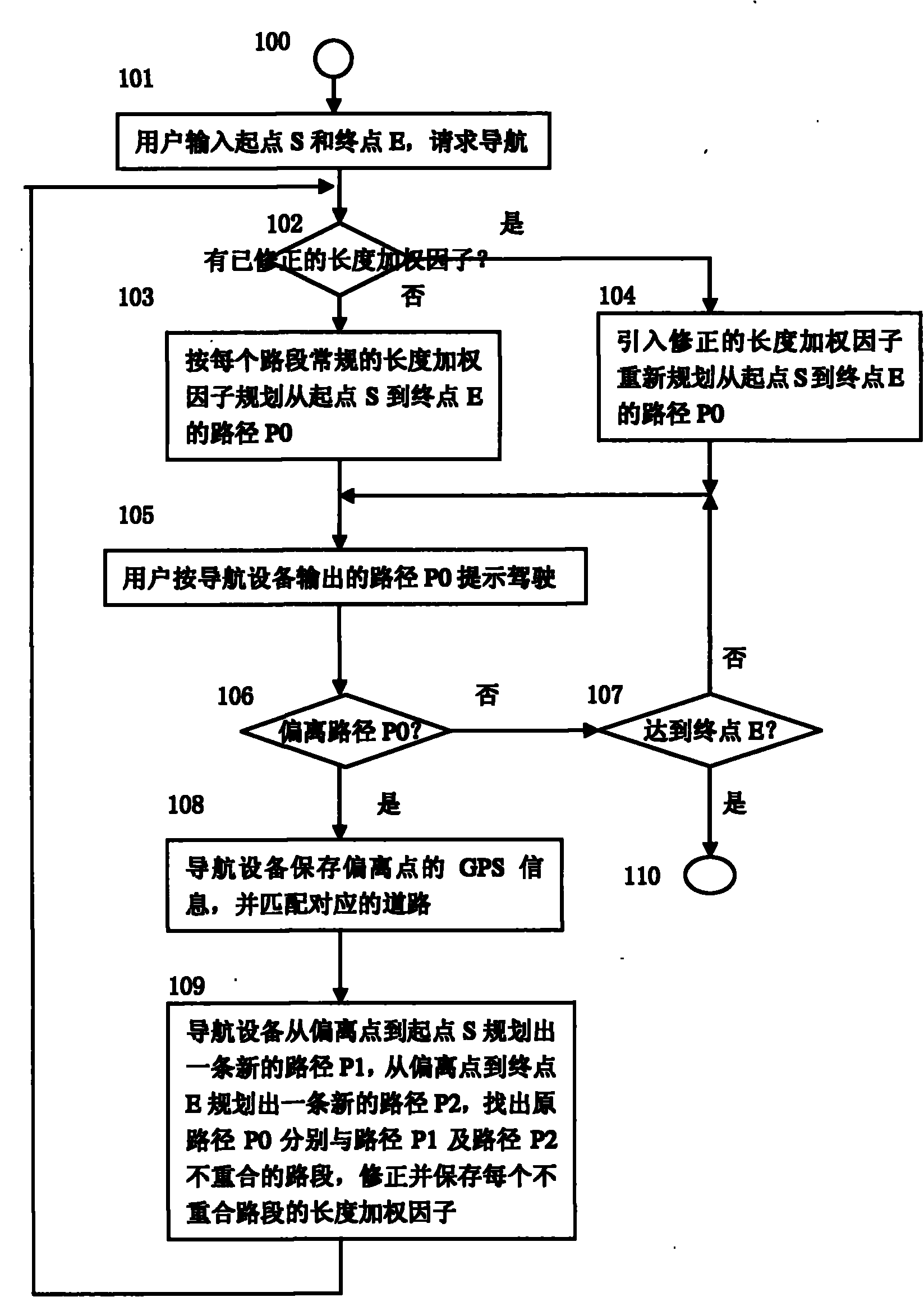

Navigation path planning method

ActiveCN101776458AShort reckoning lengthInstruments for road network navigationPath lengthLength weight

The invention discloses a navigation path planning method, relating to a method for path navigation equipment to plan a navigation path and navigate. The method can be used to learn the driving custom of a user. The navigation equipment is stored with an electronic map of each road section length weight coefficient and plans the navigation path according to a shortest path rule. The equipment plans a path P0 from a starting point S to an end point E according to each road section length weight coefficient; a user drives according to the path P0 prompted and output by the equipment; the equipment detects whether the user deviates from the path P0 according to real-time GPS data; and if so, the GPS information of a deviating point is stored, a path P1 is planned from the deviating point to the starting point S, a path P2 is planned from the deviating point to the end point E, the misaligned road sections of the source path P0, the path P1 and the path P2 are found, and a coefficient which is less than 1 is used for correcting the length weight coefficient of each misaligned road section, and the corrected length weight coefficient is stored; and the equipment replans the path P0 from the starting point S to the end point E and prompts the users to drive according to the new path P0.

Owner:XIAMEN YAXON NETWORKS CO LTD

Carbon fiber-resin composite core for overhead cable

ActiveCN101908391AReduce weight per unit lengthImproves crush resistanceInsulated cablesInsulating bodiesFiberState of art

The invention relates to a carbon fiber-resin composite core for overhead cables, which consists of a carbon fiber-resin composite core layer and a protective layer wound on the core layer, wherein the protective layer is a fibrofelt and / or fiber fabric-reinforced resin material layer. Compared with the prior art, the carbon fiber-resin composite core for the overhead cables has the advantages of reducing the unit length weight of a product and improving flattening resistance.

Owner:嘉兴宝盈通复合材料有限公司

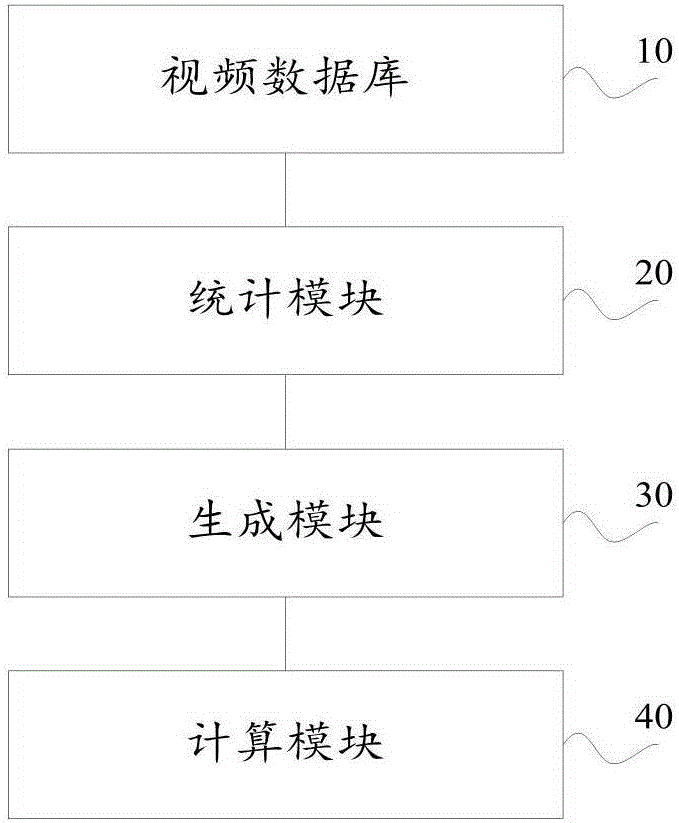

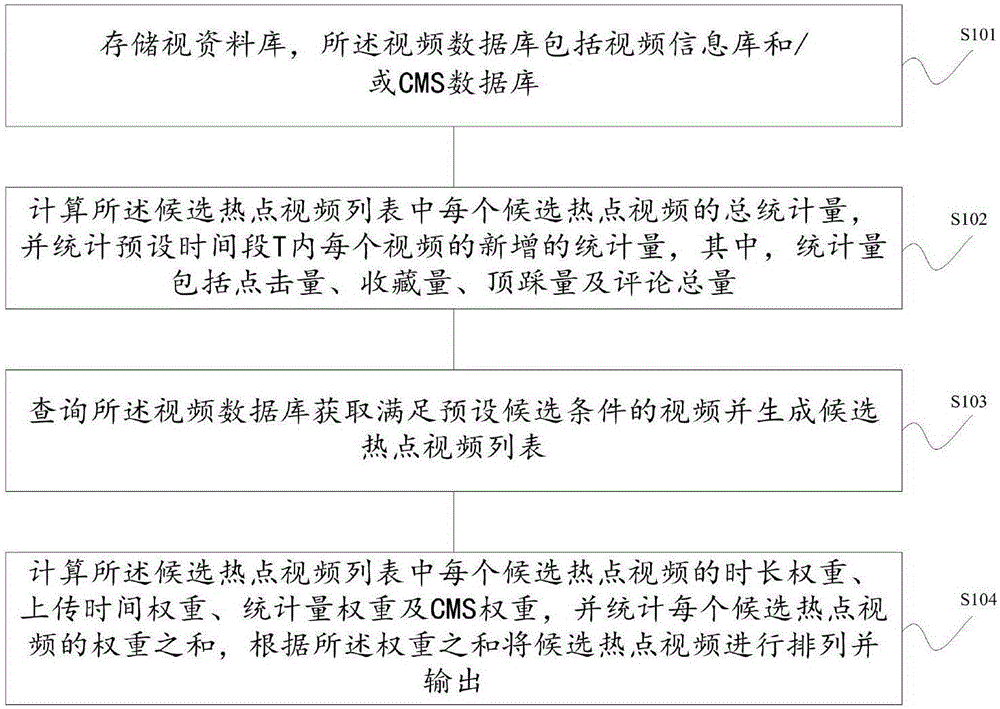

System and method for automatically predicting hot videos

InactiveCN106339447AMeets requirementsImprove digging efficiencySelective content distributionSpecial data processing applicationsComputer terminalLength weight

The invention discloses a system and a method for automatically predicting hot videos. The system comprises a video database, a counting module, a generation module and a calculation module, wherein the counting module is used for calculating a total counting amount of each candidate hot video in a candidate hot video list, and counting a new counting amount of each video within a preset time section T; the generation module is used for checking the video database, acquiring videos meeting preset candidate conditions, and generating the candidate hot video list; the calculating module is used for calculating the time length weight, the uploading time weight, the counting amount weight and the CMS weight of each candidate hot video in the candidate hot video list, counting the sum of the weights of each candidate hot video, and arranging and outputting candidate hot videos according to the sum of the weights. By adopting the system and the method, after the weights of candidate hot videos acquired by a hot video recommendation module are calculated, a list of recent hot videos can be generated according to calculation results, and the list can be recommended to a terminal user to use.

Owner:DATAGRAND TECH INC

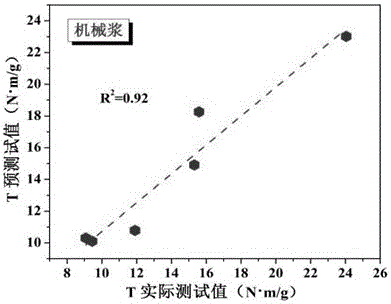

Method for predicting paper tensile strength based on mechanical pulp fiber properties

InactiveCN105868550AAchieve the purpose of forecastingPaper testingInformaticsFiberMathematical model

The invention relates to a method for predicting paper tensile strength based on mechanical pulp fiber properties and belongs to the technical field of pulping and papermaking. On the basis of a classic page model, the water retention value WRV of pulp is used for replacing the fiber relative bonded area RBA which is hard to test, and a mathematical model suitable for evaluating the relation between the mechanical pulp fiber properties and the paper tensile strength is established. Specifically, mechanical pulp fibers are used as samples, and mechanical pulp plates made of different varieties of trees (polar and maple) are subjected to defibering and PFI pulping; assuming that the model contains the paper tensile index T, the fiber length weighted lw, the fiber curling index, the shear bond strength b between the fibers and the water retention value WRV of the pulp, the expression of a paper tensile strength model is shown in the description, wherein a is constant. The method is completely based on the morphological parameters of the mechanical pulp fibers, and efficient prediction of the paper tensile strength can be realized by testing the fiber morphological parameters.

