Preparation method of composite mineral microsphere-based phase change heat storage material

A phase change heat storage material and composite mineral technology, which is applied in the field of preparation of composite mineral microsphere-based phase change heat storage materials, can solve the problems of low heat storage capacity, roughness, easy leakage of phase change materials, etc., so as to improve heat storage. performance, improved dispersion performance, significant heat storage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

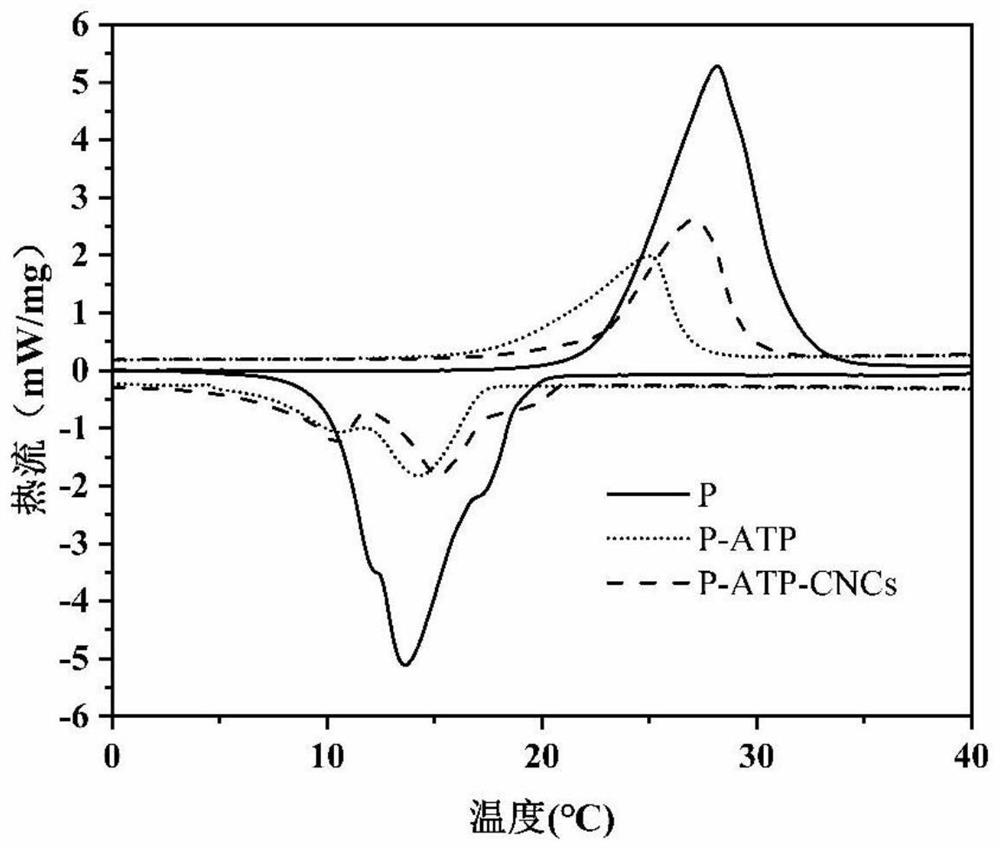

Embodiment 1

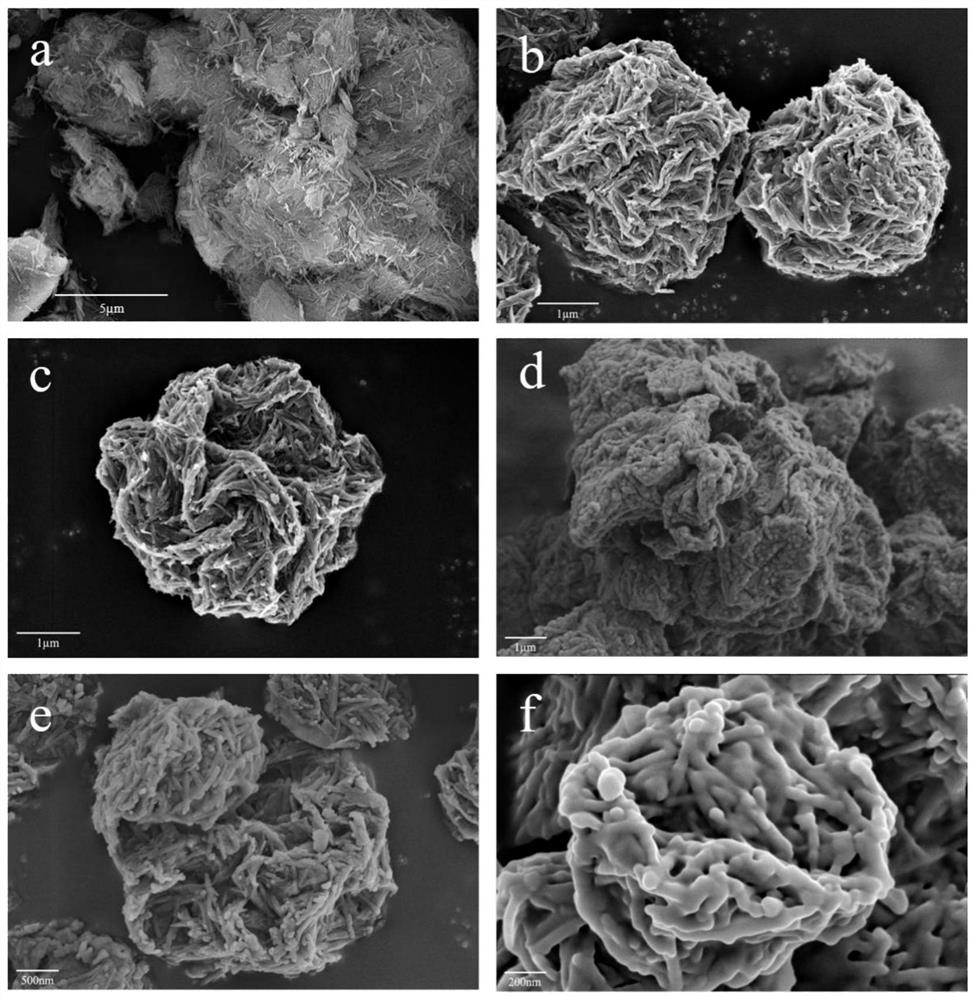

[0048] (1) Put 100 g of embossed stone ore (ATP) in a beaker for 30 min, ultrasonic 30min, stand for a period of time, remove the precipitated impurities, filter, dry, ground, and sieve it to obtain a water washing Fallen stone. Those 30 g of the water washed and placed in a beaker with a 300 ml mass fraction of 4 wt.% Hydrochloric acid solution, a beaker was placed in a constant temperature water bath, stirred, ultrasound, and washing for 60 min. The acid activated groove stone was obtained by purge filtration method.

