Grinding-disc pyrolysis reactor

A technology of pyrolysis reactor and furnace plate, which is applied in the chemical industry, can solve the problems of many useless components in gas, poor flue gas circulation, and low calorific value, and achieve small upper space of the furnace, fast heating rate, and large heat transfer area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] A kind of disc type pyrolysis reactor of the present invention, its preferred embodiment is:

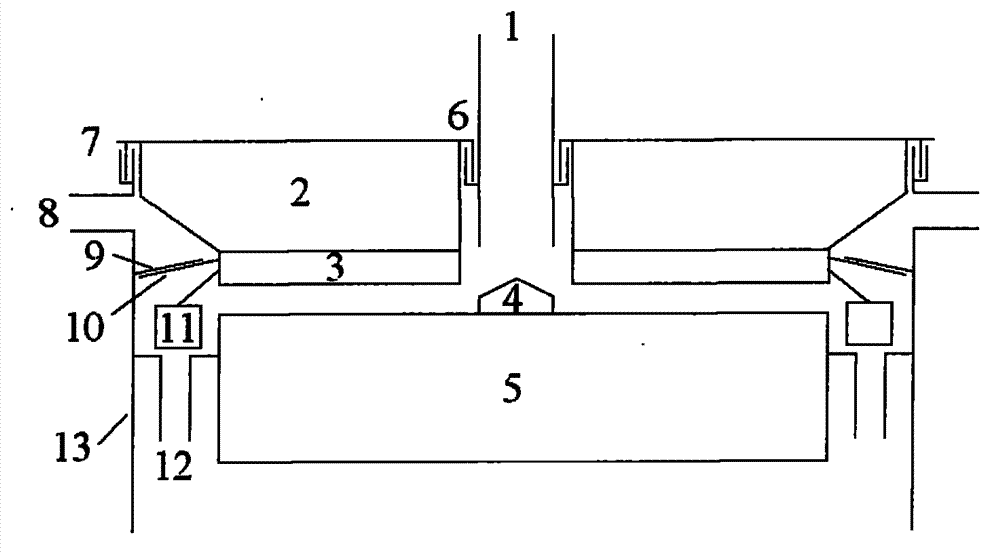

[0017] As shown in the figure, a disc type pyrolysis reactor of the present invention has a main body comprising: an upper furnace plate 2 , a distribution plate 3 , a lower furnace plate 5 and a furnace wall 13 .

[0018] The structural feature of the upper furnace plate 2 is that there is a feed pipe 1 in the center and a distribution plate 3 at the bottom, and the upper furnace plate 2 can rotate around the feed pipe 1 together with the distribution plate 3 . In order to form a closed space, a water seal 6 is provided between the upper furnace pan 2 and the feed pipe 1, and a water seal 7 is provided between the upper furnace pan 2 and the furnace wall 13. The water seals 6 and 7 can also be Use sand seal.

[0019] The feed pipe 1 is in the shape of an upright cylinder. In order to lay the material evenly and smoothly on the lower furnace tray 5, a cone 4 is provided to fa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com