Owner:ZHEJIANG SCI-TECH UNIV

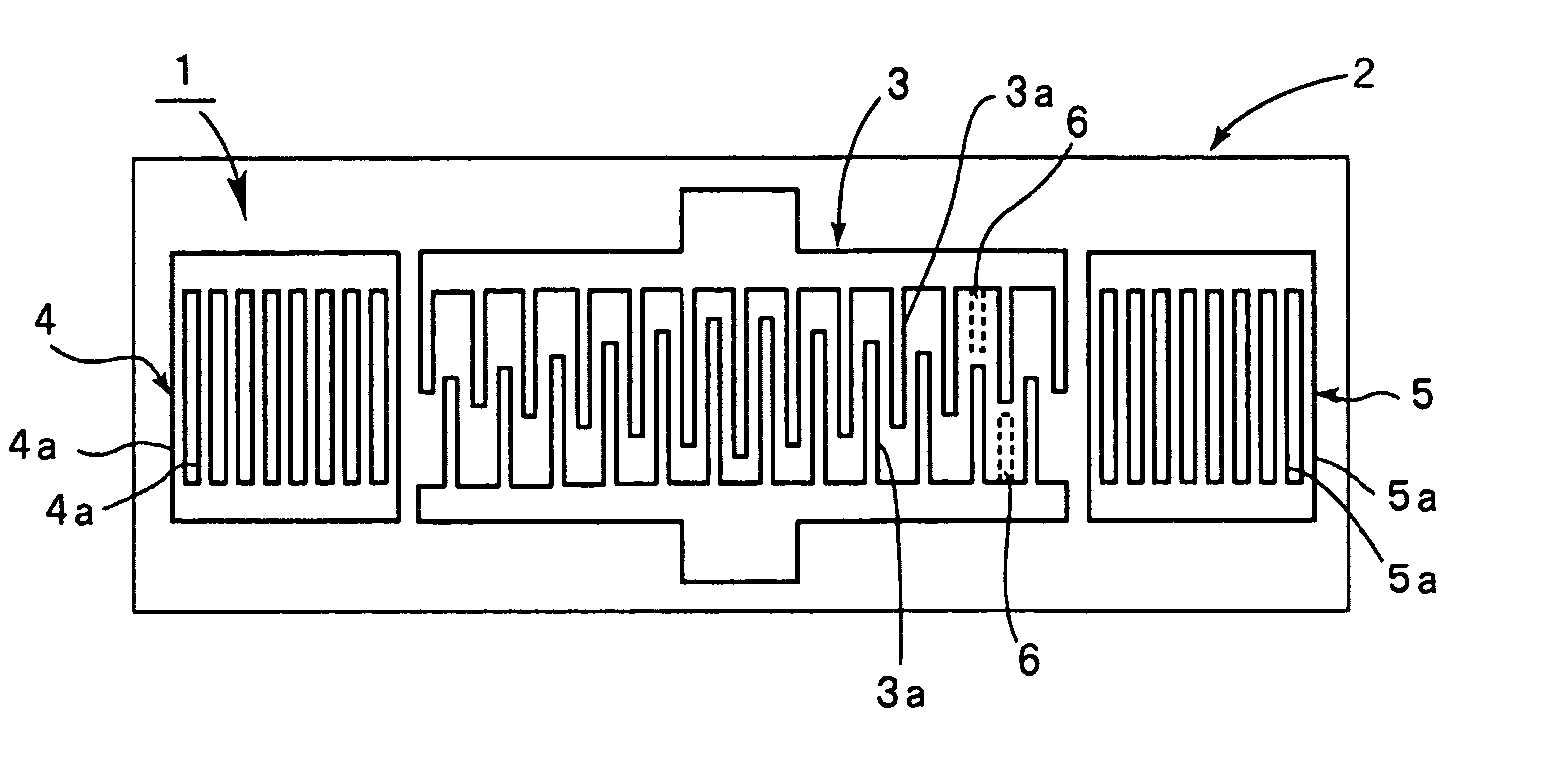

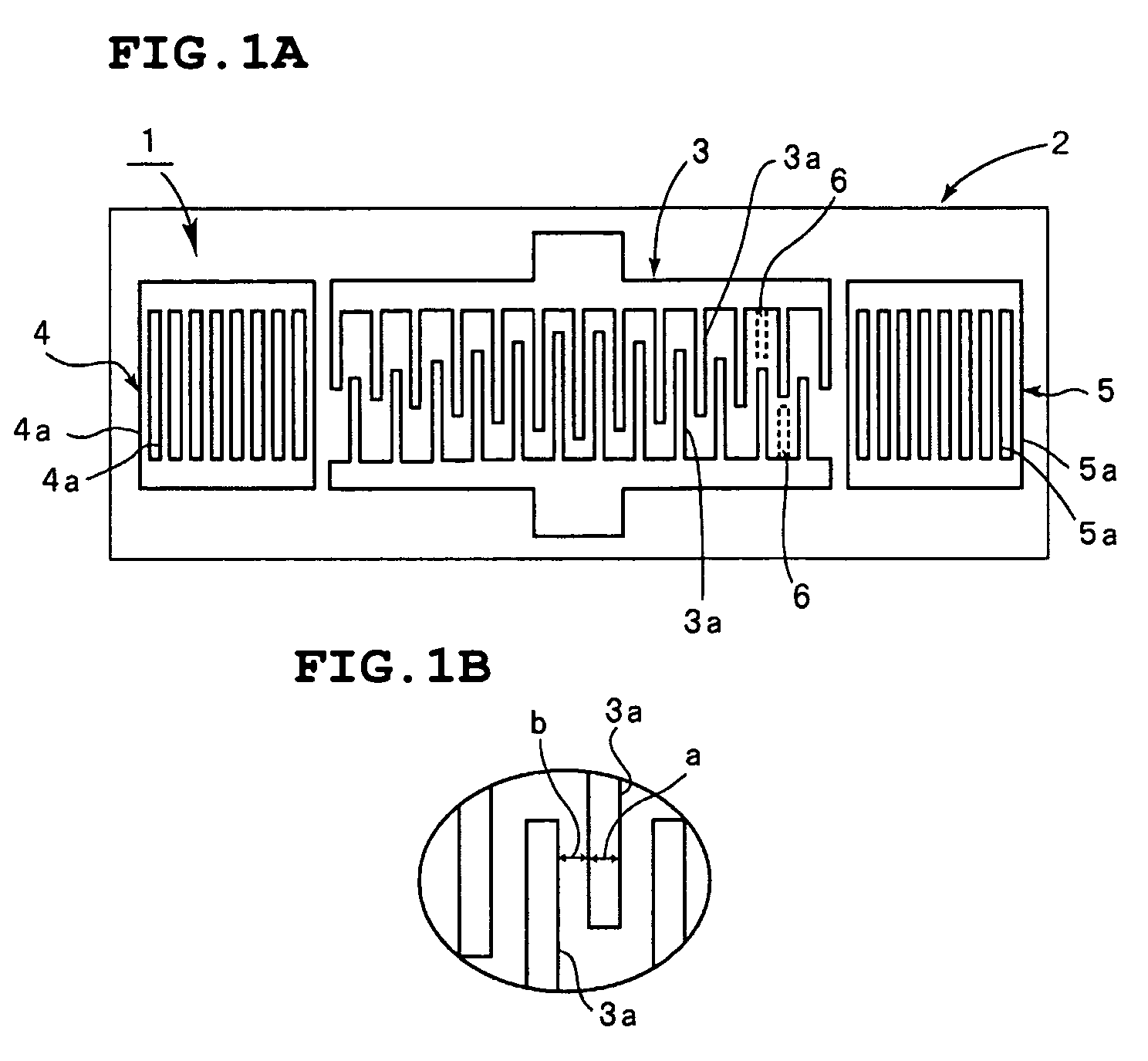

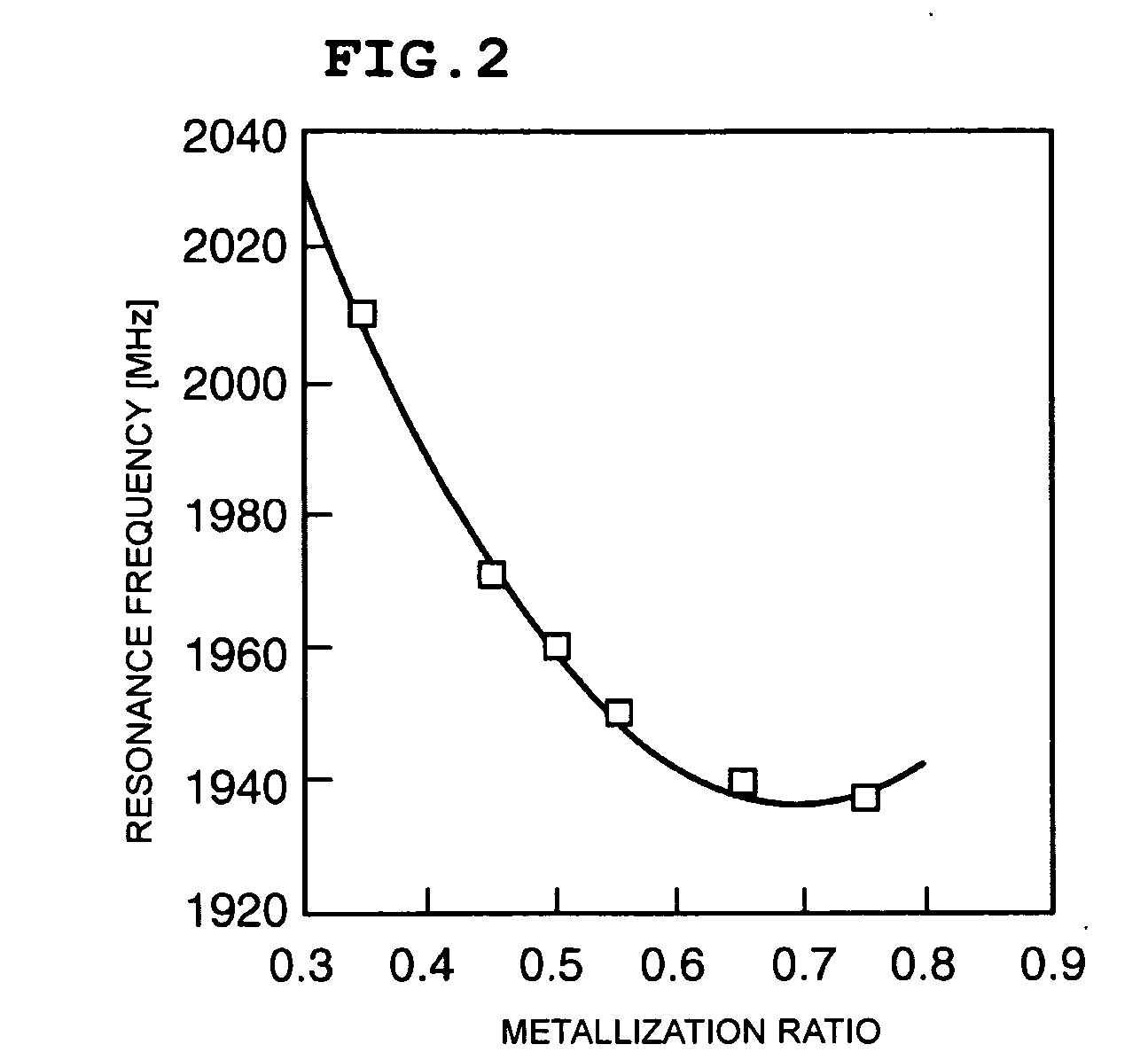

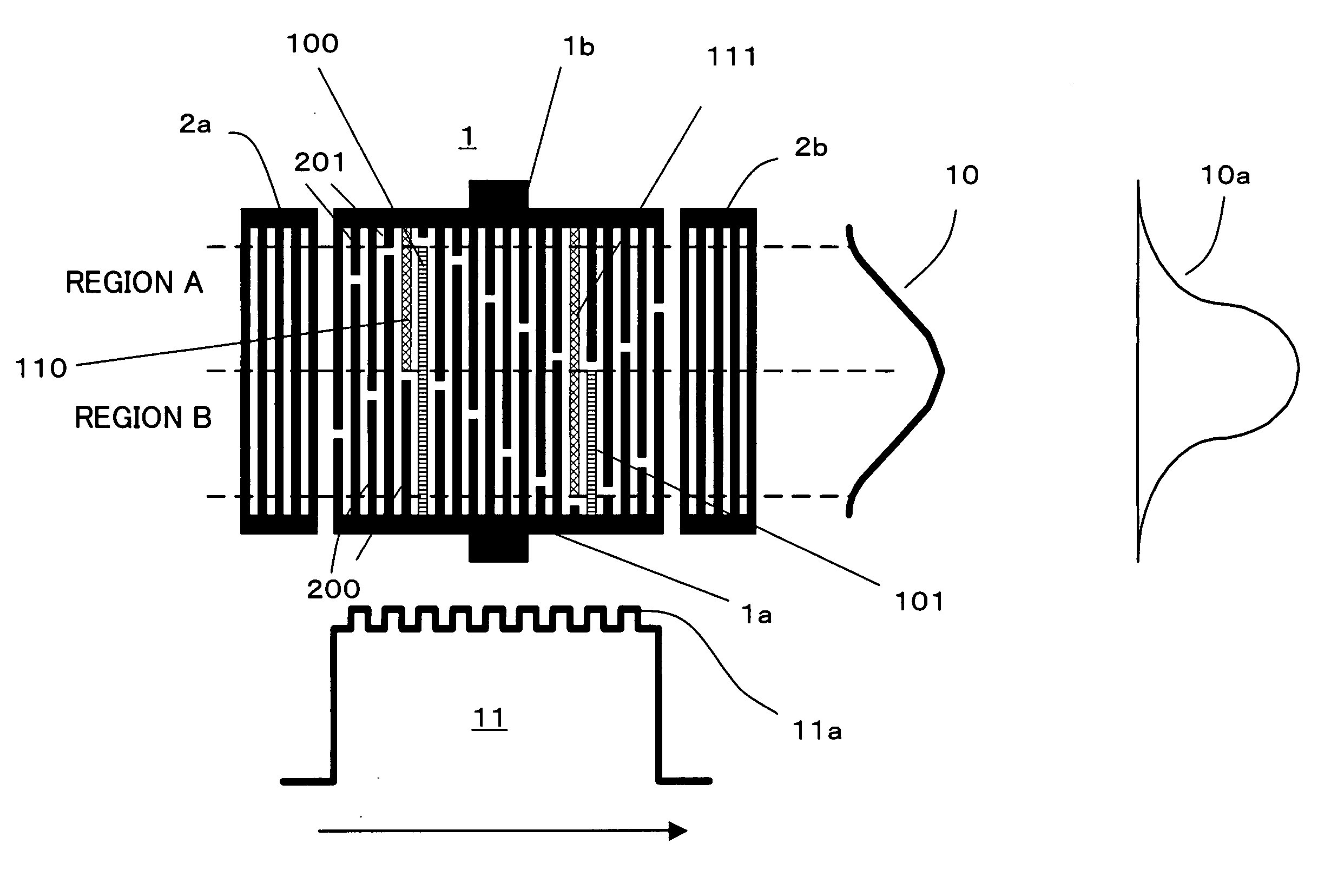

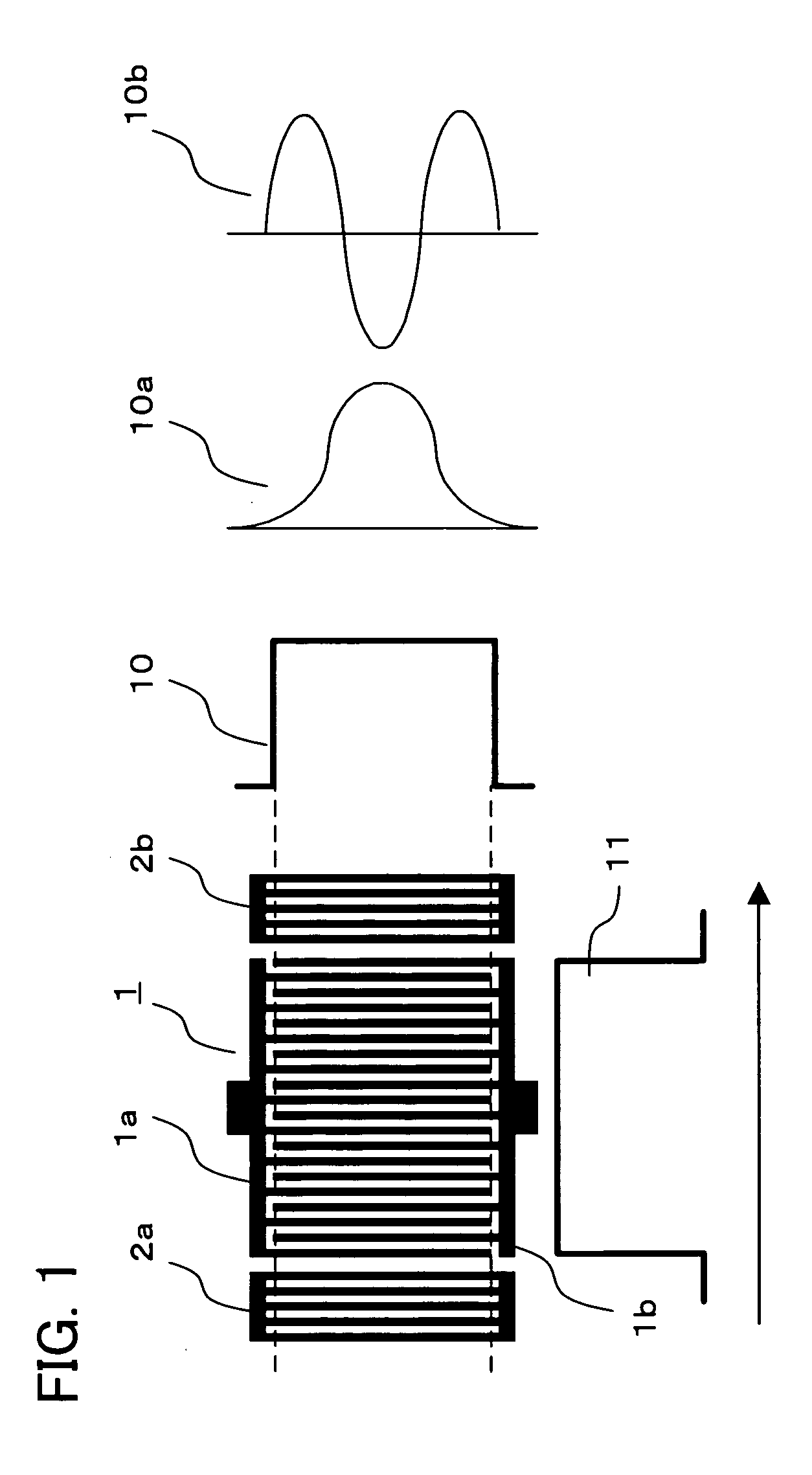

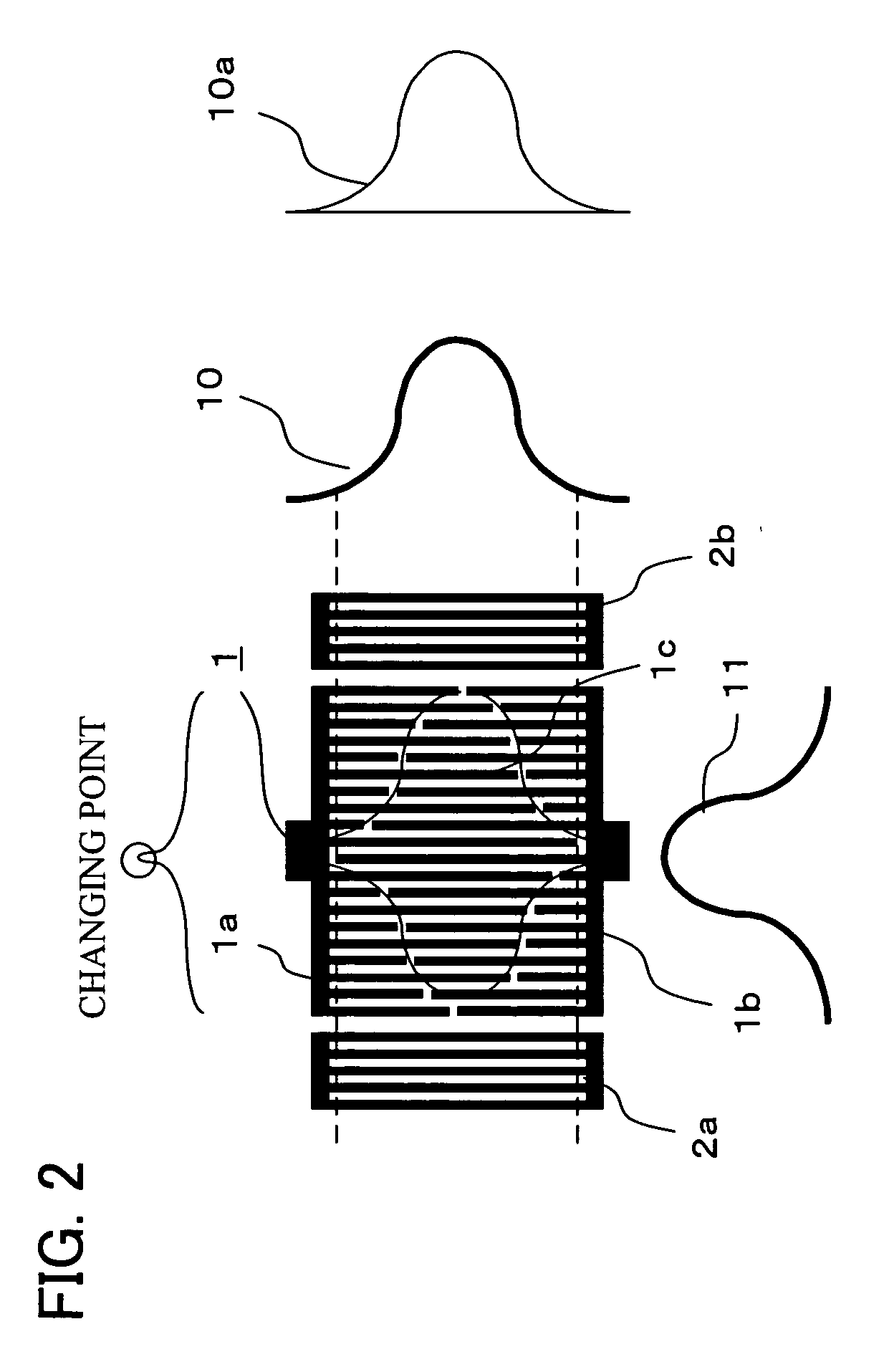

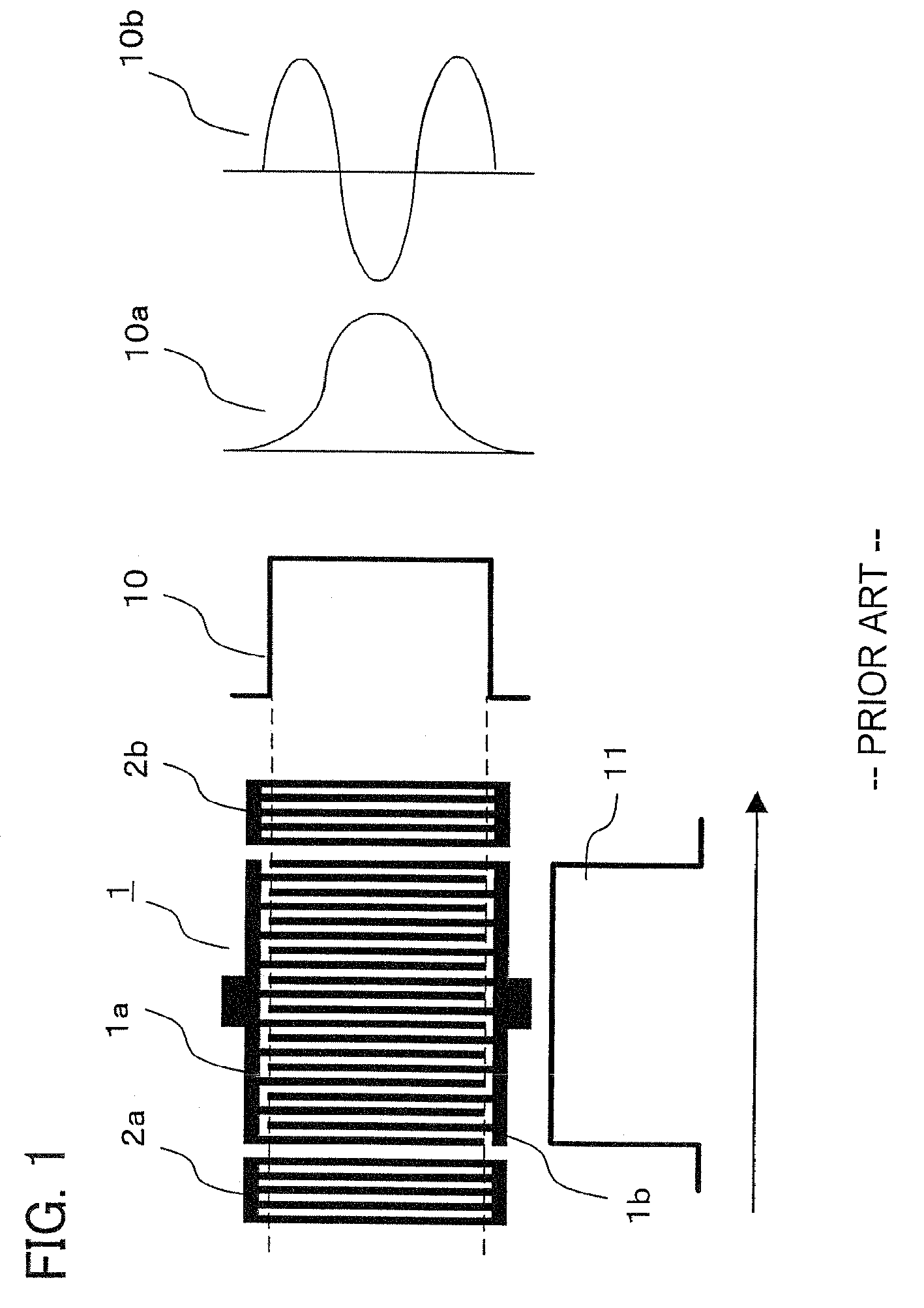

One-port surface acoustic wave resonator and surface acoustic wave filter

InactiveUS20060131992A1High frequencyReduce frequency fluctuationPiezoelectric/electrostriction/magnetostriction machinesImpedence networksTransducerAcoustic wave

A one-port surface acoustic wave resonator includes a rotated Y-cut LiTaO3 substrate, an interdigital electrode transducer disposed on the LiTaO3 substrate, and reflectors disposed on both sides of the interdigital electrode transducer in the surface acoustic wave propagation direction of the interdigital electrode transducer. When the electrode finger width of the interdigital electrode transducer is denoted by a and the gap between the electrode fingers is denoted by b, the metallization ratio, a / (a+b), is in the range of about 0.55 to about 0.85 and the interdigital electrode transducer is overlapping-length weighted.

Owner:MURATA MFG CO LTD

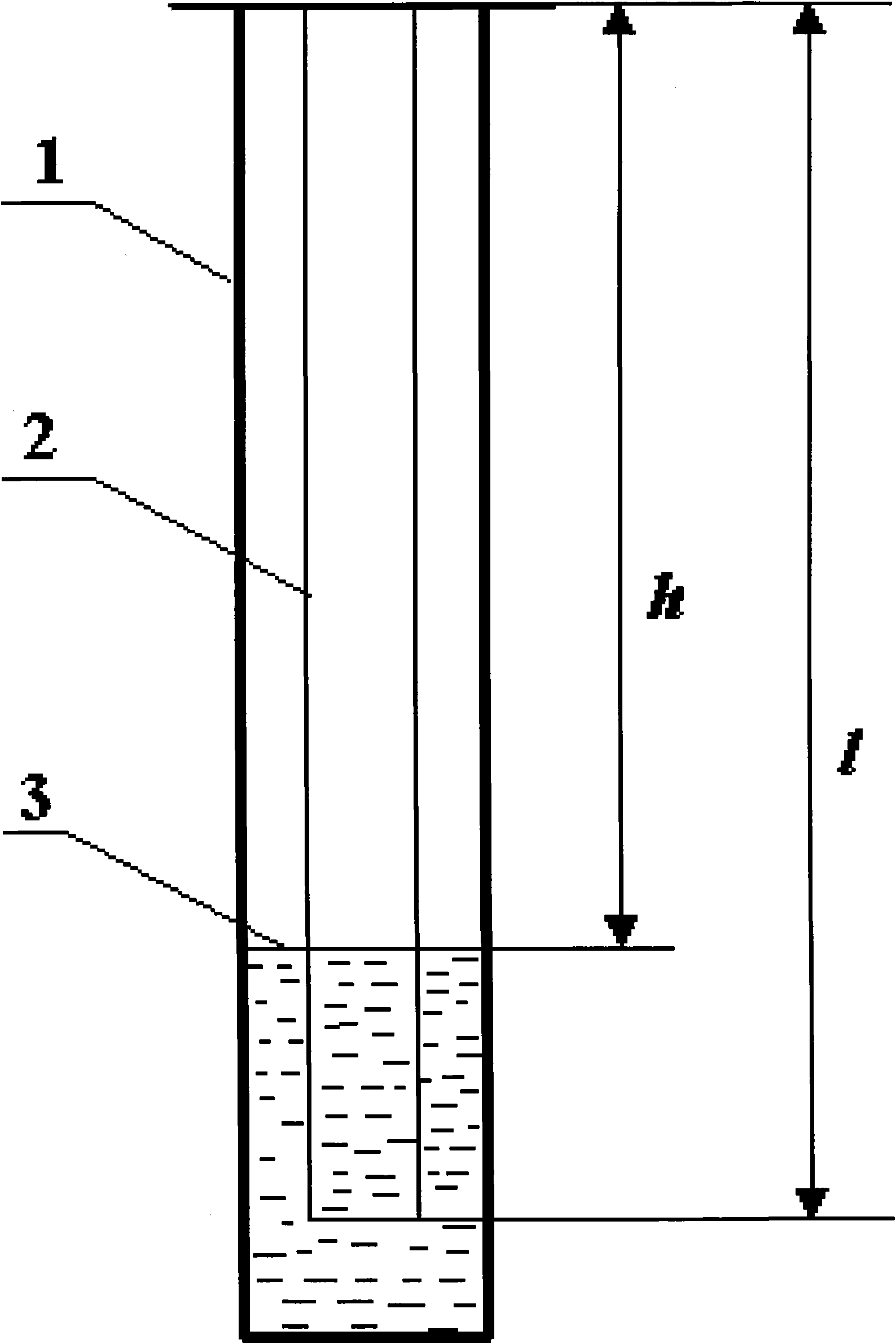

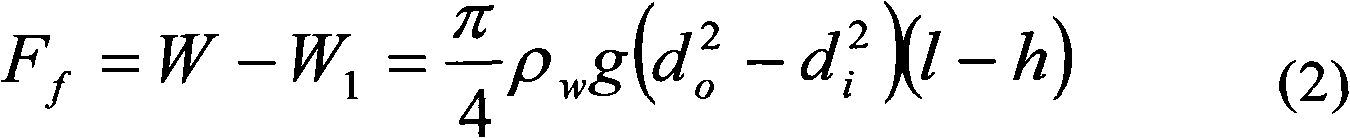

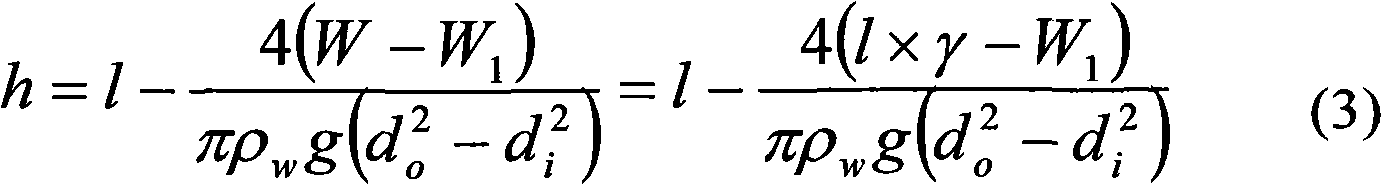

Weighing method for determining liquid level in wellbore of gas well

The invention relates to a weighing method for determining the liquid level in the wellbore of a gas well, which is applied to the technical field of gas production in oil fields. Firstly, the length l of a tubing string going down into the gas well, the average unit length weight Gamma of the tubing string, the outer diameter do of the tubing, the inner diameter di of the tubing and the density Rho of accumulated liquid are acquired; secondly, the weighing method is utilized to weigh the weight W1 of the tubing string in the liquid at the wellhead; finally, the length l of the tubing string, the average unit length weight Gamma of the tubing string, the outer diameter do of the tubing, the inner diameter di of the tubing, the density Rho of the accumulated liquid and the weight W1 of the tubing string in the liquid are put into a formula; and after calculation, the distance