Tool for pocket hole of short cylindrical roller bearing retainer and pocket hole method thereof

A bearing cage and short cylindrical roller technology, which is applied in broaching equipment, manufacturing tools, metal processing equipment, etc., can solve the inconsistency of the pocket axial position and the accuracy of the pocket circumferential position and affect the machining of the cage. quality and other issues, to achieve the effect of improving bearing performance and reliability, solving accuracy stability and consistency problems, and facilitating positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

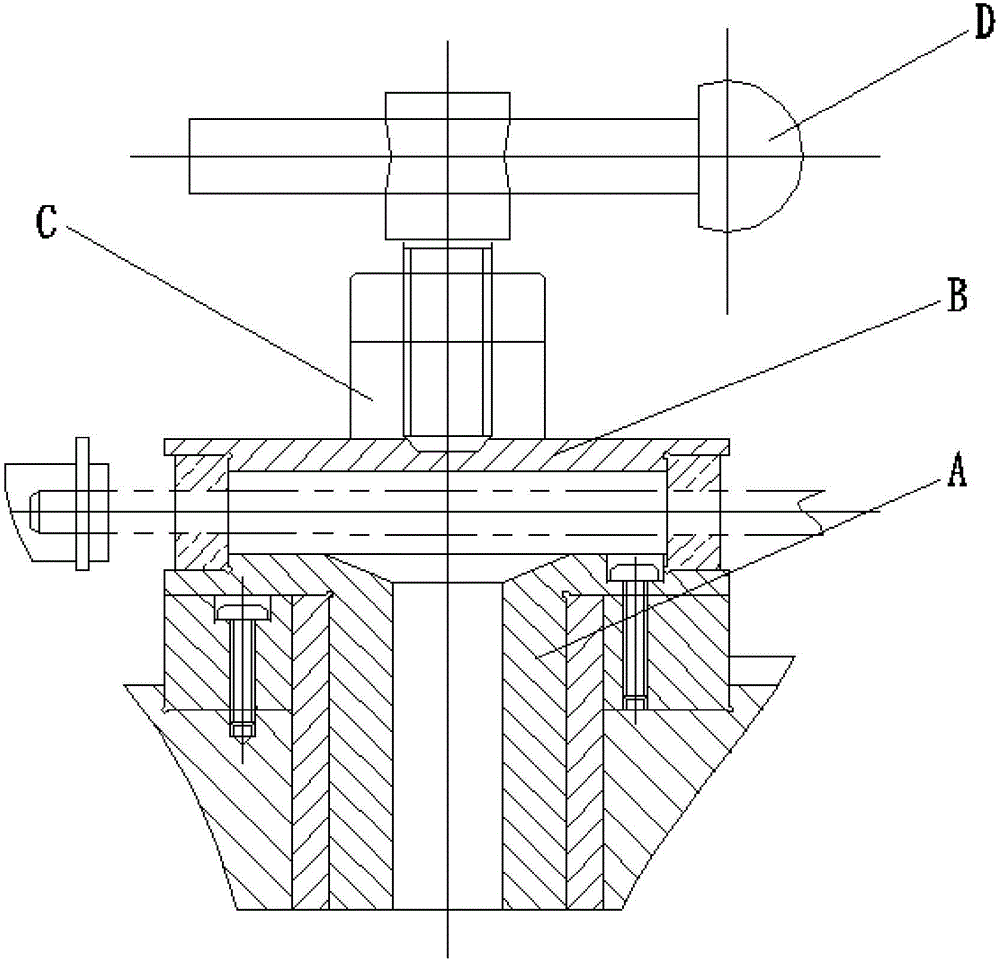

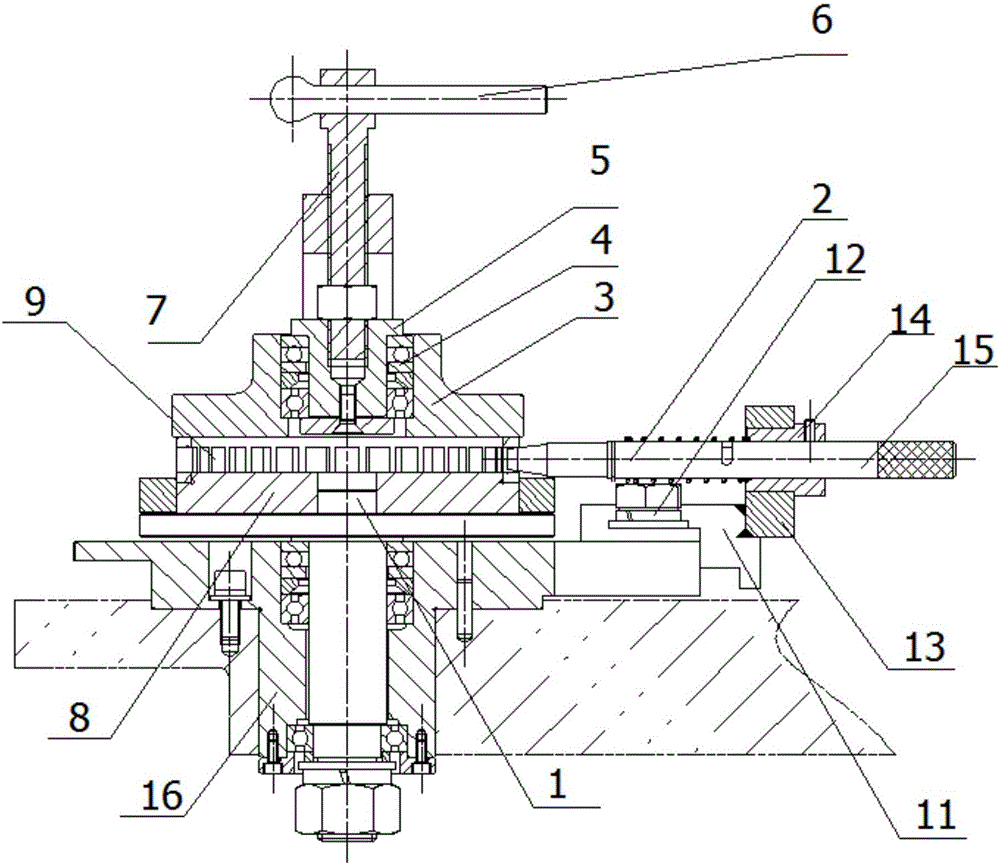

[0036] Specific implementation mode one: combine figure 2 Describe this embodiment, a short cylindrical roller bearing cage pocket tooling of this embodiment, which includes a positioning rotating shaft 1, a positioning pin 2, a cover plate 3, a pressing block 5, a tightening rod 6, and a pressing rod 7 And the positioning shaft 8, the positioning shaft 8 can be rotatably installed on the workbench, the positioning rotating shaft 1 is set in the center hole on the positioning shaft 8, the cage 9 is installed on the positioning shaft 8, and the cover plate 3 is press-fitted on the cage 9 Above, there is a stepped hole in the middle of the cover plate 3, the pressure block 5 is rotatably installed in the stepped hole of the cover plate 3, the pressure rod 7 is screwed vertically in the pressure block 5, and the tightening rod 6 is horizontally installed on the pressure rod 7, the positioning pin 2 is detachably inserted in any pocket of the cage 9.

