Mineral processing technology for recycling fluorite from baotite, magnetite and tailing

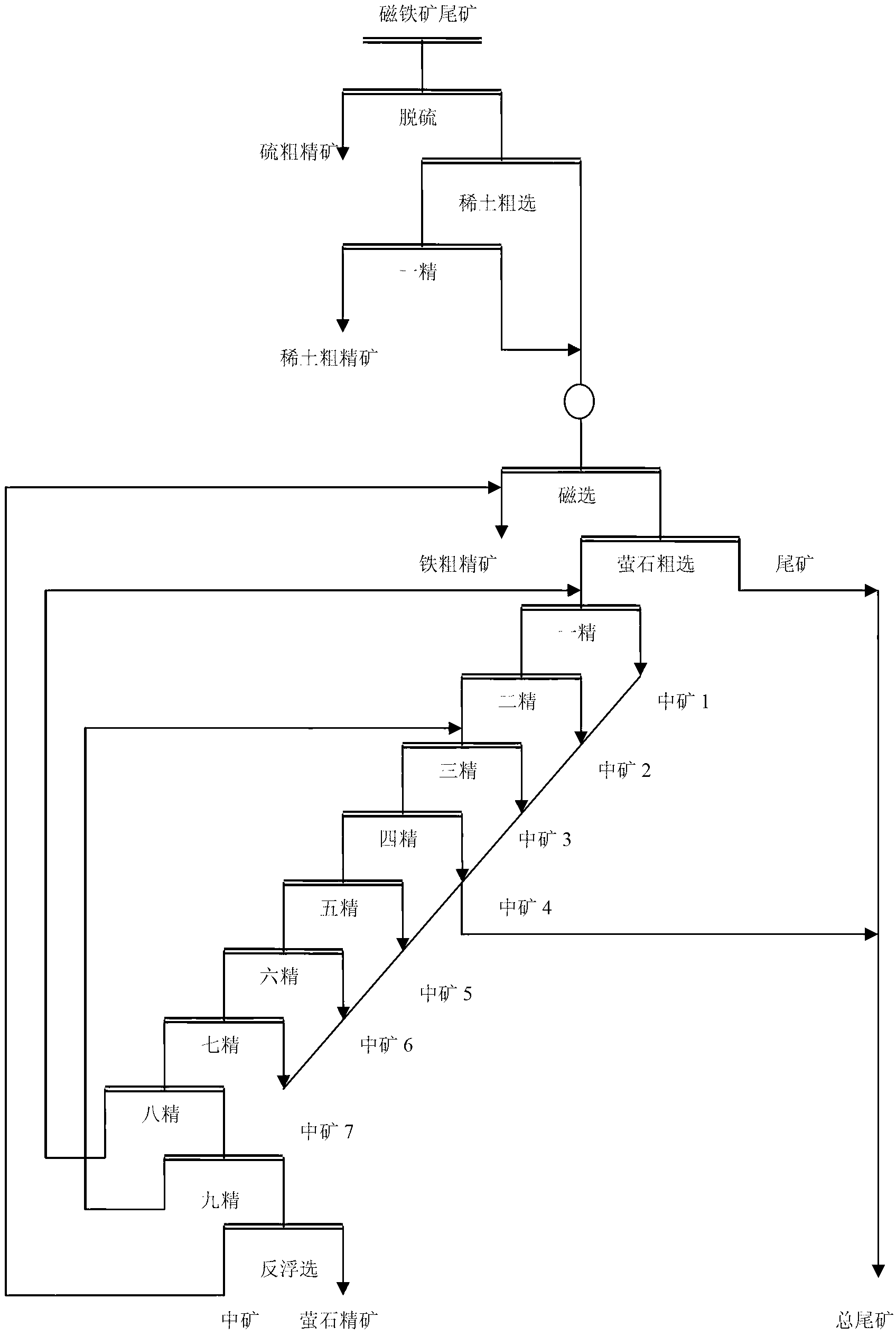

A magnetite and Baotou mine technology, applied in flotation, magnetic separation, solid separation, etc., can solve the problems of difficult separation of fluorite minerals, fine particle size, and ineffective separation of fluorite minerals, etc., achieving strong selectivity, Effective separation and easy handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below with specific examples.

[0020] A beneficiation process for recovering fluorite from magnetite tailings in Baotou Mine mainly includes the following parts:

[0021] 1. Naturally dry, crush and mix the weak magnetic separation tailings in the current process;

[0022] 2. Use the raw materials obtained in the above steps as raw materials for desulfurization flotation. Under natural pH and normal temperature conditions, first add 0.12 kg / t of copper sulfate as an activator for sulfur-containing minerals, and then add 0.05 kg / t of isopropyl xanthate As a collector of sulfur-containing minerals, 0.03kg / t of pine oil was added as a foaming agent at the end, and the sulfur-containing minerals were subjected to rough separation to obtain sulfur crude concentrate and desulfurization tailings with a sulfur grade of 23.36% and a recovery rate of 55.76%. mines, in which desulfurization tailings are used as raw materials for fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com