Multi-process efficient synergistic retired lithium ion battery positive electrode material recovery method

A technology for lithium-ion batteries and electrode materials, which is applied in the field of recycling cathode materials of decommissioned lithium-ion batteries with high efficiency and coordination in multiple processes, can solve problems such as environmental pollution, increase recycling costs, and reduce metallurgical efficiency of electrode materials, so as to shorten the recycling process, The effect of reducing environmental pollution and reducing the difficulty of purification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with embodiment the present invention will be further described.

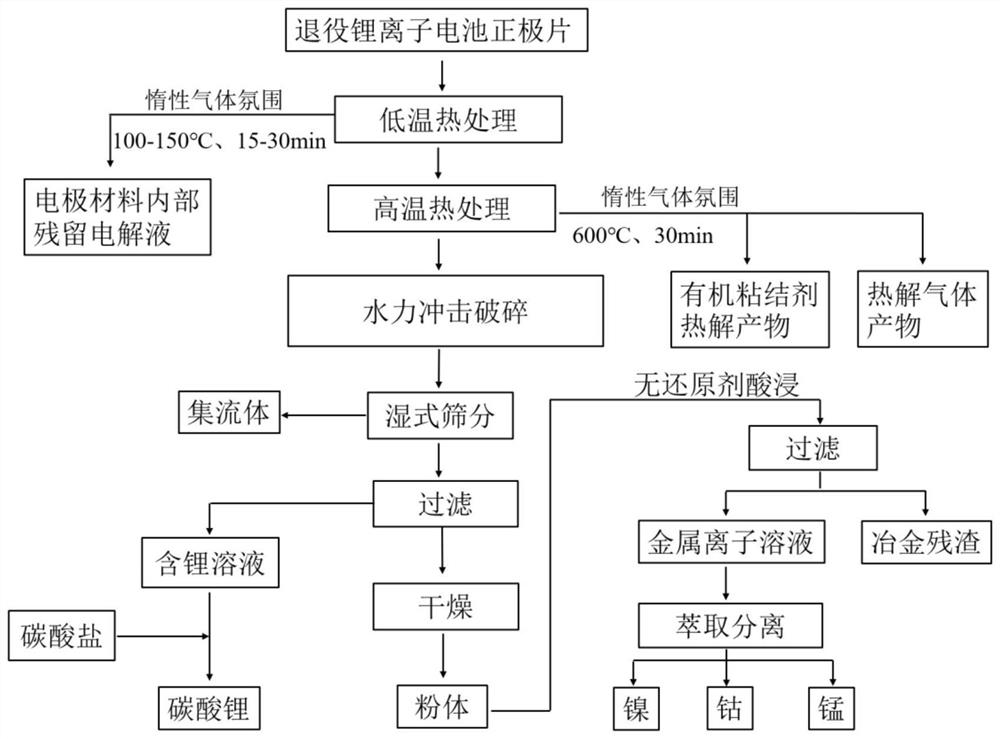

[0027] Such as figure 1 As shown, a method for recovering positive electrode materials of decommissioned lithium-ion batteries of the present invention is characterized in that the steps are as follows:

[0028] Place the positive electrode sheet of the decommissioned lithium-ion battery in the pyrolysis furnace, and fill it with inert gas. First, perform low-temperature pyrolysis to remove the residual electrolyte inside the positive electrode sheet, and then high-temperature pyrolysis to remove the organic binder and use the pyrolysis product as The reduction aid realizes the thermal reduction of high-valent metals in the electrode material of the positive electrode sheet, separates the pyrolysis products of the organic binder and the pyrolysis gas products in the electrode material, obtains the electrode material after pyrolysis, and realizes the removal of organic matter and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com