Delayed coking method for processing high-acid crude oil

A high-acid crude oil, delayed coking technology, applied in the field of thermal cracking deacidification process, to reduce corrosion, avoid severe corrosion, and reduce temperature

Active Publication Date: 2012-11-21

CHINA PETROLEUM & CHEM CORP +1

View PDF9 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Both of the above two methods need to heat the high-acid crude oil in a heating furnace and go through a stage of strong corrosion. Therefore, these two methods cannot avoid the severe corrosion of the heating equipment by the naphthenic acid in the high-acid crude oil

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1-5

[0039] The calculation method of deacidification rate is as follows: deacidification rate=(total acid value of high-acid crude raw material-total acid value of obtained liquid phase product) / total acid value of high-acid crude raw material×100%.

[0040] All experiments in the examples use the same raw material oil, aiming to compare the deacidification effects under different operating conditions.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

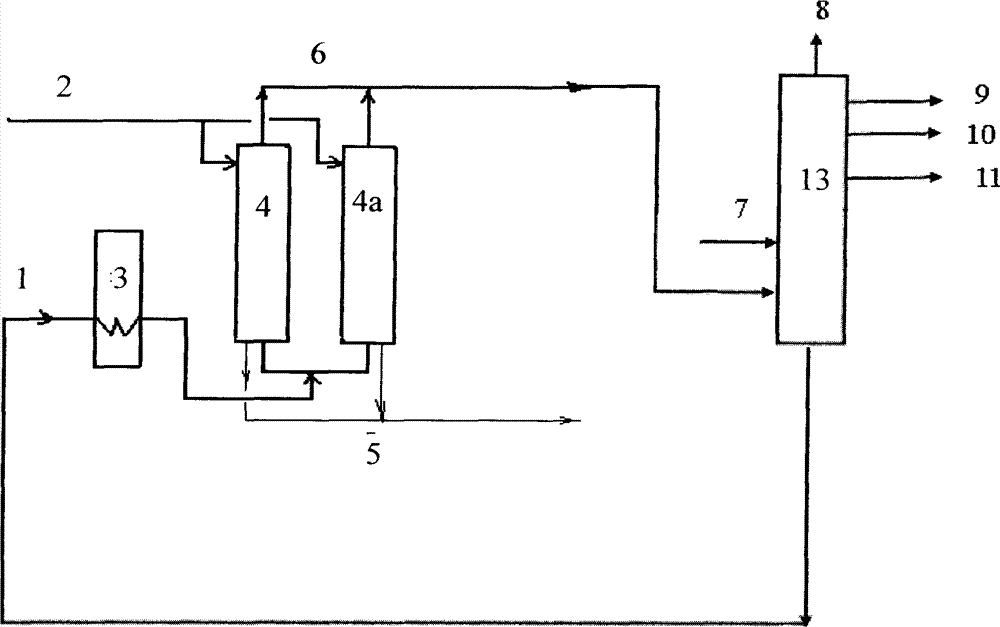

The invention discloses a method for processing high-acid crude oil by a delayed crude oil process. In the method, low-temperature high-acid crude oil enters the upper part of a reactor; high-temperature low-acid coking raw material enters the bottom of the reactor; a high-temperature oil gas generated from the low-acid coking raw material through pyrolysis is mixed with the low-temperature high-acid crude oil on the upper part of the reactor; therefore, the high-acid crude oil is pyrolyzed and deacidified at an appropriate high temperature so as to fulfill the aim of deacidification; and simultaneously, the injection of the low-temperature high-acid crude oil reduces the cracking temperature of the low-acid coking raw material, shortens the pyrolysis time of a low-acid raw material, and reduces secondary reactions, thereby reducing the coke formation rate and prolonging the stable operating period of a single tower. The delayed coking method for processing the high-acid crude oil hasthe characteristics that the preheating temperature of the high-acid crude oil can avoid a strong corrosion phase of an acid, and can reduce or even avoid the corrosion of the acid on heating equipment even below a corrosion temperature.

Description

technical field [0001] The invention belongs to a thermal cracking deacidification process, in particular to a method for removing acidic compounds in high-acid crude oil during delayed coking operation. Background technique [0002] In recent years, the exploitation of high-acid crude oil in the world has increased year by year, and the higher the acid value of crude oil, the lower the price. Therefore, it will have better economic benefits for refineries to process high-acid crude oil. However, since the acid compounds contained in high-acid crude oil mainly exist in the form of naphthenic acid, naphthenic acid is easy to react with iron or iron sulfide, causing serious corrosion to refinery equipment. The biggest problem is how deacidification can reduce equipment corrosion. [0003] The corrosion effect of naphthenic acid in high-acid crude oil on equipment is greatly affected by temperature, and there is almost no corrosion effect below 220°C. As the temperature incre...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C10G9/14

Inventor 蒋立敬张学萍勾连忠

Owner CHINA PETROLEUM & CHEM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com