Weighing method for determining liquid level in wellbore of gas well

A technology of liquid level position and determination method, which is applied to the determination of the liquid level depth of gas wells and the field of liquid-accumulating gas wells, can solve problems such as affecting the accuracy of calculation results, consuming manpower and material resources, and achieves simple testing, reliable principle, and accurate results. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

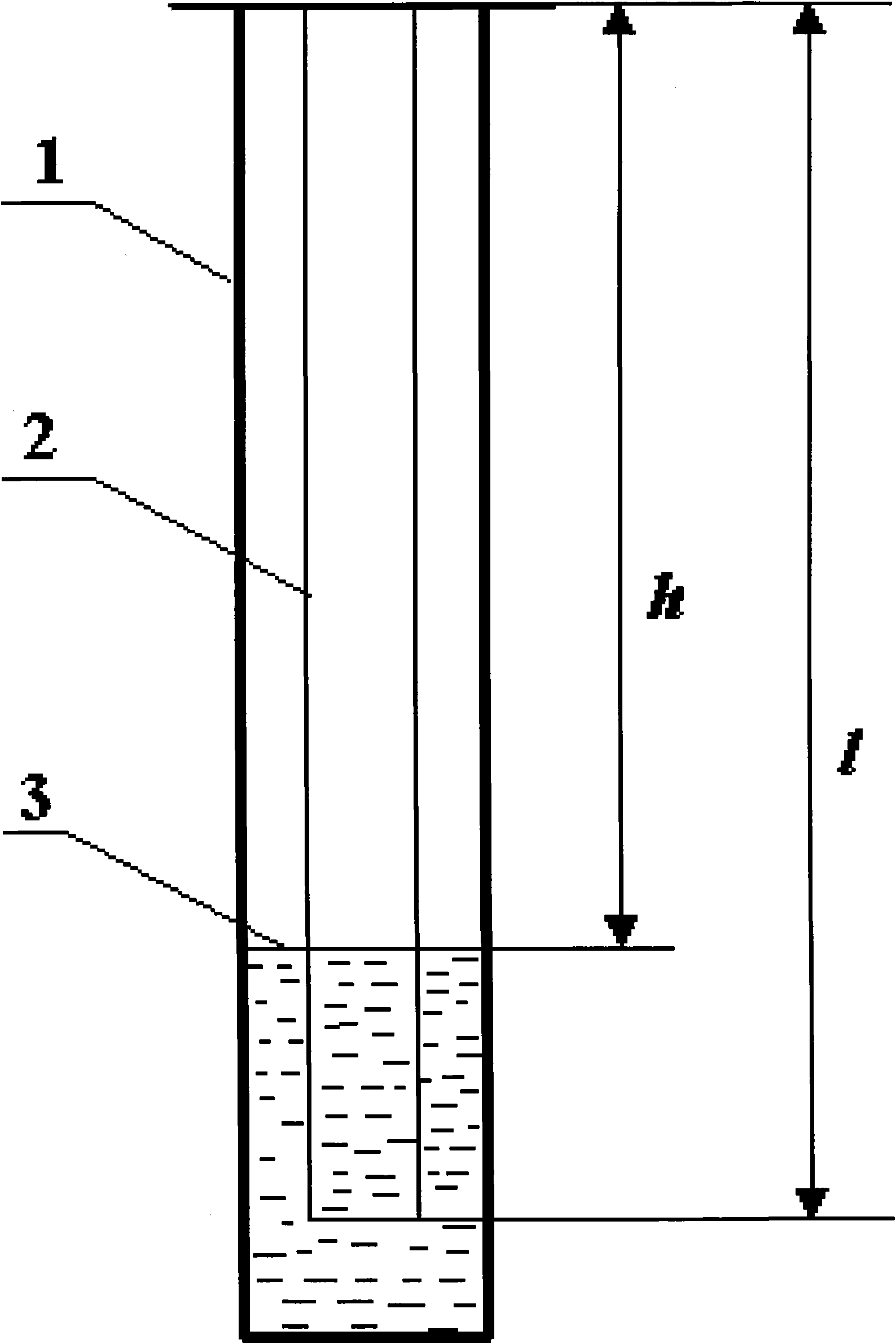

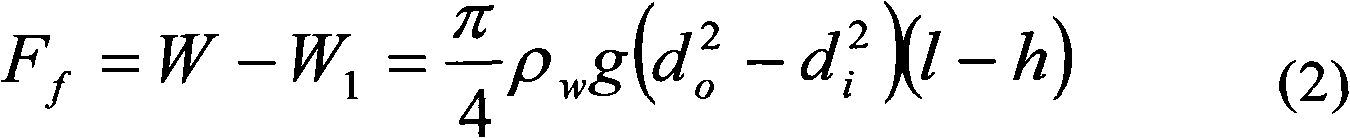

[0031] Embodiment 1: The present invention will be further described in detail by taking the method of determining the position of the wellbore liquid level of a weighing gas well once as an example.

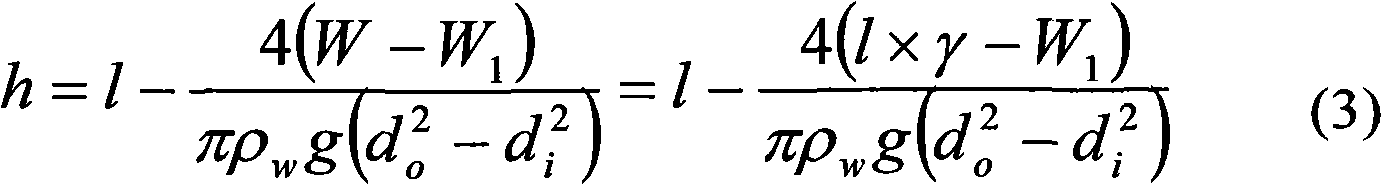

[0032] A certain gas well has a tubing string 2 in the casing 1. Tubing string 2 uses 2 7 / 8 "Thickened tubing is connected. The tubing string 2 has a length of 2200m, an outer diameter of 73mm, and an inner diameter of 62mm. The average weight of a unit tubing string 2 is 94.86N / m. The liquid density is 1010kg / m 3 , the weight of the tubing string 2 in the liquid measured at the wellhead after the gas well flooded is 204428N. Substitute the above information into the formula:

[0033] h = l - 4 ( l × γ - W 1 ) π ...

Embodiment 2

[0035] Embodiment 2: still carry out in the gas well of embodiment 1. A tubing string 2 is lowered in the casing 1 . Tubing string 2 uses 2 7 / 8 "Thickened oil pipes are connected. The length of the oil pipe string 2 is 2200m, the outer diameter is 73mm, and the inner diameter is 62mm. The average weight of the unit oil pipe string 2 is 94.86N / m. The liquid density is 1010kg / m 3 , the weight of the tubing string 2 in the liquid measured at the wellhead after the gas well is flooded is 202120N, and the above data are substituted into the formula:

[0036] h = l - 4 ( l × γ - W 1 ) π ρ w g ( d o ...

Embodiment 3

[0038] Embodiment 3: 14 times in 3 months are weighed and the distance h of the liquid level from the wellhead after the liquid accumulation in the gas well obtained by calculation is drawn into a curve corresponding to the time, and the distance h between the liquid surface and the wellhead after the liquid accumulation in the gas well is found out Elevation law. According to the liquid loading law of the gas well, it is predicted when the next liquid drainage measure of the gas well should be carried out. Those skilled in the art are familiar with gas well drainage measures and will not describe them in detail.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com