Method for separating EVA and battery piece in solar module

A technology for solar modules and cells, applied in circuits, photovoltaic power generation, electrical components, etc., can solve problems such as unavailability of available cells, destruction of PN junction metal electrodes and bus bars in solar cells, and poisonous organic solvents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with the embodiments and accompanying drawings. The embodiments are only used to explain the present invention and do not constitute a limitation to the protection scope of the present invention.

[0025] 60 pieces of 340W monocrystalline modules were processed for the "hot spot" scrapped modules found during the operation and maintenance of photovoltaic power plants.

[0026] 1) First of all, the frame removal process is carried out, generally using a special frame removal machine.

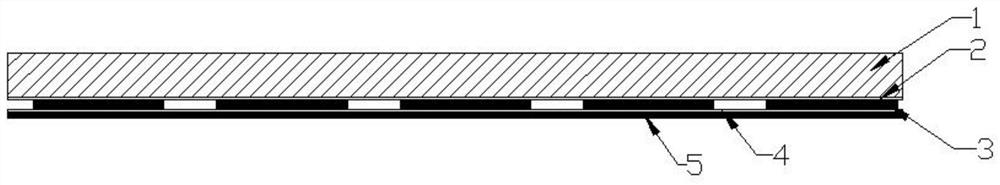

[0027] The structure of the component after removing the aluminum frame is as follows figure 1 As shown, (among them, the battery sheet is wrapped in the upper and lower layers of EVA, and there is no air bubble between the two layers of EVA).

[0028] 2) Heat the frameless component, keep the temperature at about 155°C for 0-40min, the EVA becomes soft, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com