h between the level of the accumulated liquid in the gas well and the wellhead is obtained. The invention is characterized in that the liquid level in the wellbore can be determined as long as the weight of the tubing string is measured at the wellhead of the gas well. Since only the weight of the tubing string in the liquid is measured at the wellhead and a testing instrument does not need to be put down into the well bottom, compared with the prior art, the method has the advantages of easy testing and more accurate result.

Owner:PETROCHINA CO LTD

Surface enhanced pulp fibers in fiber cement

ActiveUS20170226009A1Wide applicabilityGood processing characteristicsSolid waste managementCement compositesPresent method

The present invention relates to a method of making a fiber-reinforced cementitious composite material which finds widespread applicability in a variety of construction and related applications. The composite comprises cellulosic fibrous material in order to provide the composite with the desired performance characteristics. Notably, at least a portion of the cellulosic fibrous material comprises surfaced enhanced pulp fiber, which desirably enhances the processing characteristics of the material, as well enhancing the characteristics of the finished composite product. The method of making a fiber-reinforced cementitious composite comprising the steps of providing a cementitious composition, and providing cellulosic fibrous material. The present method further includes blending the cementitious composition and the cellulosic fibrous material to form the cementitious composite. The surface enhanced pulp fiber preferably comprises approximately 1-10%, by weight, of the cellulosic fibrous material, and the cellulosic fibrous material exhibits an enhanced Bauer-McNett long fiber fraction. The cellulosic fibrous material preferably exhibits at least a 10% increase in length-weighted average fiber length (LWAFL), in comparison to a cellulosic fibrous material which is devoid of surface enhanced pulp fiber. The cellulosic fibrous material requires relatively reduced refining energy, in comparison to a cellulosic fibrous material which is devoid of surface enhanced pulp fiber, to reach a predetermined freeness CSF (Canadian Standard Freeness) value.