specific Embodiment approach 2

[0037] Specific implementation mode two: combination figure 2 This embodiment is described. This embodiment also includes a plurality of bearings 4 , and the pressure block 5 is connected to the cover plate 3 through the plurality of bearings 4 installed in the stepped holes. Such arrangement facilitates the smooth press-fitting and fixing of the pressing block 5 to the cage through the cover plate, saves labor intensity for the operator, and improves the press-fitting efficiency at the same time. Other compositions and connections are the same as in the first embodiment.

specific Embodiment approach 3

[0038] Specific implementation mode three: combination figure 2 Describe this embodiment, this embodiment also includes a positioning pin transmission assembly, the positioning pin transmission assembly includes a fixed base 11, a support frame 12, a feed seat 13, a feed sleeve 14 and a transmission rod 15, and the support frame 12 and the fixed base 11 are in turn Installed on the workbench, and the support frame 12 is installed close to the side of the positioning shaft 8, a working hole is opened horizontally on the feed seat 13, the feed seat 13 is installed on the fixed base 11, and the feed sleeve 14 is inserted into the feed seat 13 In the working hole, the transmission rod 15 is set on the support frame 12 after passing through the feed sleeve 14, and the end of the transmission rod 15 near the support frame 12 side is connected with the non-insert end of the positioning pin 2. Such setting not only facilitates the positioning and installation of the positioning pin, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com