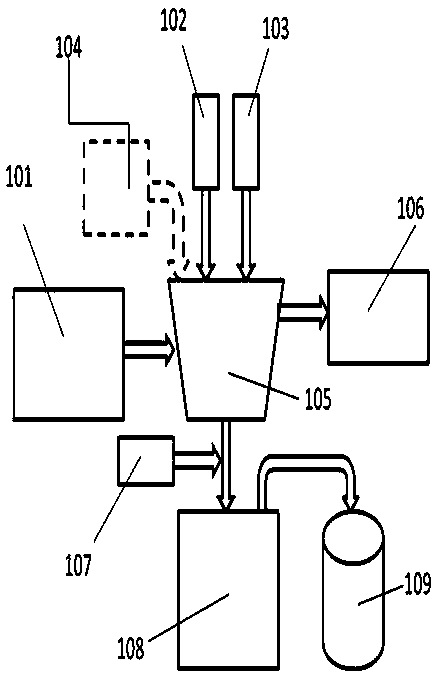

Circular treatment method and process system for fluorine-containing high-ammonia-nitrogen industrial wastewater

A technology for industrial wastewater and recycling treatment, applied in multi-stage water treatment, water/sewage treatment, neutralized water/sewage treatment, etc., can solve the problems of poor continuity, lack, high cost of chemical dosing, etc., to achieve uniform heating and low investment And the effect of low operating cost and shortened pyrolysis time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] First place the 1 m 3 The concentration of ammonia nitrogen is 500 mg / L, F - Wastewater with a concentration of 250 mg / L is added to the raw water adjustment tank, and then the pH is adjusted to 8, and then the wastewater in the adjustment tank is introduced into the mechanical acceleration clarifier tank, according to Ca 2+ :F - :Mg 2+ :NH 4 + =5:1:2.5:2 Add medicament and mechanically stir for 90 minutes, the separated clear water rises upwards and flows out through the sump, and the sinking solid-liquid mixture is transferred to the box-type microwave reactor through the pump. After the pumped solid-liquid mixture is placed in the fluidized microwave reactor, the molar ratio of NH 4 + :OH - =1:1 After adding soda ash and stirring and mixing, turn on the microwave reactor, set the power to 0.4 KW, microwave radiation for 10 min, and the ammonia gas generated by the drying and decomposition of the mixture is passed into the acid solution through the air duct at ...

Embodiment 2

[0021] First place the 1 m 3 The concentration of ammonia nitrogen is 500 mg / L, F - Wastewater with a concentration of 250 mg / L is added to the raw water adjustment tank, and then the pH is adjusted to 10, and then the wastewater in the adjustment tank is introduced into the mechanical acceleration clarifier tank, according to Ca 2+ :F - :Mg 2+ :NH 4 + =5.5:1:2.5:2 Add medicament and mechanically stir for 90 minutes to react. The separated clear water rises upwards and flows out through the sump. The sinking solid-liquid mixture is transferred to the box-type microwave reactor through the pump. After the pumped solid-liquid mixture is placed in the fluidized microwave reactor, the molar ratio of NH 4 + :OH - =1:1 Add soda ash and stir to mix, then turn on the microwave reactor, set the power to 0.4 KW, irradiate with microwave for 10 minutes, and the ammonia gas produced by the drying and decomposition of the mixture is passed into the acid solution through the air duct...

Embodiment 3

[0023] First place the 1 m 3 The concentration of ammonia nitrogen is 500 mg / L, F - Wastewater with a concentration of 250 mg / L is added to the raw water adjustment tank, and then the pH is adjusted to 8, and then the wastewater in the adjustment tank is introduced into the mechanical acceleration clarifier tank, according to Ca 2+ :F - :NH 4 + =5.5:1: 2 Add chemicals and stir, and at the same time introduce wet flue gas magnesium desulfurization wastewater from thermal power plants (Mg 2+ The concentration is 6532 mg / L) about 100 L, mechanically stirred for 90 minutes, the separated clear water rises upwards, flows out through the sump, and the sinking solid-liquid mixture is transferred to the box-type microwave reactor through the pump. After the pumped solid-liquid mixture is placed in the fluidized microwave reactor, the molar ratio of NH 4 + :OH - =1:1 Add soda ash and stir to mix, then turn on the microwave reactor, set the power to 0.4 KW, microwave radiation fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com