Owner:DOMTAR PAPER COMPANY

Cellulose fibre composition

Owner:ZEO IP

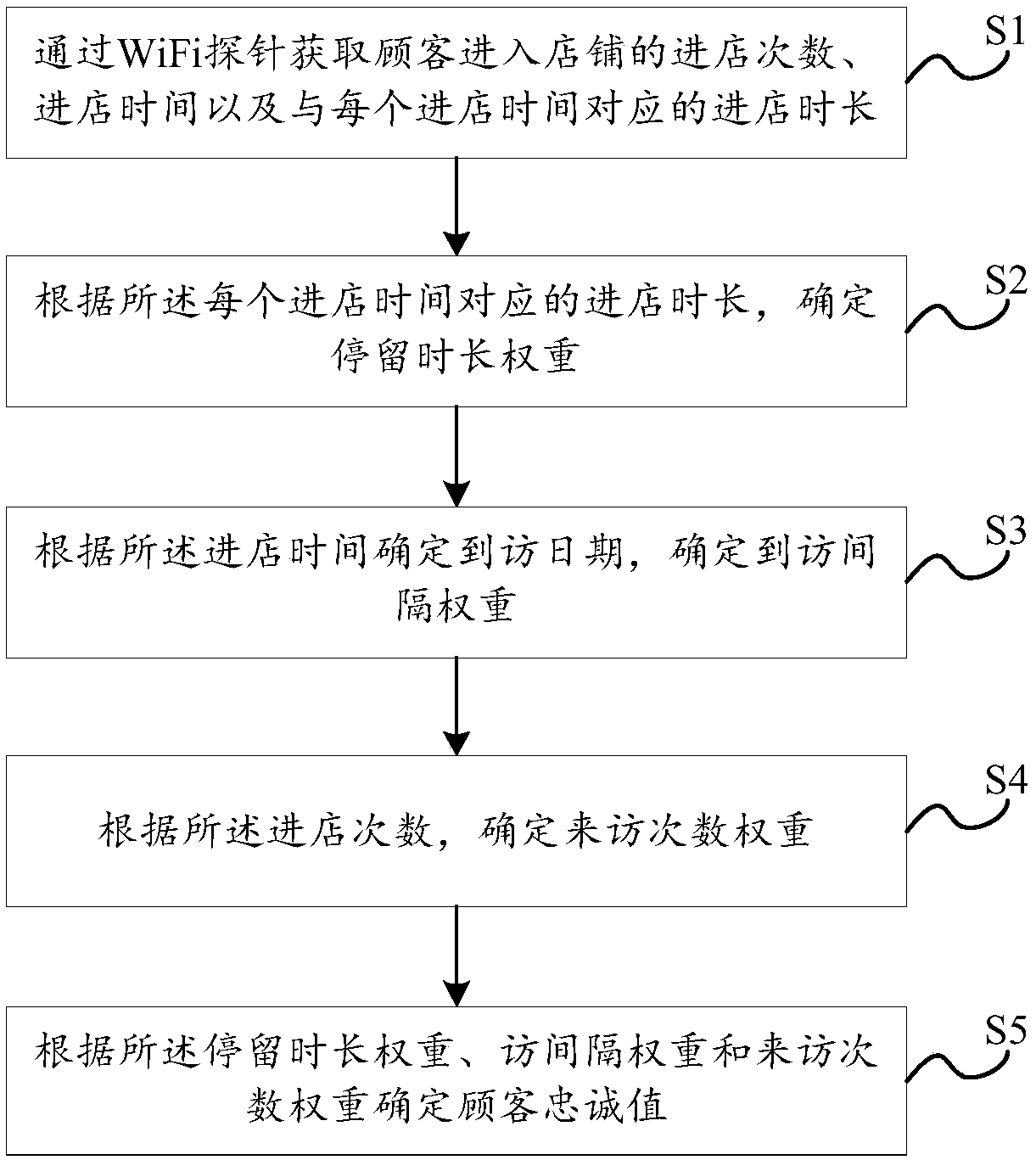

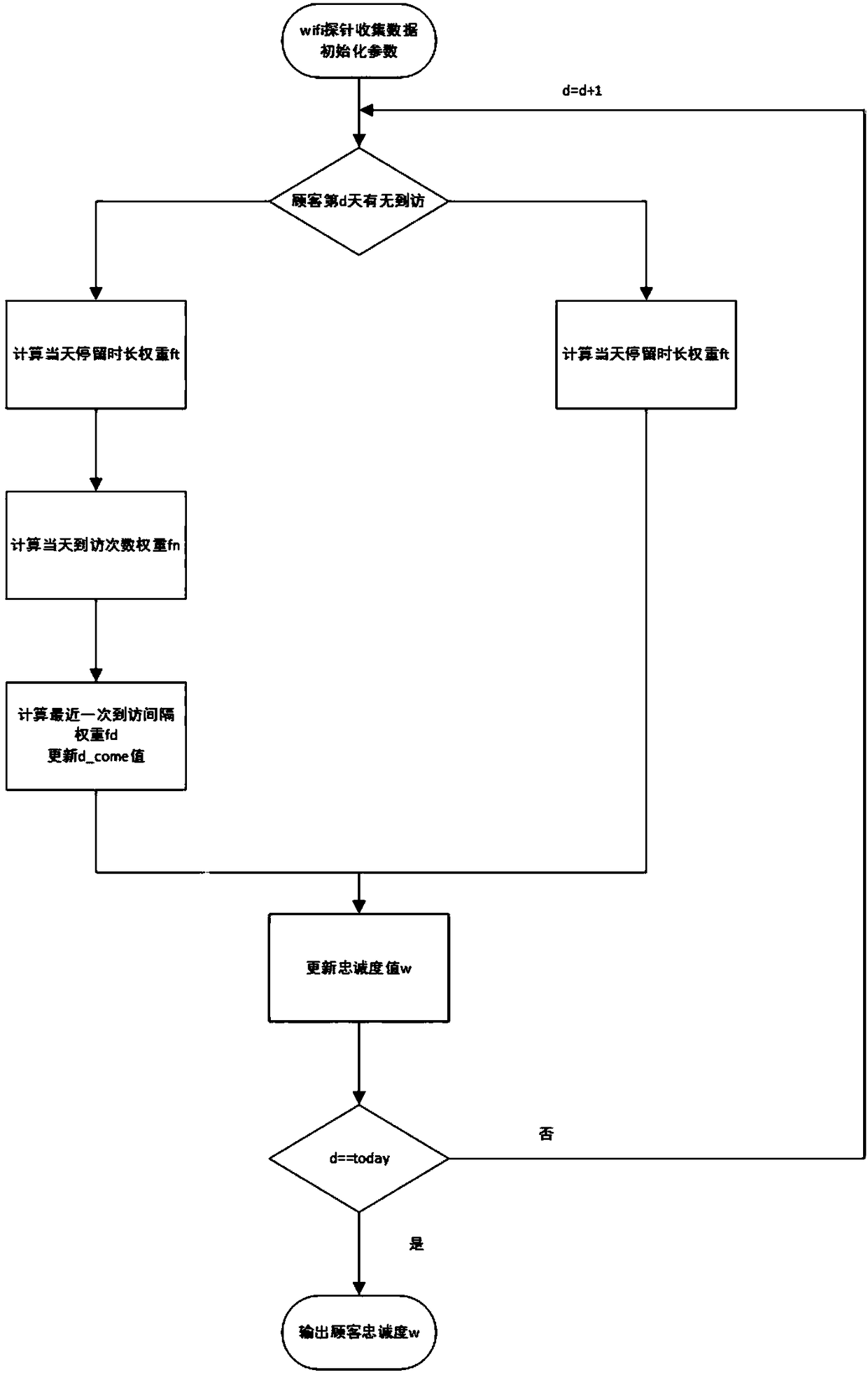

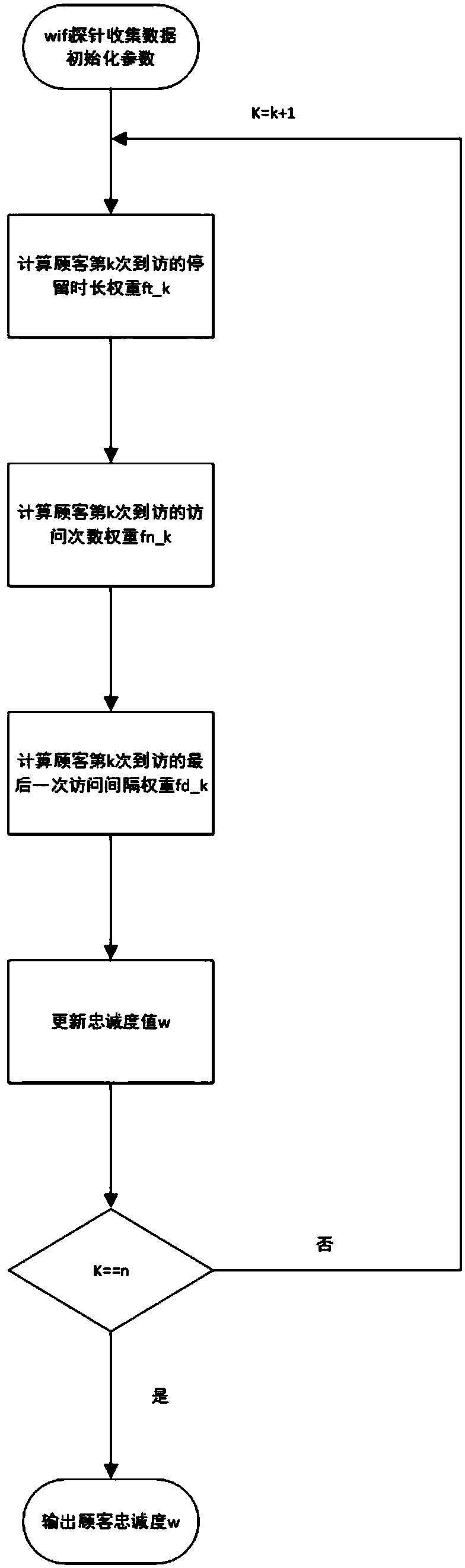

Customer loyalty processing method and device

ActiveCN108389060ASolve the technical problem of loyalty value calculationCustomer relationshipMarket data gatheringLength weightComputer science

The invention discloses a customer loyalty processing method and device. A WiFi probe obtains shop entering frequency, shop entering time and shop entering time length corresponding to each shop entering time of a customer; a staying time length weight ft is obtained according to the shop entering time length corresponding to each shop entering time; a visit date is determined according to the shop entering time, and a visit interval weight fd is determined; a visit frequency weight fn is determined according to the shop entering frequency; and a customer loyalty w is determined according to the staying time length weight ft, the visit interval weight fd and the visit frequency weight fn. Thus, the customer loyalty is determined, the loyalty can be determined if the customer is not loggedin by a system or is a non-registered member, and the technical problem that only the loyalty of the customer who is registered or logged in by the CRM system can be calculated in the related art is solved.

Owner:NANJING ZHIMA INFORMATION TECH

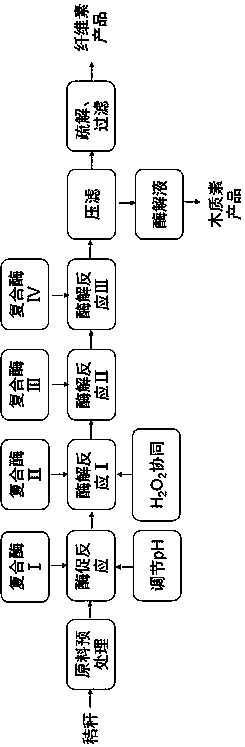

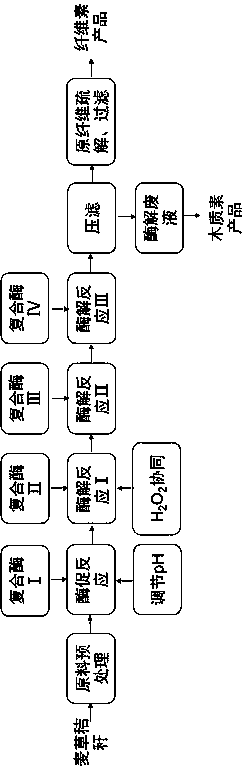

Straw fiber and process for separating straw fiber by bio-enzyme method

InactiveCN108286200AImprove fiber qualityQuality improvementCellulose treatment using microorganisms/enzymesNon-woody plant/crop pulpCelluloseBlack liquor

The invention belongs to the field of biological pulping and provides straw cellulose. The straw cellulose is characterized in that straw stalk fiber cut and separated by enzyme molecules directionally is well preserved, the result that fine fiber is damaged in the traditional chemical pulping is overcome, the length-weight average value is 0.70 to 1.10 mm, and the quality-weight average value is1.10 to 1.40 mm. The invention further provides straw fiber. The straw fiber comprises the fiber structure of the straw cellulose; the quality of the straw stalk fiber is as follows: the brightness (whiteness) is 57 to 75 percent, the hardness is 7 to 26 K, the folding resistance is 30 to 78 times, the tearing index is 3.0 to 5.5 mN.m<2> / g, and the tensile index is 41.0 to 62.0 N.m / g. The invention further provides a process for separating fiber from straws and application of the straw fiber. High-temperature chemical cooking black liquid is not generated in the production process, the fiber quality (length, whiteness, short fiber content and the like) is obviously more excellent than the quality of the traditional chemical pulping, the pulp yield is increased by 25 percent or higher whenbeing compared with that of the traditional chemical pulping rate, and water consumption and energy consumption in the production process are reduced by 30 percent or higher when being compared with those of the traditional chemical pulping.

Owner:QILU UNIV OF TECH

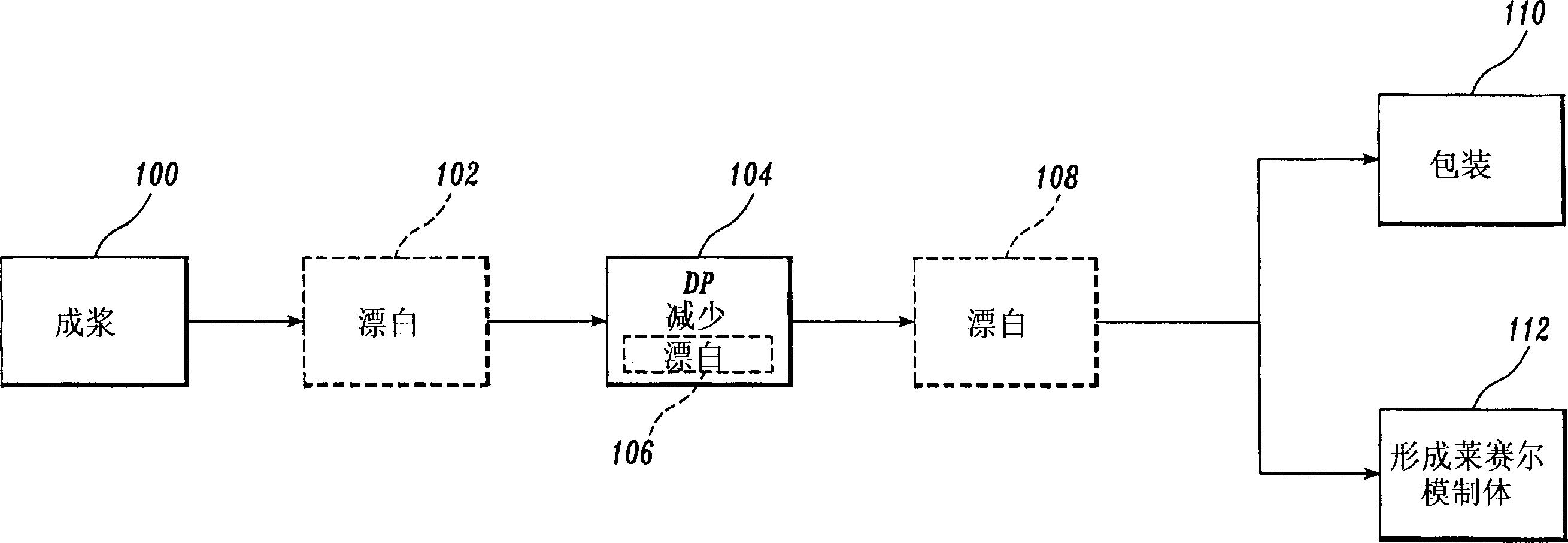

Sawdust alkaline pulp having low average degree of polymerization values and method of producing the same

InactiveCN1505703APulp properties modificationMonocomponent cellulose artificial filamentFiberLength weight

The present invention provides compositions, useful for making lyocell fibers, having a high hemicellulose content, a low copper number and including cellulose that has a low average degree of polymerization (D.P.), wherein greater than 4% of pulp fibers have a length-weighted fiber length of less than 2.0 mm. Further, the present invention provides processes for making compositions, useful for making lyocell fibers, having a high hemicellulose content, a low copper number and including cellulose that has a low average degree of polymerization and short fibers. The present invention also provides lyocell fibers and molded bodies made from the compositions. An advantage of the compositions are their quick dissolving nature.

