Method for comprehensively recovering all components of waste crystalline silicon photovoltaic module

A photovoltaic module, full-component technology, applied in the direction of electronic waste recycling, photovoltaic power generation, recycling technology, etc. Sheets and glass plates, etc., to shorten the pyrolysis time, speed up the pyrolysis speed, calorific value utilization rate without smoke pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

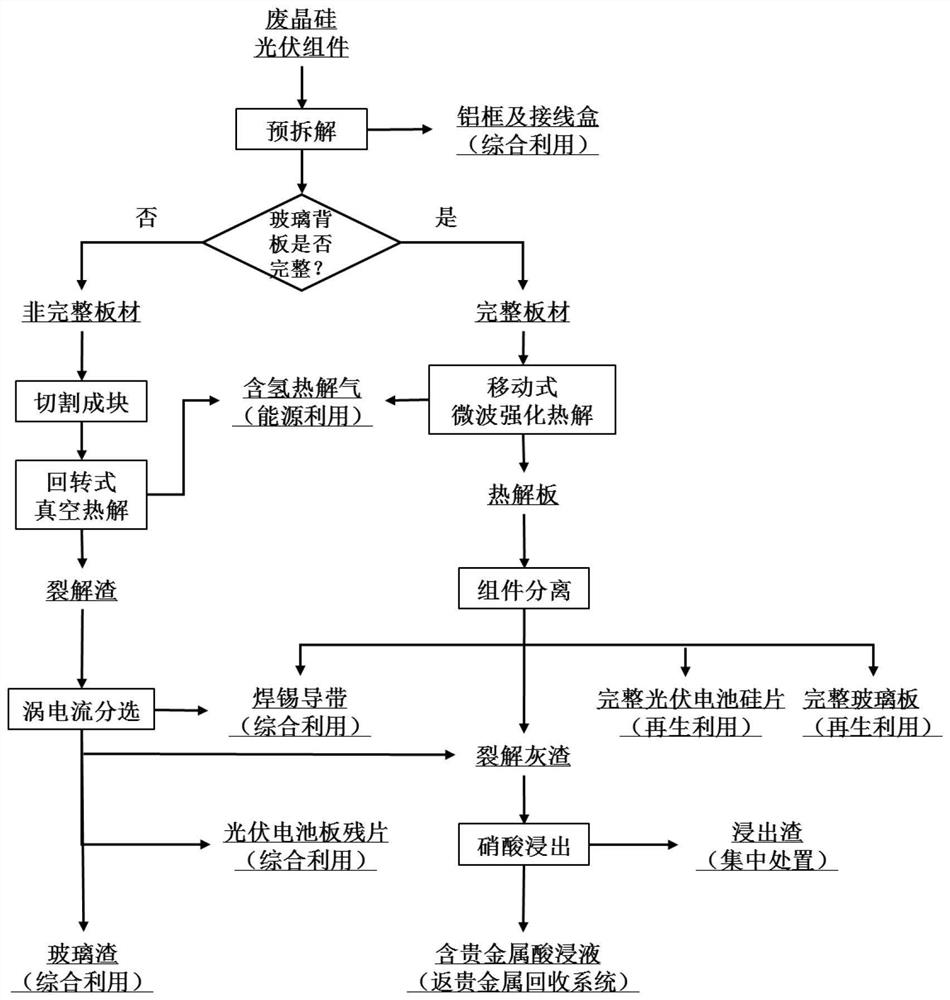

[0025] A method for comprehensive recovery of all components of a waste crystalline silicon photovoltaic module, comprising the following steps:

[0026] (1) Pre-sorting: including pre-disassembly and judging steps of whether the glass backplane is broken; the collected waste crystalline silicon photovoltaic panels are firstly pre-disassembled, and the aluminum frame and junction box are disassembled to obtain the aluminum frame and junction box. After pre-disassembly, according to whether the glass back plate is broken, incomplete and complete plates are obtained. The incomplete plates enter the rotary low-temperature vacuum pyrolysis recovery system for recycling, and the complete plates enter the mobile microwave-enhanced pyrolysis recovery system for recycling;

[0027] (2) Recycling of incomplete plates: the rotary low-temperature vacuum pyrolysis recovery system for incomplete plates includes cutting into blocks, rotary low-temperature vacuum pyrolysis and eddy current so...

Embodiment 2

[0031] Same as Example 1, the difference is:

[0032] In the rotary low temperature vacuum pyrolysis condition in step (2), the diameter of the furnace body is 1.2m, the effective heating length of the furnace body is 3.5m, the furnace body rotation speed is 5rpm, the pyrolysis temperature is 450°C, and the pyrolysis time is 20min.

[0033] The conditions of the mobile microwave-enhanced pyrolysis in step (3) are: microwave power 1200W, pyrolysis temperature 950°C, microwave pyrolysis time 5min, nitric acid leaching conditions are: the mass percentage of nitric acid is 70%, the leaching reaction temperature is 85°C, The leaching reaction time is 0.5h.

[0034] In the whole comprehensive recovery system of waste crystalline silicon photovoltaic modules, the comprehensive decomposition rate of EVA is 100%, and the comprehensive decomposition rate of TPT is 100%. The generated first hydrogen-containing pyrolysis gas and second hydrogen-containing pyrolysis gas can be used as Hea...

Embodiment 3

[0036] Same as Example 1, the difference is:

[0037] In the rotary low temperature vacuum pyrolysis condition in step (2), the diameter of the furnace body is 0.6m, the effective heating length of the furnace body is 1.8m, the furnace body rotation speed is 2rpm, the pyrolysis temperature is 350°C, and the pyrolysis time is 25min.

[0038] The conditions of microwave pyrolysis in step (3) are: microwave power 900W, pyrolysis temperature 750°C, microwave pyrolysis time 25min, nitric acid leaching conditions are: the mass percentage of nitric acid is 30%, the leaching reaction temperature is 45°C, and the leaching reaction Time 2.0h.

[0039] In the whole comprehensive recovery system of waste crystalline silicon photovoltaic modules, the comprehensive decomposition rate of EVA is 99.6%, and the comprehensive decomposition rate of TPT is 99.7%. The generated first hydrogen-containing pyrolysis gas and second hydrogen-containing pyrolysis gas can be used as Heat source for pyro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com