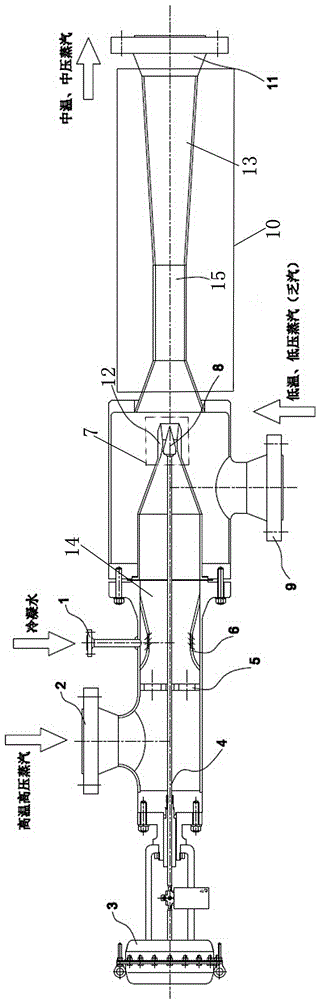

Integrated steam exhaust temperature reduction pressurizer

A technology of steam desuperheating and supercharger, which is applied in the direction of direct contact heat exchanger, fluid mixer, heat exchanger type, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

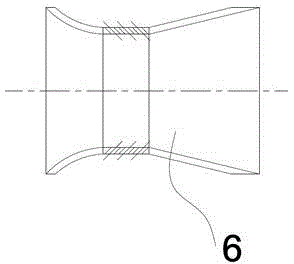

[0024] When the integrated exhaust steam desuperheating supercharger is working, high-pressure and high-temperature superheated steam enters the body 14 through the steam inlet flange 2, and condensed water enters the desuperheating flow control ring 6 through the condensed water inlet flange 1, and the desuperheating flow control ring 6 The outer contour is similar to the Venturi structure, the main purpose is to increase the flow rate of the high temperature and high pressure steam passing through here, which is beneficial to the mixing of steam and condensed water.

[0025] The desuperheating flow control ring 6 is evenly covered with tangential flow holes in the radial direction of 360°. It has three functions. First, the flow of condensed water can be preliminarily controlled through the number of flow holes; second, the tangential arrangement can make the condensed water rotate and further improve Mixing with steam; the third is that the flow holes are evenly arranged in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com