Owner:WEYERHAEUSER CO

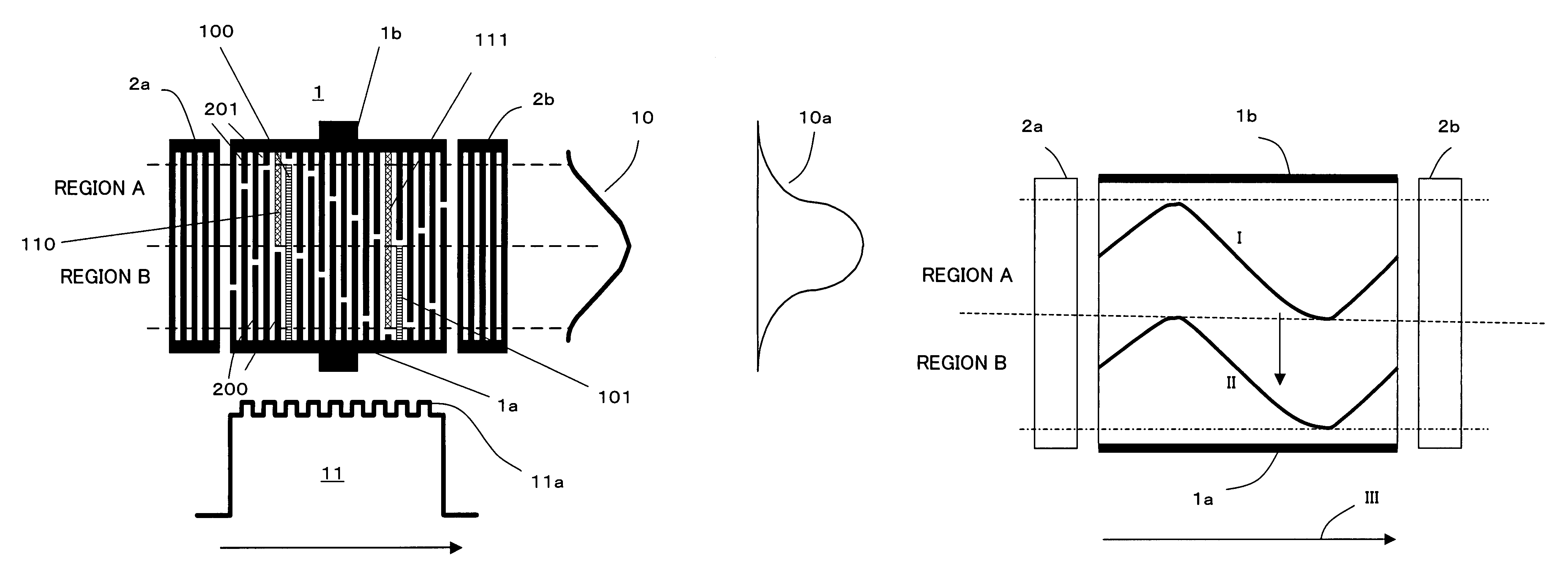

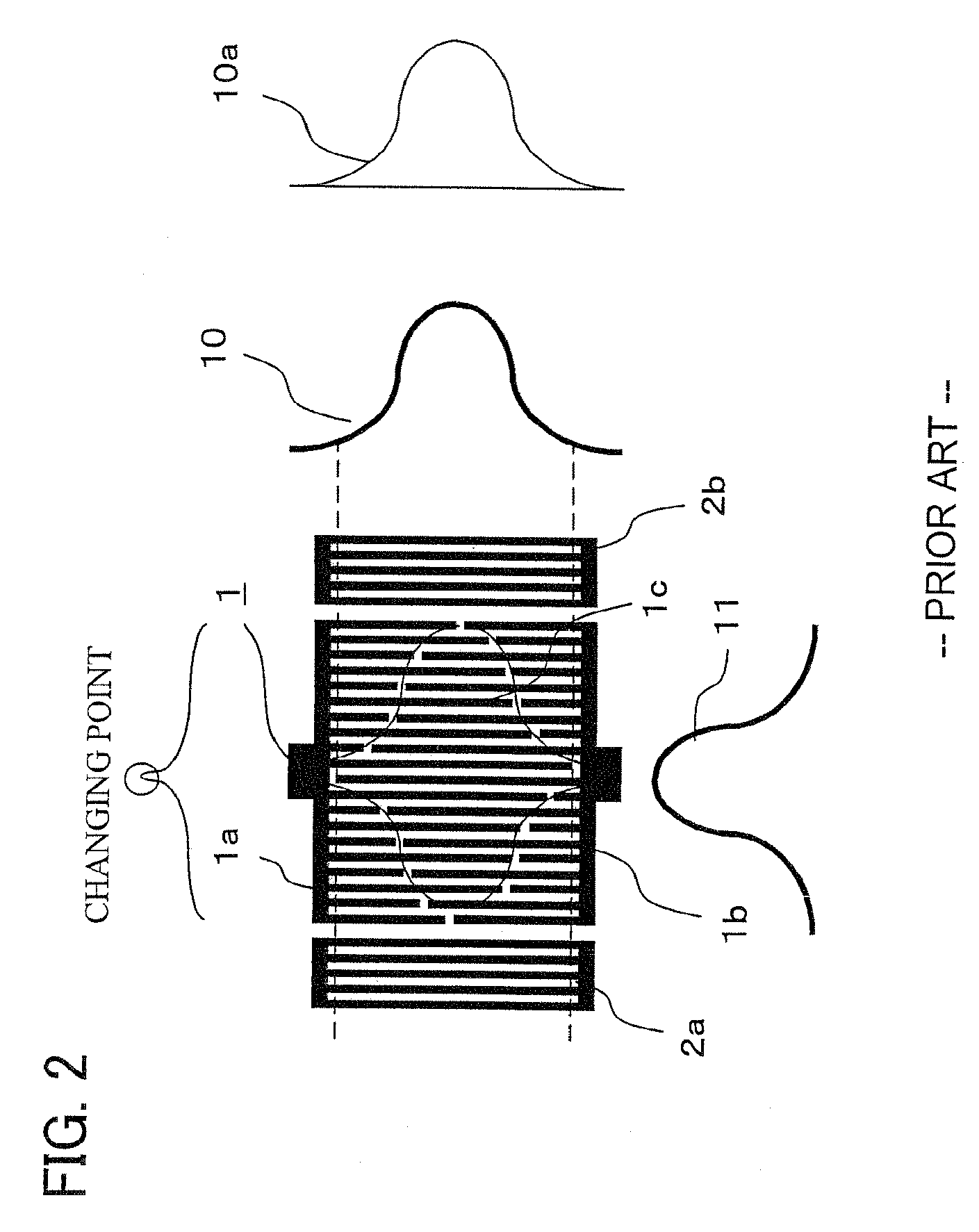

Surface acoustic wave apparatus

A surface acoustic wave apparatus has a configuration by which the spurious of the higher-order transverse modes is suppressed and a SAW excitation intensity distribution is not changed in the propagation direction. The surface acoustic wave apparatus has at least one interdigital transducer; a region with the plurality of interleaved comb-shaped electrodes is formed with two regions which are a first overlapping region and a second overlapping region with overlapping-lengths weighted along a propagation direction of a surface acoustic wave; the first overlapping region and the second overlapping region are in contact or overlapped in a direction vertical to the propagation direction of the surface acoustic wave; and in either the first or the second overlapping region, an overlapping-length weighting envelope curve has at least two or more changing points in the propagation direction of the surface acoustic wave.

Owner:TAIYO YUDEN KK

Wheat straw fibers and technology for separating films by biological enzyme method thereof

InactiveCN108286201AImprove fiber qualityQuality improvementCellulose treatment using microorganisms/enzymesNon-woody plant/crop pulpCelluloseBiotechnology

The invention belongs to the field of bio-pulping, provides wheat straw cellulose, and aims at storing straw fibers which are subjected to directional cutting and separating by enzyme molecules and overcoming the result of damage to fine fibers in traditional chemical pulping. The wheat straw cellulose is 0.80-1.10mm in average length based on length-weight ratio and is 1.20-1.50mm in average length based on mass-weight. The invention also provides wheat straw fibers comprising the fiber structure of the abovementioned wheat straw cellulose. The quality of the wheat straw fibers meets that thebrightness (whiteness) is 53-75%; the hardness is 8-26K; the folding strength is 30-75 times; the tearing index is 3.3-5.5mN.m<2> / g; and the tensile index is 45.0-62.0N.m / g. The invention also provides a wheat straw fiber separating technology and application of the wheat straw fibers. According to the technology, high-temperature chemical boiling black liquid is not produced in the production process; the fiber quality (length, whiteness, short fiber content, etc.) is obviously superior to that of traditional chemical pulping fibers; the pulp yield is increased by more than 25% by being compared with traditional chemical pulping yield; the water consumption and the energy consumption in production are decreased by more than 30% by being compared with those in traditional chemical pulping.