[0049] (2) Take 3 g of cellulose nanocrystals in 150 ml of deionized water, add 0.75 g sodium sodium phosphate, stirred for 30 min, and the ultrasonic crusher is treated for 30 min to obtain cellulose nanocrystalline solution.

[0050] (3) Take the acid activated section 9 g of 450 ml of deionized water, and 2.25 g of sodium sodium phosphate is added, stirred for 30 min, and the ultrasonic crusher is treated for 30 min to obtain a concave-resistant stone suspensio...

Embodiment 2

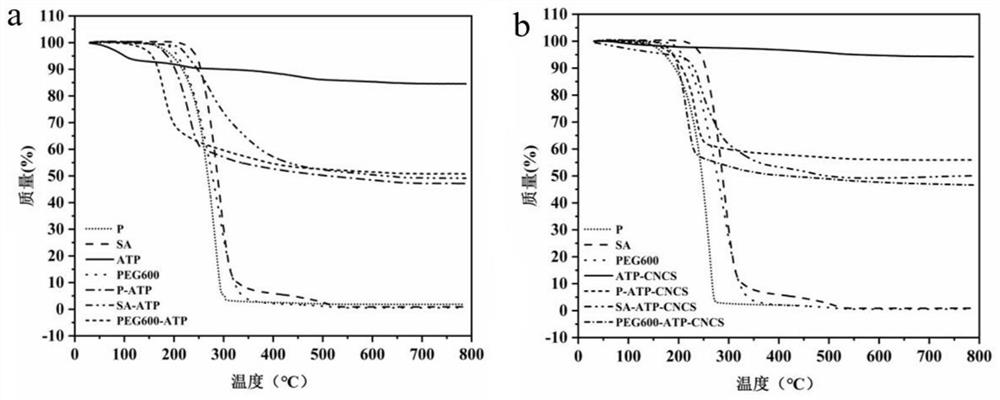

[0054] (1) Preparation method of composite mineral microspheres is in Example 1.

[0055] (2) Weigh 4G composite mineral microspheres and 6 g of stearic acid (SA) to add the filtration bottle, vacuum 20min at room temperature, then vacuum 40min under 90 ° C water, 60 ° C oven heat filtration 12h, Stearic acid - composite mineral microspheres - ATP-CNCs.

Embodiment 3

[0057] (1) Preparation method of composite mineral microspheres is in Example 1.

[0058] (2) Weigh 4 g of composite mineral microspheres and 6 g of Polyethylene glycol 600 (PEG600), in the filtration bottle, vacuuming for 20 min at room temperature, then vacuuming at 90 ° C for 40 min, 60 ° C oven heat filtration 12h, The polyethylene glycol 600-composite mineral microspheres (PEG600-ATP-CNCs) were obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com