Loader static pressure transmission control system

A technology of transmission control and loader, which is applied in the direction of transmission control, mechanical equipment, components with teeth, etc., can solve the problems of low production efficiency, high labor intensity, easy flameout, etc., and achieve improved control safety and maintenance Convenient and convenient stepless speed regulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

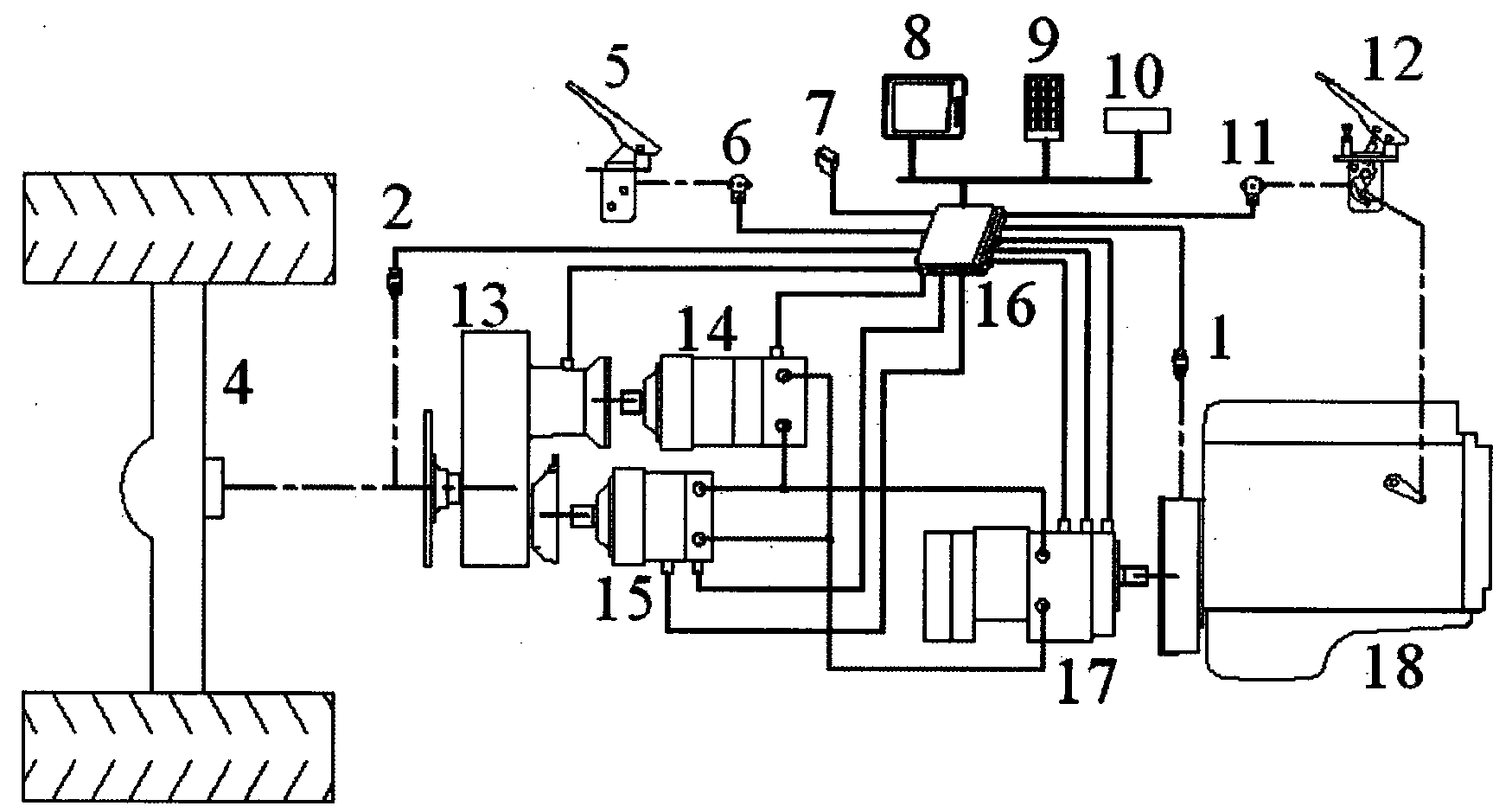

[0026] In order to make the present invention more comprehensible, preferred embodiments are described in detail below with accompanying drawings.

[0027] The present invention is a loader hydrostatic transmission control system, such as image 3 As shown, it includes a controller 16, the controller 16 is respectively connected with the transmission shaft speed sensor 2, the brake pedal displacement sensor 6, the direction switch 7, the display 8, the operation panel 9, the diagnosis port 10, the accelerator pedal displacement sensor 11, the engine speed Sensor 1, travel pump 17, first motor 14, second motor 15, gearbox 13 are connected, travel pump 17 is connected with engine 18, one end of gearbox 13 is connected with bridge 4, and the other end of gearbox 13 is connected with first motor 14. The second motor 15 is connected. The transmission shaft speed sensor 2 is connected with the output shaft of the gearbox 13, the brake pedal displacement sensor 6 is connected with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com