Owner:QILU UNIV OF TECH

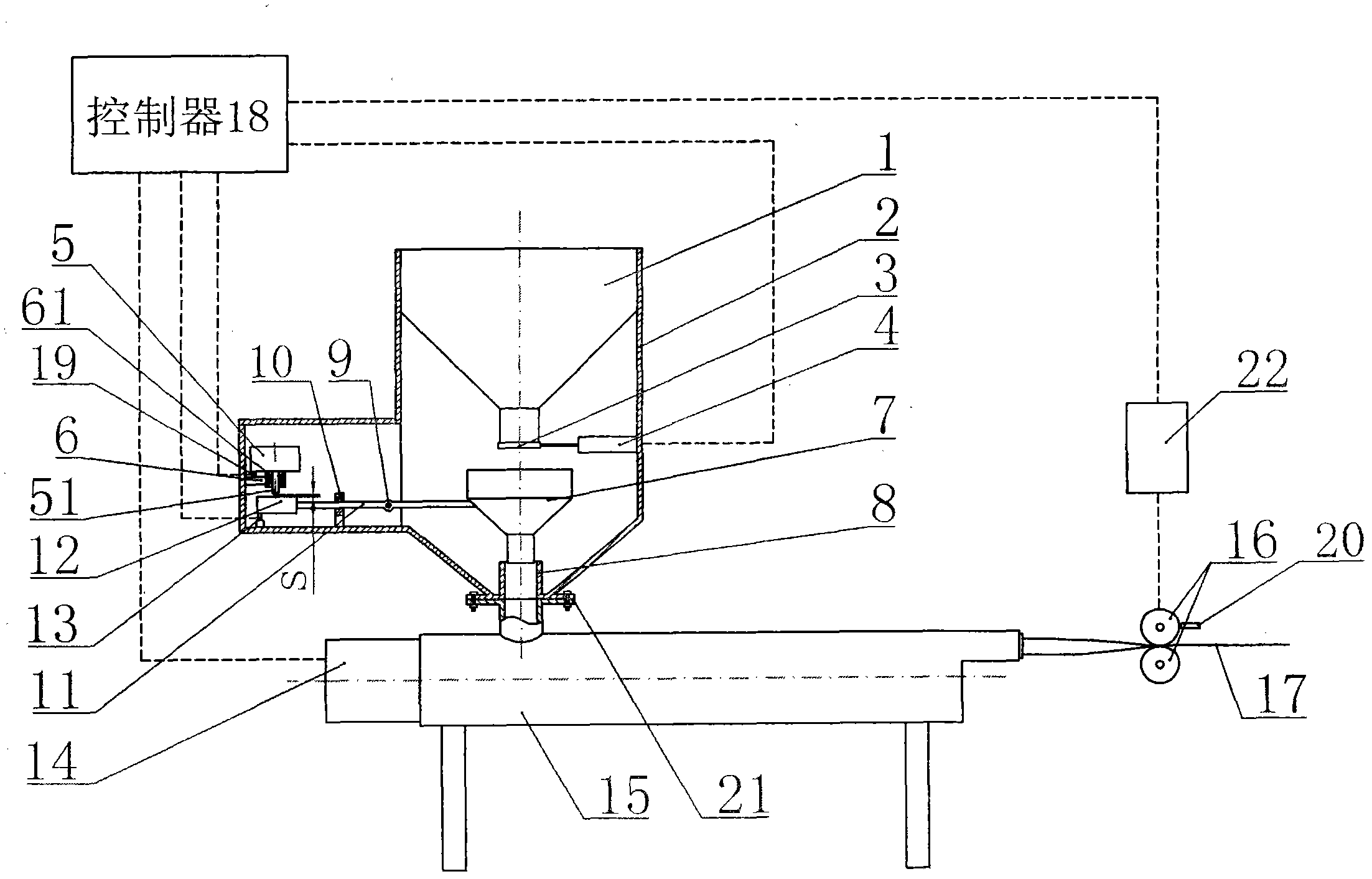

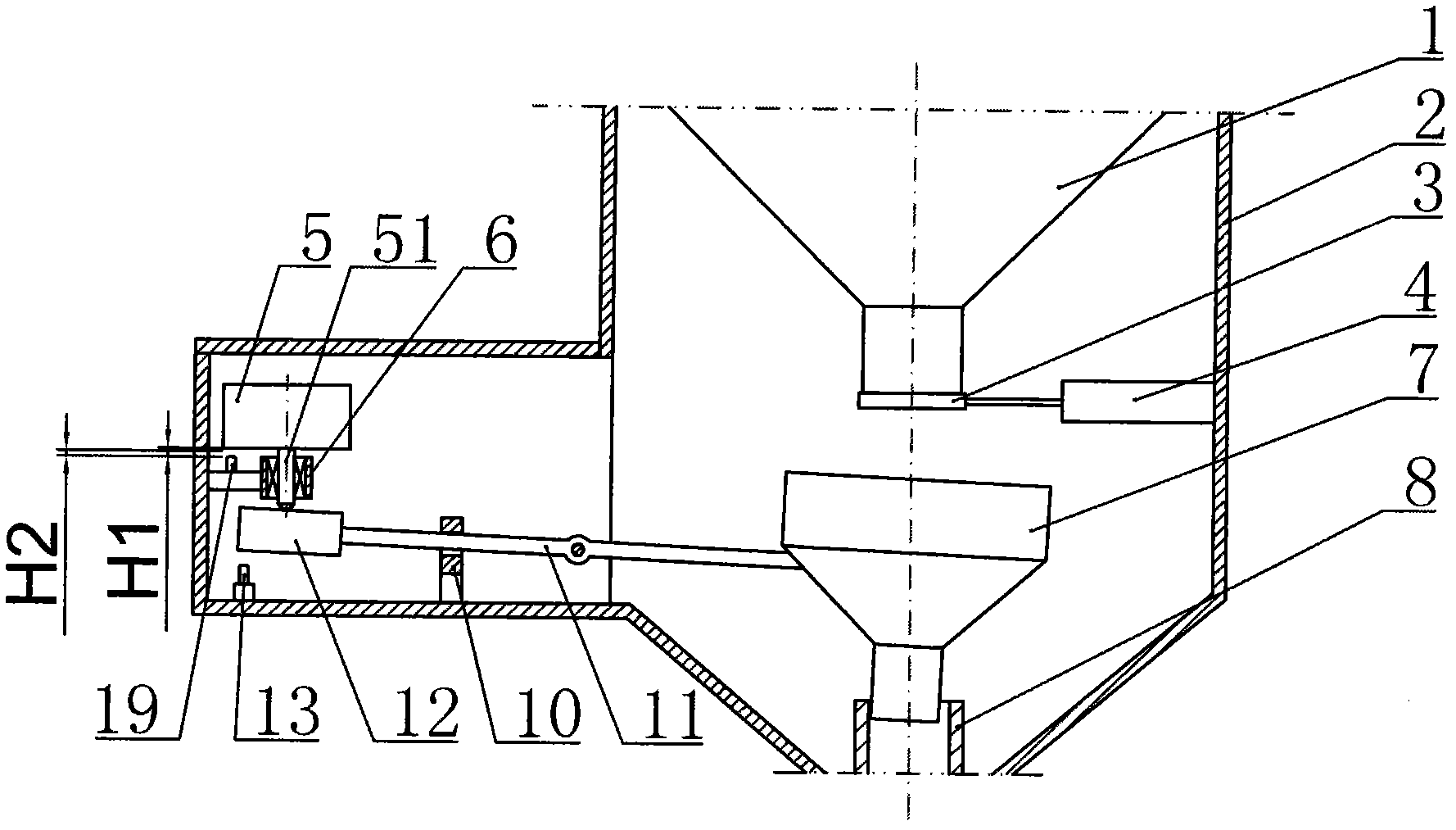

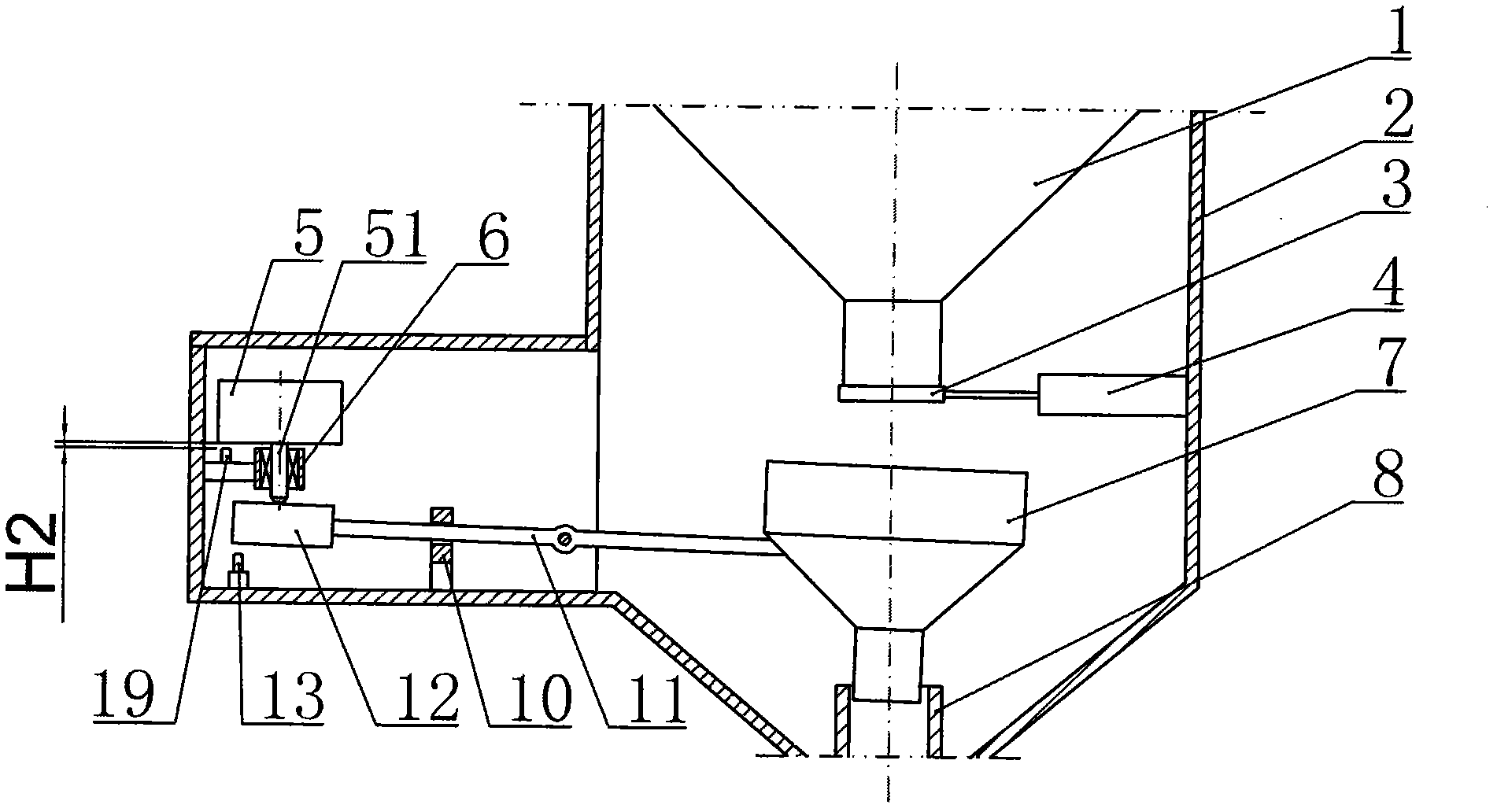

High-precision automatic control device for extruder output weight per unit length

A high-precision automatic control device for the weight per unit length of extruder output. The input end of the controller is connected to the weighing device, and the output end of the controller is connected to the drive motor of the extrusion screw of the extruder or the drive of the traction roller. motor connection. The weighing device includes a raw material hopper, a frame and a weighing hopper. The raw material hopper is installed on the upper end of the frame, and a gate is installed at the outlet of the lower end of the raw material hopper; the weighing hopper is installed under the raw material hopper, and one side of the weighing hopper is connected to the One end of a lever is connected, and the other end of the lever is equipped with a fixed counterweight. The fulcrum of the lever is hinged on the frame, and a lower proximity switch is installed under the fixed counterweight; The movable counterweight is vertically slidably supported on a counterweight bracket, and an upper proximity switch is arranged below the movable counterweight; the gate, the upper proximity switch and the lower proximity switch are connected to the controller respectively. The advantages are: the structure is simplified, the cost is reduced, the control principle is simple, and the control precision is improved.

Owner:王根乐

Separator for electrochemical element and electrochemical element

ActiveUS20180274174A1Excellent characteristicsGood densenessHybrid capacitor separatorsSpecial paperLength weightCellulose fiber

Provided is a separator for an electrochemical element, the separator having improved tensile strength and short-circuit resistance while maintaining the impedance characteristics and denseness expected of a separator comprising highly beaten regenerated cellulose fibers. The separator for an electrochemical element is interposed between a pair of electrodes and capable of holding an electrolytic solution containing an electrolyte, the separator for an electrochemical element comprising: 20 to 80 mass % of natural cellulose fibers A in which the length weighted average fiber length is 0.30 to 1.19 mm and the CSF is 500 to 50 ml; 10 to 50 mass % of natural cellulose fibers B in which the length weighted average fiber length and the maximum distribution fiber length are 1.20 to 1.99 mm and the CSF is 500 to 50 ml; and 10 to 50 mass % of beaten regenerated cellulose fibers.

Owner:NIPPON KODOSHI

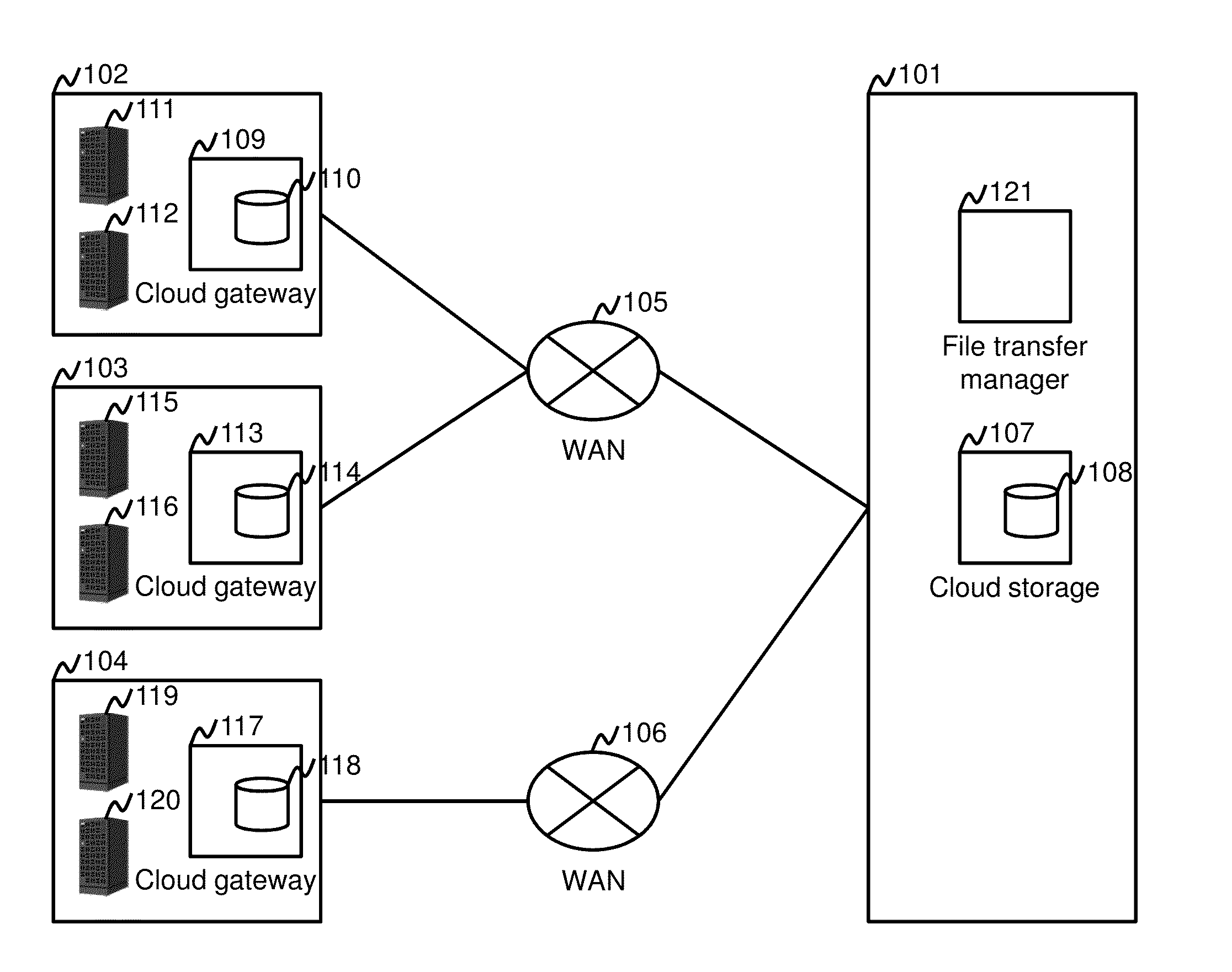

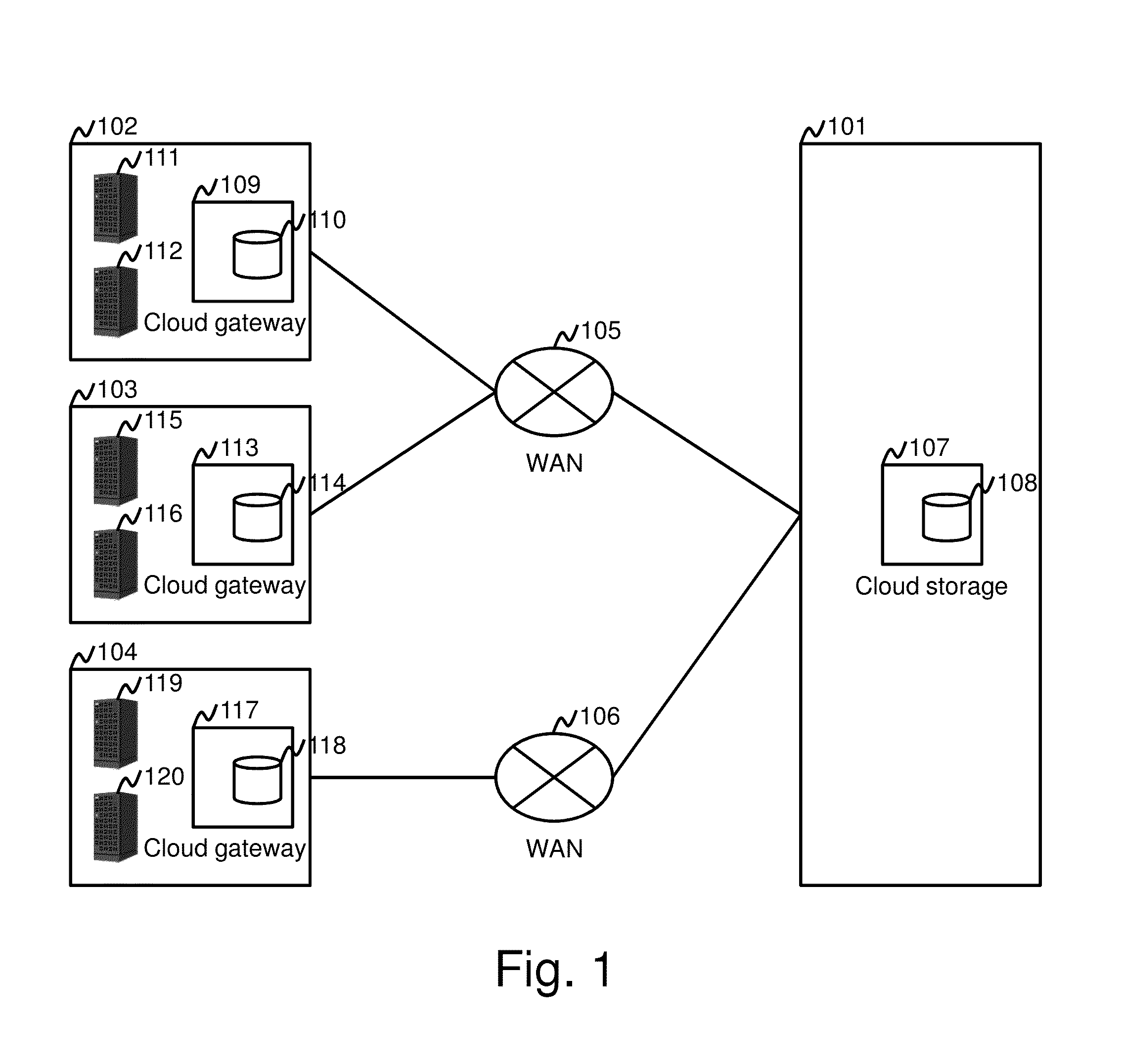

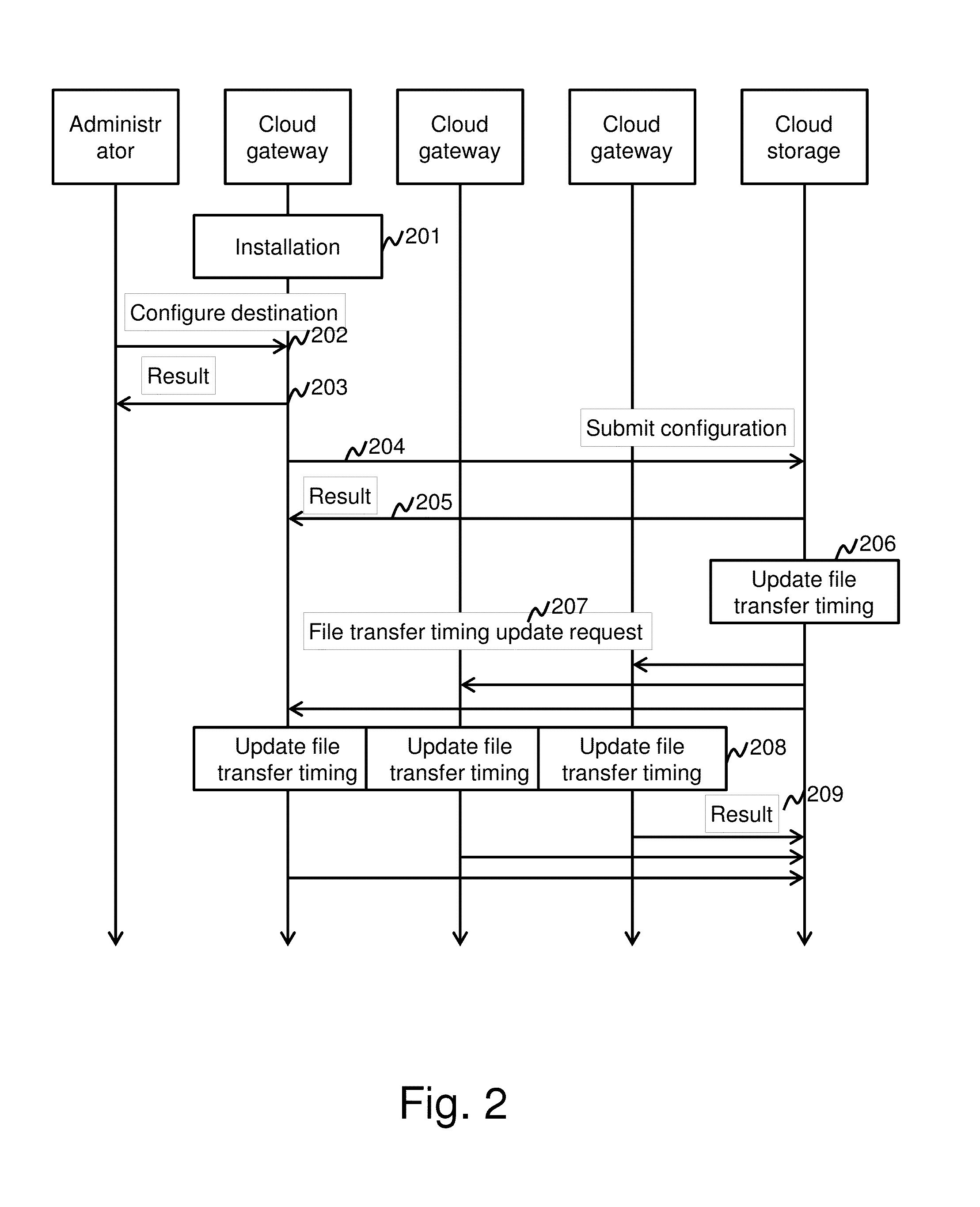

Method and apparatus to transfer file data to a cloud environment

ActiveUS20140195572A1Digital data information retrievalSpecial data processing applicationsTraffic capacityLength weight

Systems and methods are directed to a file storage system that manages configuration information for each cloud gateway's storage device. Systems and methods also manage a configuration parameter; and a file transfer slot number, which represents how many HTTP sessions the cloud gateway can process substantially simultaneously. Based on the configuration information, systems and methods may prioritize the multiple cloud gateways. Systems and methods calculate time lengths weighted by the priorities of the cloud gateways and multiplied by the file-transfer slot number for each cloud gateway in a time period, and then allocate time slots of the cloud gateways in the time period according to the above calculated time lengths. Systems and methods therefore allow for automatically aligning the traffic between cloud gateways and cloud storage according to the configuration of cloud gateways.

