Anchor rod static pressure pile pre-stressed force sealing pile structure and construction method thereof

An anchor bolt static pressure pile, pre-stressing technology, applied in the direction of foundation structure engineering, sheet pile wall, construction, etc., can solve the problems of low utilization rate of pile pressing equipment, uneven settlement of foundation, shortening construction period, etc., to avoid The effect of uneven settlement, improving the turnover rate and ensuring the reinforcement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

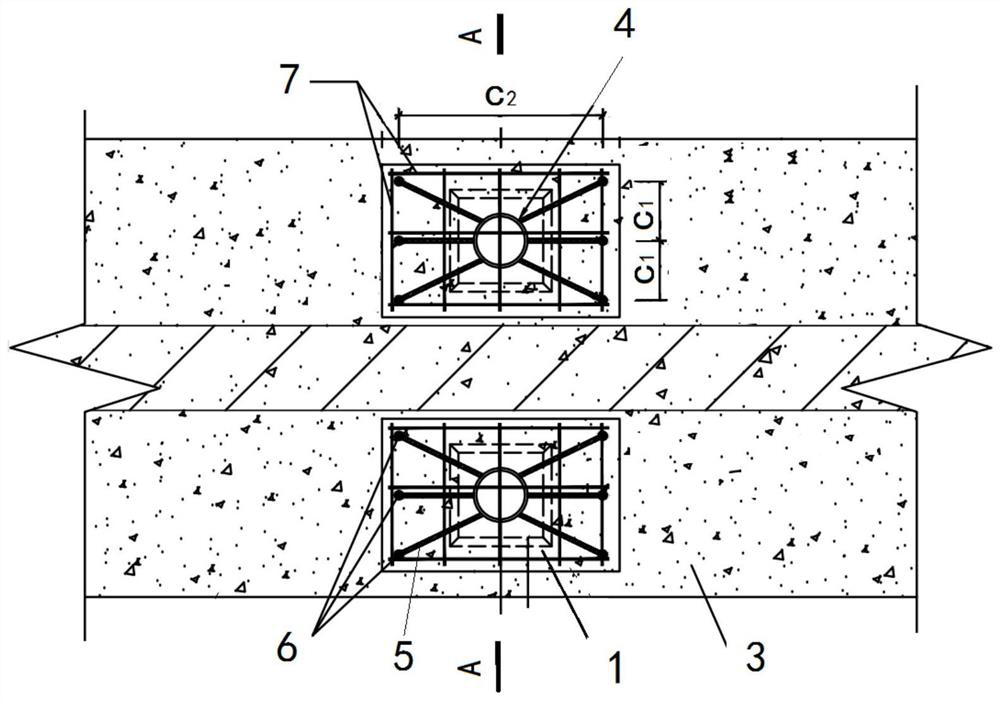

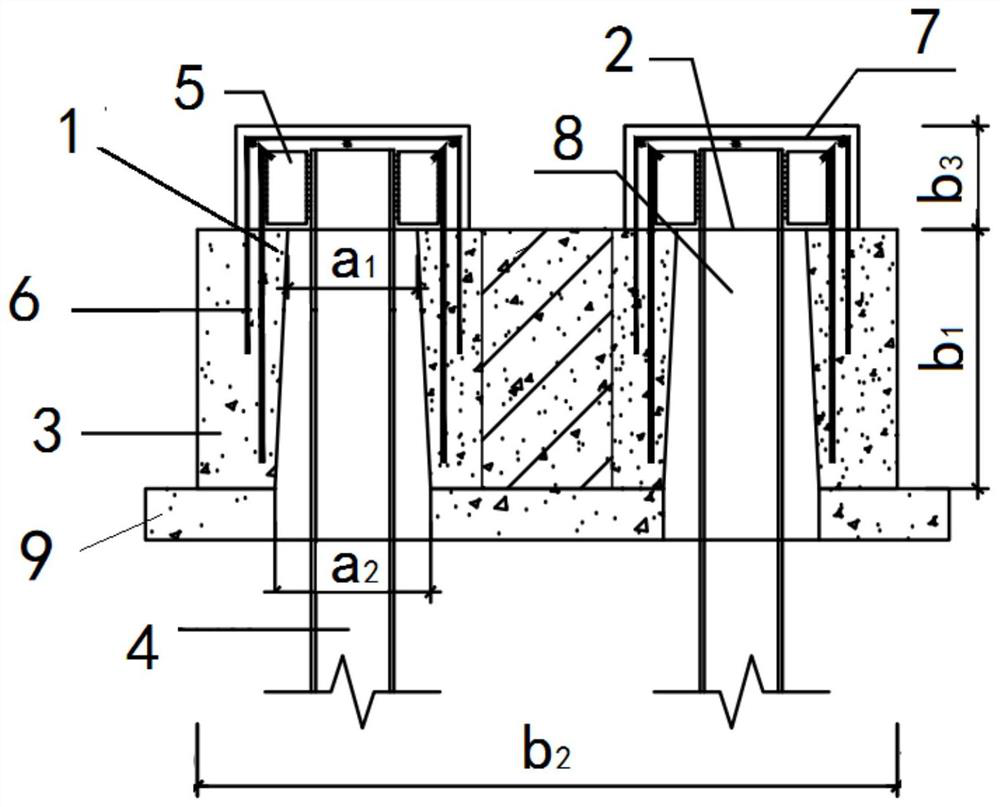

[0028] Embodiment 1: A kind of bolt static pressure pile prestressed pile sealing structure, such as figure 1 As shown, in the middle of the original foundation beam 1, there is preset a truss-shaped pressure pile hole 2 with the small end facing upwards, and the distance between the upper end of the pile hole 2 is a 1 is 250mm, the distance between the bottom edge of the pile hole a 2 is 300mm, and the two sides of the original foundation beam 1 are widened to form a new foundation beam 3, and the height of the pile hole 2 is the height b of the new foundation beam 3 1 is 500mm, add the total width b of foundation beam 3 2 The pile 4 made of steel pipe is pressed into the foundation through the pile hole 2. The diameter of the pile 4 is φ159mm. A small section of the top of the pile 4 is exposed above the newly added foundation beam 3. The exposed part of the pile 4 has a length of b 3 200mm, on the outer side of this small section of pile, there are several reinforced stee...

Embodiment 2

[0033] Embodiment 2: according to the construction method of a kind of bolt static pressure pile pre-stressed pile sealing structure described in the above claims, the steps are:

[0034] 1) A newly added foundation beam 3 is formed by widening both sides of the original foundation beam 1, and anchor rods 6 are embedded symmetrically in the newly added foundation beam 3, and the newly added foundation beam 3 is superimposed and connected to the original foundation cushion 9 above;

[0035] 2), using the pile-pressing mechanical equipment to press the pile 4 through the prism-shaped pile-pressing hole 2 of the original foundation beam 1;

[0036] 3), the pressure pile 4 reaches the preset depth and continues to apply the holding pressure;

[0037] 4), remove the soil in the pile pressure hole 2 and the surrounding pile cap beam area, and clean the muddy water in the pressure pile hole wall and the pile pressure hole;

[0038] 5), one end of the prefabricated reinforced steel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com