Integrated device and method for preparing oil product and synthetic gas from fine coal

An integrated device and synthesis gas technology, which is applied in the petroleum industry, the combination of fuel pre-dry distillation, the preparation of liquid hydrocarbon mixtures, etc., can solve the problems of large environmental pollution, high dust content of tar and gas, and low tar yield, etc. To achieve the effect of shortening the contact time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0071] The present invention will be described in further detail below in conjunction with the accompanying drawings. .

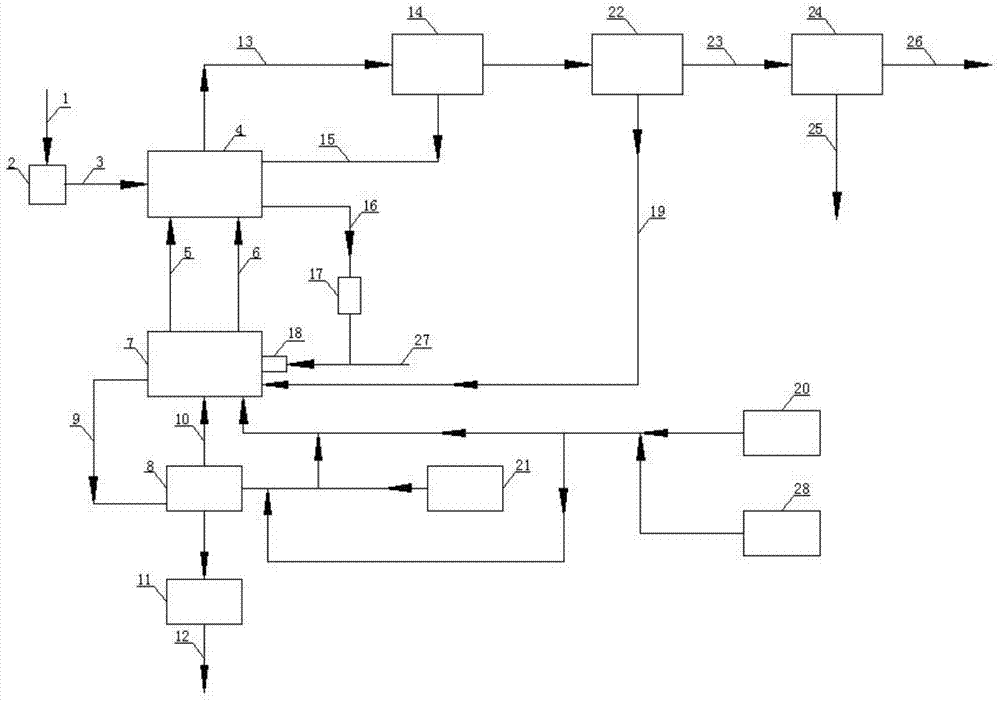

[0072] see figure 1 , including an integrated reaction system, a recycling system and a deep separation and purification system24;

[0073] The integrated reaction system includes a gasification section 7 and a fast pyrolysis section 4, wherein the gasification section 7 communicates with the fast pyrolysis section 4 through a high-temperature gas pipeline 5 and an entrained particle pipeline 6, and the raw material inlet of the fast pyrolysis section 4 The coal feed pipeline 3 is connected with the feed system 2, and a solid circulation channel 18 is opened on the gasification section 7, and an outlet of the fast pyrolysis section 4 is connected with the solid circulation channel 18 through the circulation particle pipeline 16, and the gasification section 7. The lower end is also communicated with the mixed gas of oxygen 20, air 28 and steam 21 through ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com