Owner:HITACHI LTD

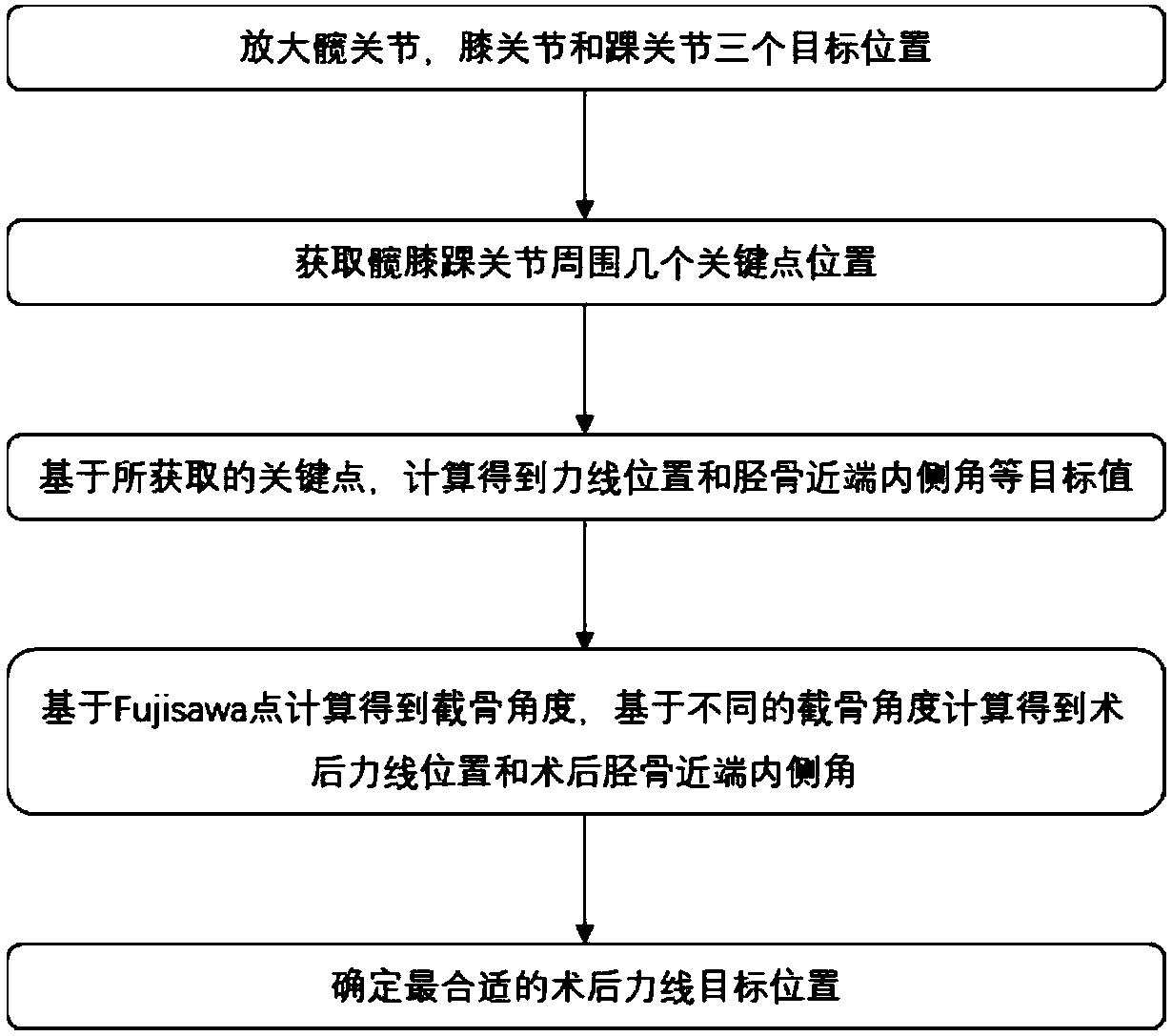

System, computer readable storage medium and apparatus that can be used for two-dimensional planning of high tibial osteotomy

The present invention relates to the field of clinical medicine, and in particular to a system, a computer readable storage medium and an apparatus that can be used for two-dimensional planning of high tibial osteotomy. The present invention provides a computer readable storage medium storing a computer program, the computer program is executable to implement method steps, and the method steps comprise: acquiring a lower-limb full-length weight-bearing-position bone fluoroscopic image; acquiring a force line position; acquiring a lateral angle of the distal femur; acquiring a medial angle of the proximal tibia; acquiring an osteotomy angle [theta], and acquiring the position of the postoperative force line and / or the postoperative medial angle of the proximal tibia according to the osteotomy angle [theta]. The method provided by the invention can flexibly select the target position of the postoperative force line according to different lower limb conditions of different patients, so that the planning is more individualized.

Owner:影为医疗科技(上海)有限公司

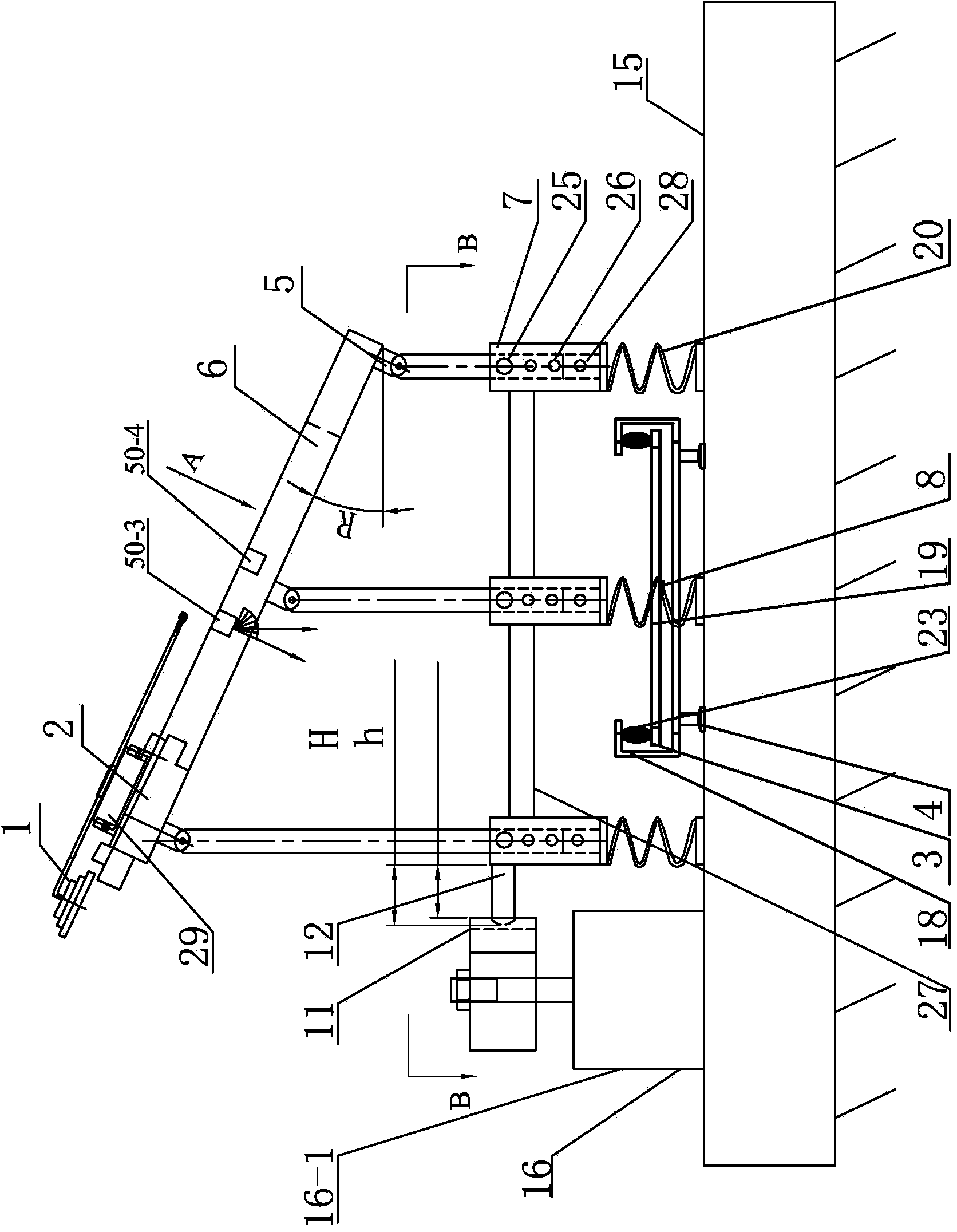

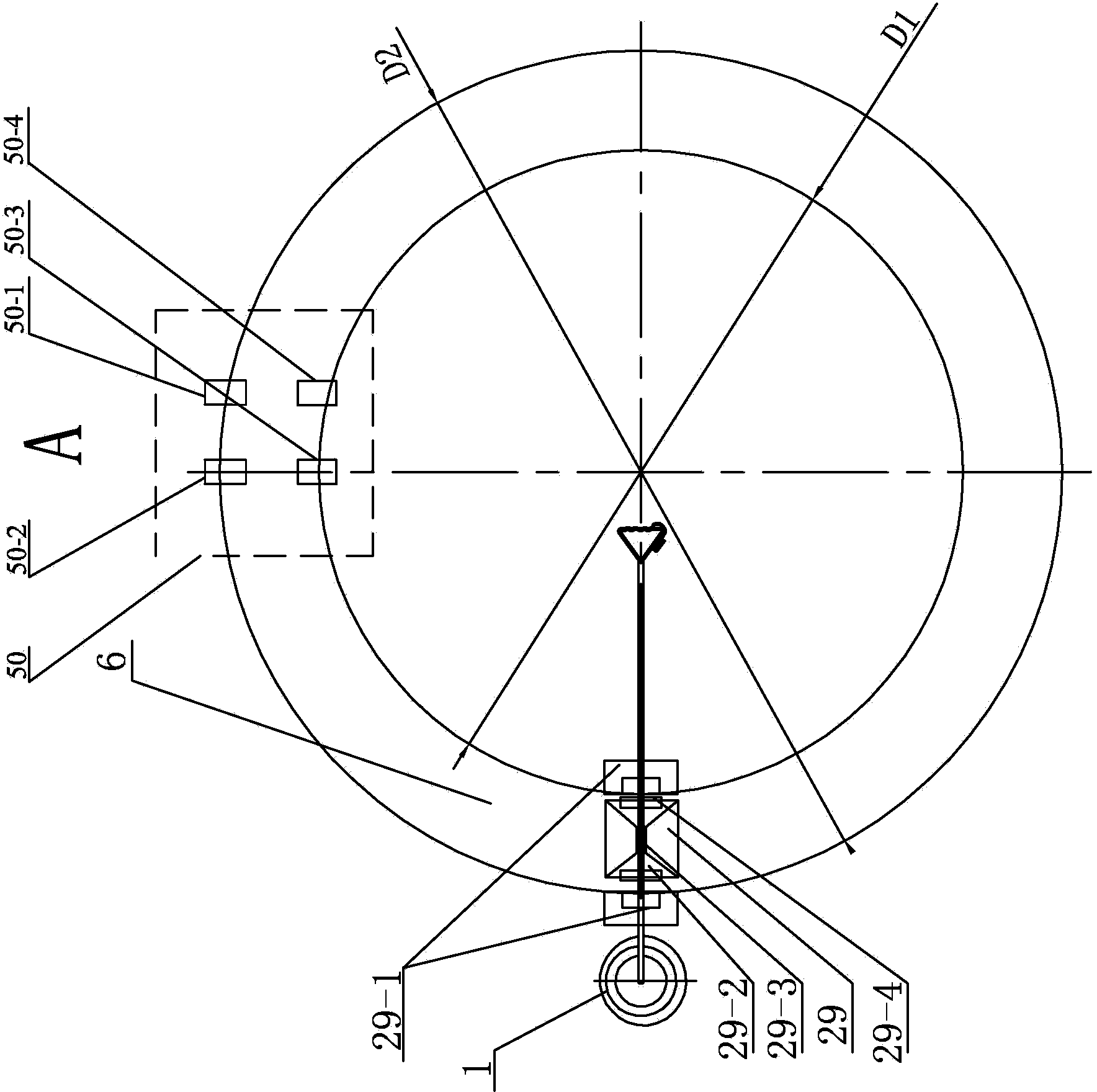

Laser-type super-equal-length weight throw core stable force training and information feedback device

InactiveCN103638657AAvoid instabilityAccurate postureMovement coordination devicesCardiovascular exercising devicesLength weightEngineering

The invention discloses a laser-type super-equal-length weight throw core stable force training and information feedback device and relates to super-equal-length weight throw training devices. The invention aims to solve the problems that a device for integrating weight throw final force core stable force training and information feedback into a whole does not exist in the prior art, a training device for integrating weight throw core force training and super-equal-length training into a whole does not exist in the prior art and the training speed during the weight throw final force cannot be measured. According to the technical scheme adopted for solving the technical problems, the device comprises a training handheld weight component, a swing bracket, a motor component, a fitting piece, a fixing plate, a balance training mechanism with an information feedback function, a moving mechanism, a laser speed sensor and a travel switch, wherein the swing bracket comprises an annular plate, a supporting leg and a first spring; the motor component comprises a motor and a cam; and the training handheld weight component comprises a connecting rod, a handle, a fixing block and a weight. The device is used for super-equal-length weight throw training.

Owner:HENAN INST OF SCI & TECH

Surface acoustic wave apparatus

InactiveUS7482896B2Suppress spursPiezoelectric/electrostriction/magnetostriction machinesImpedence networksLength weightTransverse mode

A surface acoustic wave apparatus has a configuration by which the spurious of the higher-order transverse modes is suppressed and a SAW excitation intensity distribution is not changed in the propagation direction. The surface acoustic wave apparatus has at least one interdigital transducer; a region with the plurality of interleaved comb-shaped electrodes is formed with two regions which are a first overlapping region and a second overlapping region with overlapping-lengths weighted along a propagation direction of a surface acoustic wave; the first overlapping region and the second overlapping region are in contact or overlapped in a direction vertical to the propagation direction of the surface acoustic wave; and in either the first or the second overlapping region, an overlapping-length weighting envelope curve has at least two or more changing points in the propagation direction of the surface acoustic wave.

