Superheat water vapor in-situ pyrolysis oil-rich coal efficient oil extraction method

A technology of superheated steam and in-situ pyrolysis, which is applied in earth-moving drilling, fluid production, wellbore/well components, etc. effect of time, diffusion reduction, and pyrolysis temperature increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

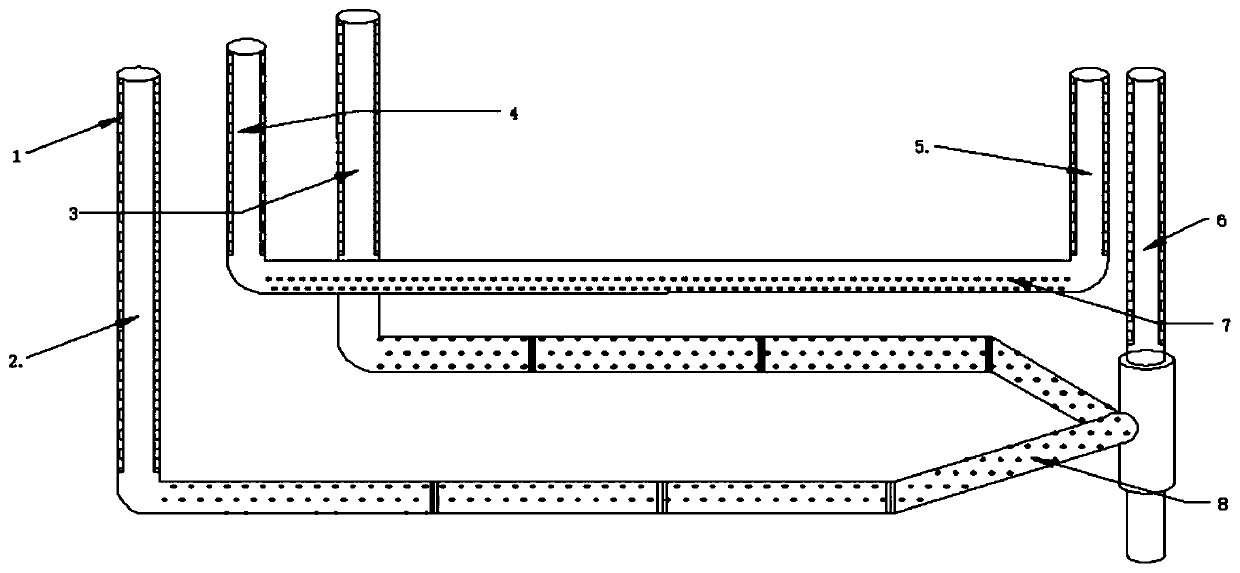

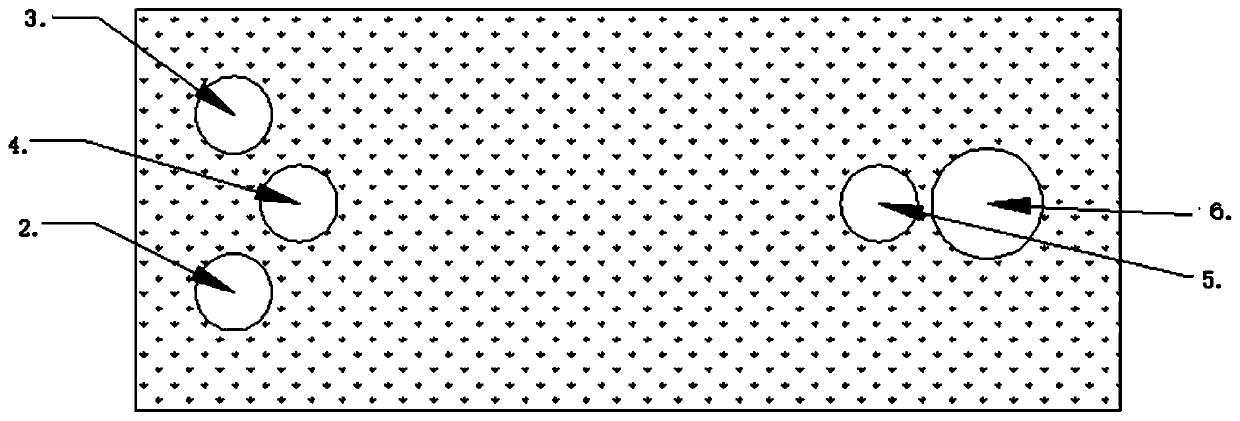

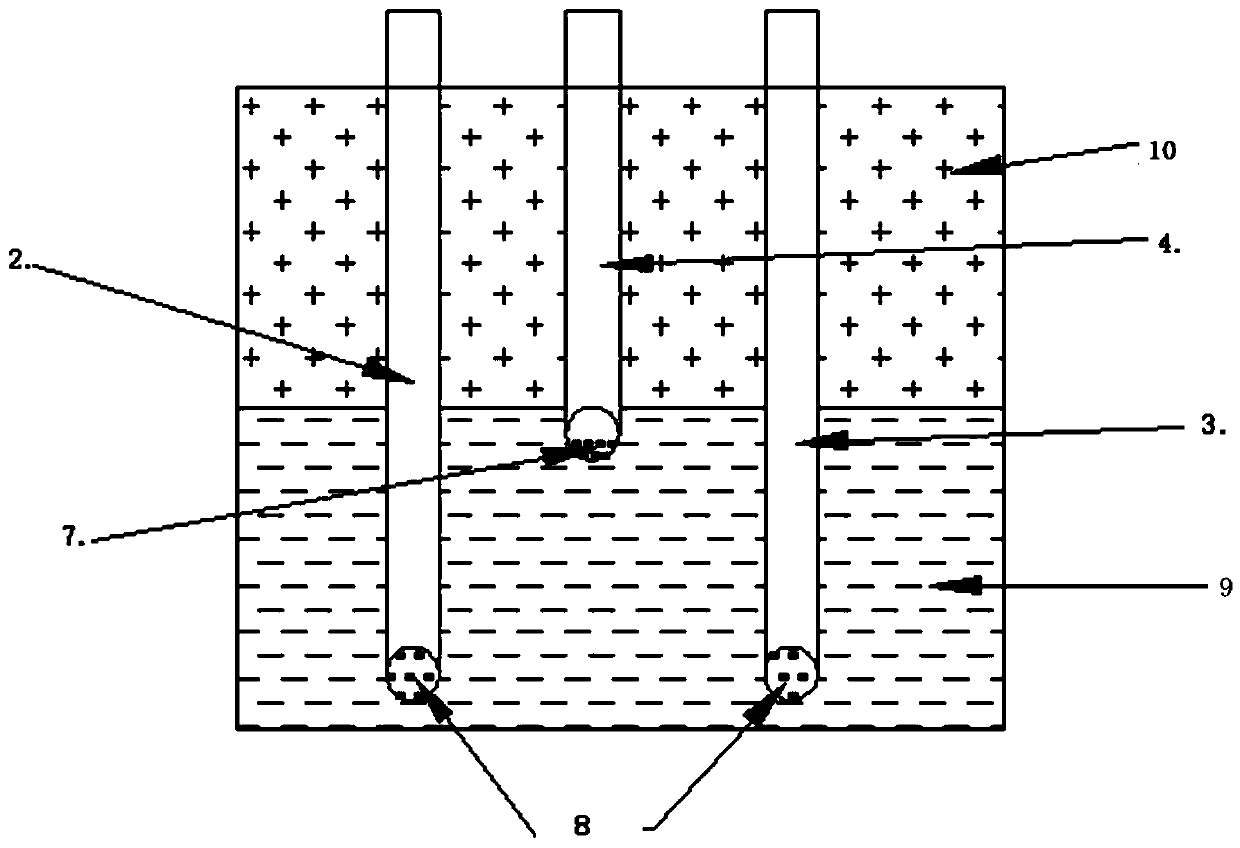

[0033] like Figure 1-4 As shown, in the method of this embodiment, the vertical well 6 is first drilled, and two horizontal wells are drilled as heat injection wells A and B again. , B is connected with vertical shaft 6, the elevation of the coal-seeing section of the heat injection horizontal well is greater than that of the vertical well. Channel, production well A is drilled above heat injection wells A and B, and the horizontal well distance of production well A is greater than 500m, of which 500m refers to the horizontal distance of the production well in the coal seam, production well A and production well B are connected, and the production well A uses a screen tube, and water or supercritical carbon dioxide is introduced through the heat injection wells A and B, and the coal seam is fractured by the process of staged perforation and staged fracturing respectively, and the mixed slurry of iron ore and lime is injected in stages. After the completion of the perforation...

Embodiment 2

[0035] Compared with Embodiment 1, the fracturing method of this embodiment is different from that of Embodiment 1. Embodiment 1 adopts hydraulic fracturing, while this embodiment adopts controllable shock wave fracturing. Different, it will affect the subsequent injection of steam and limestone slurry, which will affect the pyrolysis efficiency and oil production rate of oil-rich coal. Embodiment 2 will be specifically described below.

[0036] like Figure 1-4As shown in the figure, the vertical well 6 is drilled, and two horizontal wells are drilled as heat injection wells A and B again. The heat injection wells are run with casing. The distance between the horizontal wells of the heat injection wells A and B is greater than 500m, and the heat injection wells A and B are communicated with the vertical well 6. , the elevation of the coal-seeing section of the heat-injection horizontal well is greater than that of the vertical shaft. The vertical well can effectively dischar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com