Closed charcoal preparation apparatus

A preparation device and biochar technology, applied in the fields of biofuels, carbonization furnaces, special forms of dry distillation, etc., can solve the problems of increased scientific research cost, low preparation efficiency, damage, etc., to shorten the pyrolysis time, improve the preparation efficiency, and ensure the exhaustion The effect of oxygen environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The invention will be further described below in conjunction with specific embodiments, but the invention is not therefore limited to the following specific modes.

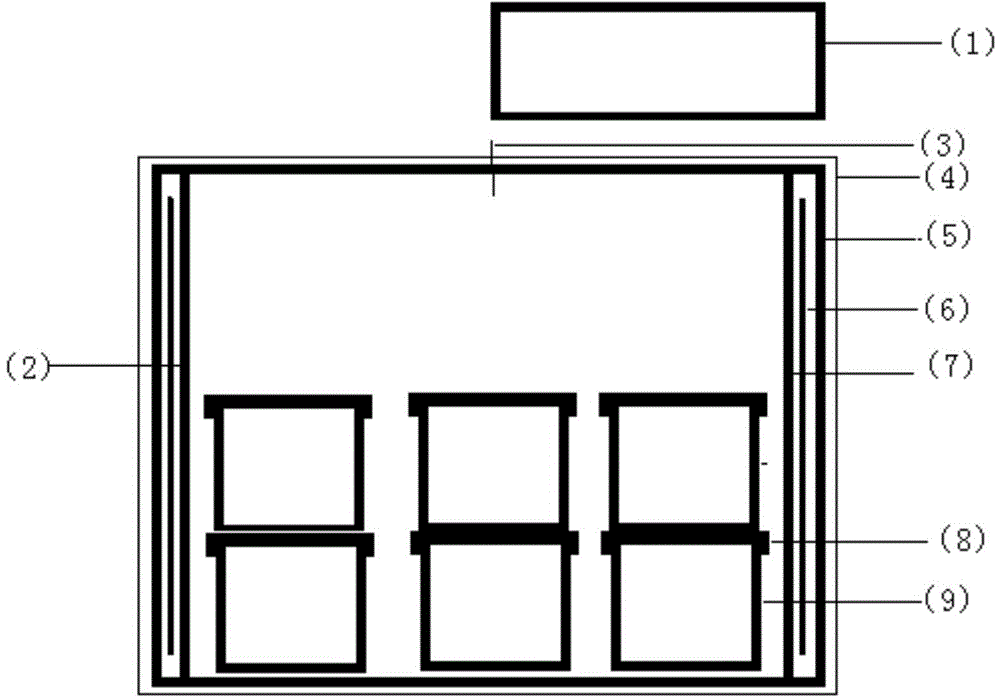

[0014] The biochar preparation process of the closed biochar preparation device in this embodiment is as follows: crushed organic matter enters the pyrolysis tank (9), tightens the lid (8) on the upper part of the pyrolysis tank (9), and then puts the pyrolysis tank (9) Put it into the heating box (2), close the heating box, turn on the power, adjust the temperature controller (1), set the pyrolysis temperature of the organic matter, and the organic matter is sealed and pyrolyzed in the pyrolysis tank (9). After the pyrolysis reaction is finished, open the heating box, and after the pyrolysis tank (9) cools down to room temperature, open the pyrolysis tank (9) and pour out the prepared biochar.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com