Owner:TAIYO YUDEN KK

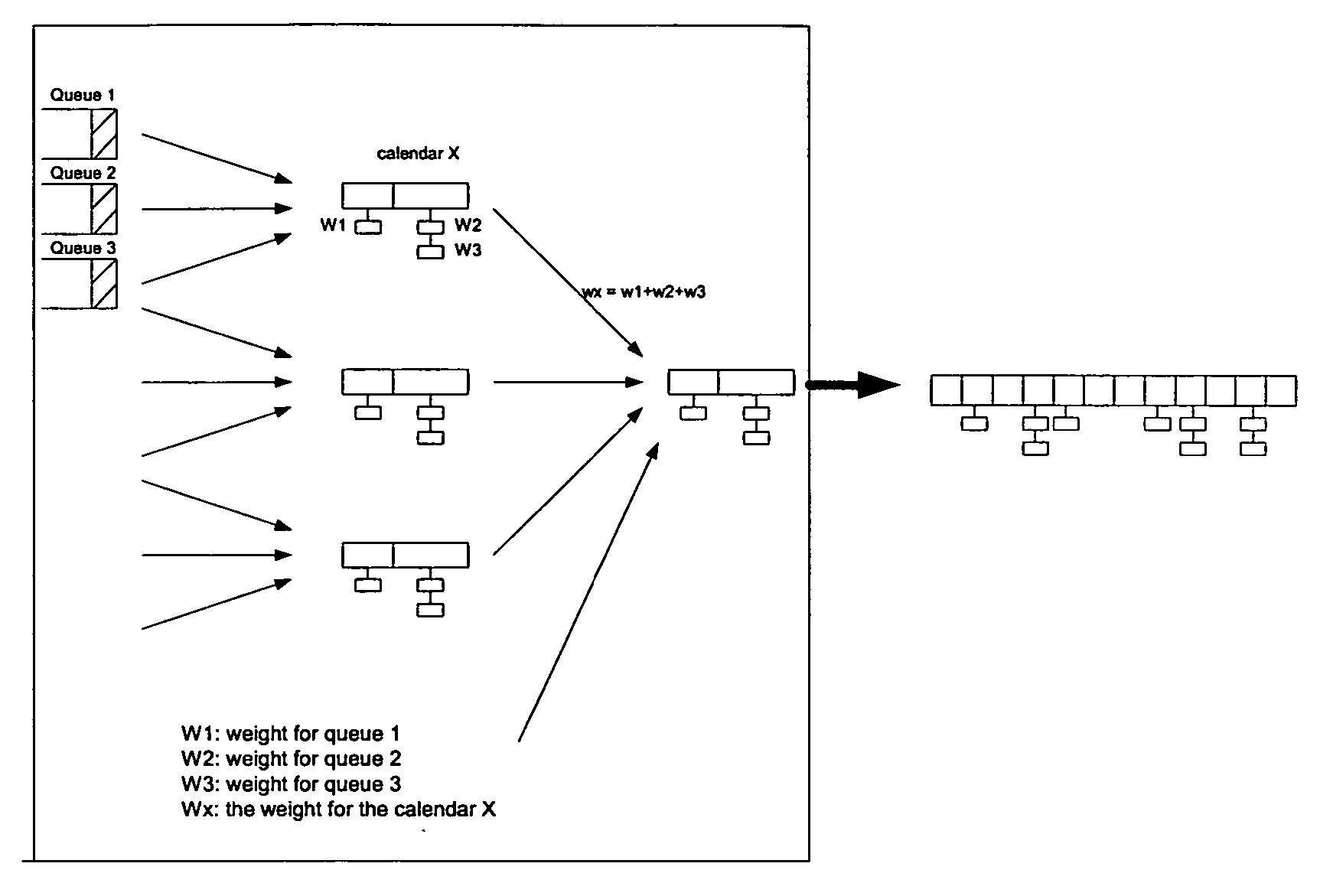

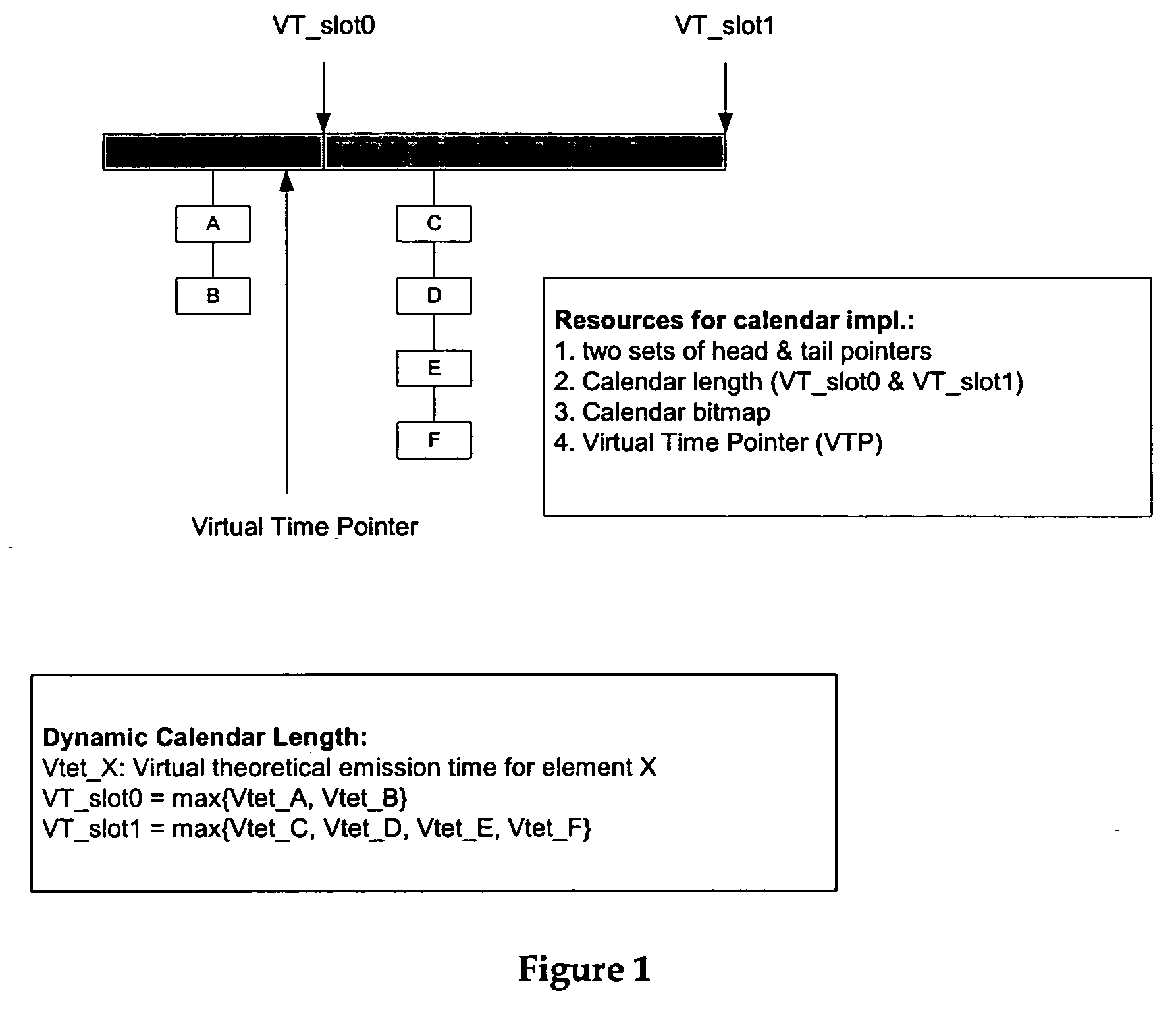

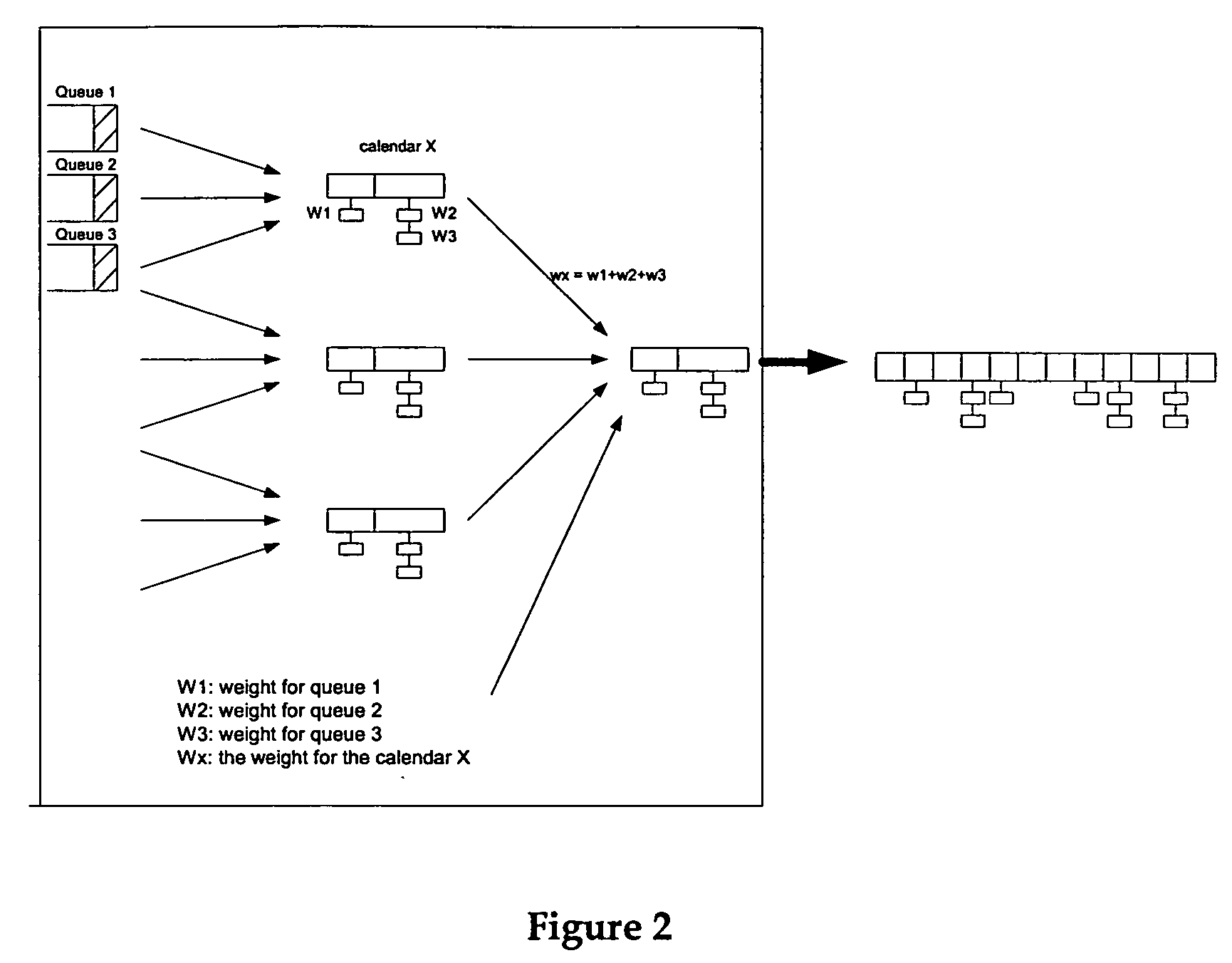

Two-slot dynamic length WFQ calendar

A system and method of scheduling and servicing events in a communications network are described. To provide improved efficiency while maintaining fairness to all traffic a two slot dynamic length Weighted Fair Queuing (WFQ) calendar is implemented. The two slot calendar can transformed to provide fine granularity utilizing a hierarchical WFQ scheme.

Owner:ALCATEL LUCENT SAS

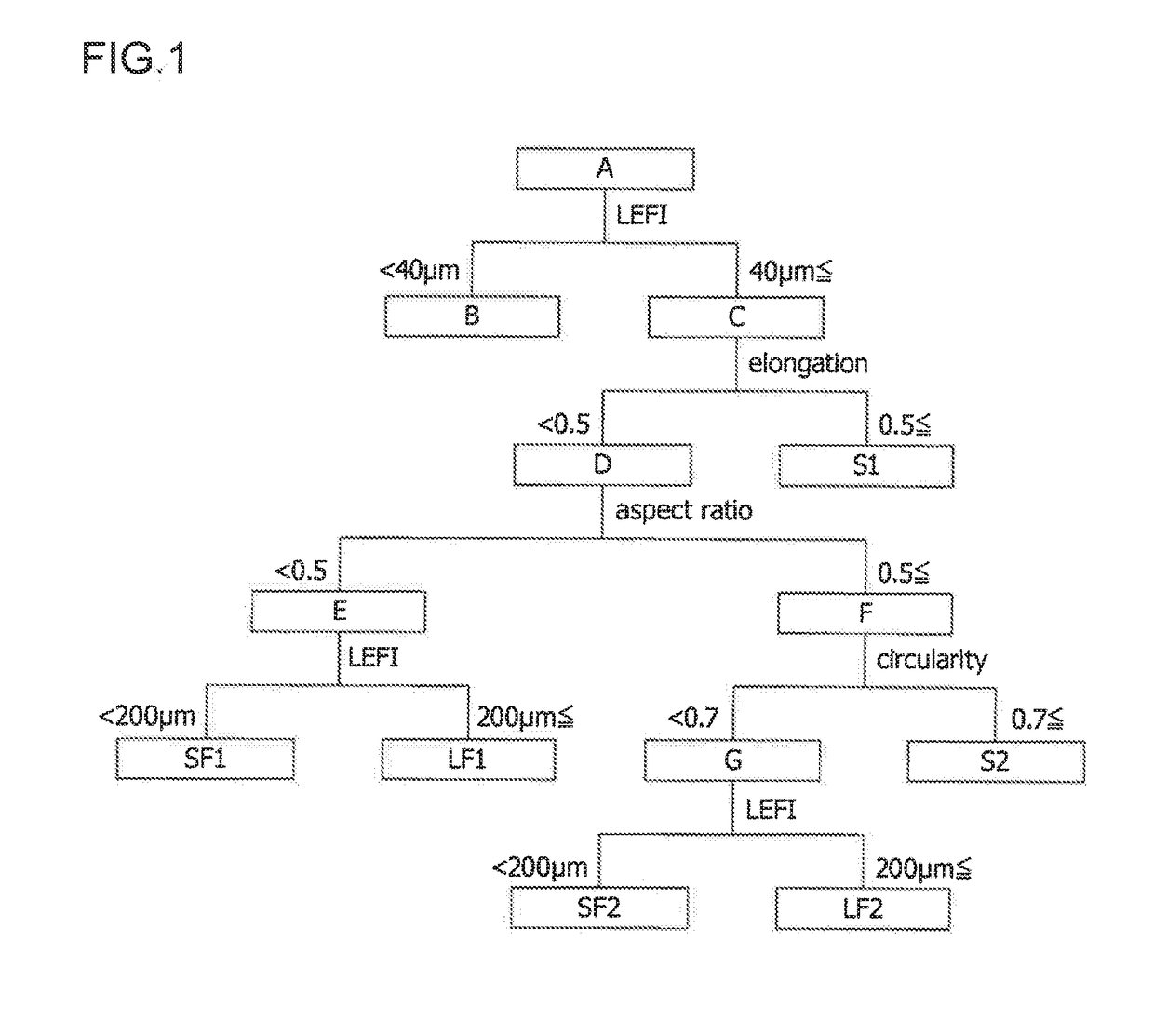

Low-substituted hydroxypropyl cellulose, production method thereof, and solid preparation

ActiveUS20180100029A1High-quality solid preparationLess cappingPowder deliveryOrganic active ingredientsFiberLow-substituted hydroxypropylcellulose

There are provided low-substituted hydroxypropyl cellulose (L-HPC) having good compressibility and capping-prevention performance, and others. Specifically, provided are L-HPC having a hydroxypropoxy content of 5 to 16% by weight, a volume fraction of long fibrous particles of 20 to 40% and a volume fraction of short fibrous particles of 26 to 60% with the proviso that the latter is greater than the former; and a solid preparation containing the L-HPC. Also provided is a method for producing the L-HPC including the steps of: bringing powdery pulp having a length-weighted mean width of 10 to 25 μm into contact with an alkali metal hydroxide solution, reacting the alkali cellulose with propylene oxide, and neutralizing the alkali metal hydroxide present in the reaction product with an acid to precipitate crude low-substituted hydroxypropyl cellulose in the absence of a step of dissolving a portion or all of the reaction product.

Owner:SHIN ETSU CHEM IND CO LTD

Fibers for spunlaced products

InactiveUS20050279473A1Efficient processingReduce the amount requiredNon-fibrous pulp additionNatural cellulose pulp/paperCellulose fiberLength weight

Fractionated cellulosic fibers having a length weighted average fiber length of at least 2.4 mm and less than 2% by weight of fines. In another embodiment the fractionated cellulosic fibers have a length weighted average fiber length of at least 3.5 mm. In another embodiment the fractionated cellulosic fibers have a length weighted average fiber length in the range of 2.4 mm to 3.8 mm. The fibers may be used in spunlacing or airlacing.

Owner:WESTLAND JOHN A +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com