Direct combustion activation process for coal gangue, and geopolymer preparation process

A preparation process, coal gangue technology, applied in the direction of cement production, etc., can solve the problems of low performance of building materials, insignificant social benefits, limited application scenarios, etc., and achieve the goal of improving related performance, improving safety production conditions, and improving reactivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

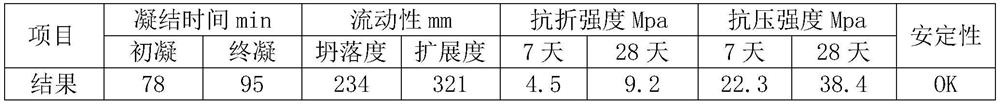

Embodiment 1

[0030] Embodiment one: a kind of coal gangue direct combustion activation process comprises the following steps,

[0031]Step 1, raw material preparation and preliminary treatment, collecting coal gangue with a carbon content of 15%. The collected coal gangue is crushed into particles with a crusher, and the particle size of the crushed coal gangue is less than 15mm;

[0032] Step 2, mid-term treatment, the coal gangue particles from step 1 are sent to the direct-fired heat treatment equipment. The direct-fired heat treatment equipment is equipped with a combustion chamber, a hood at the bottom, and micropores in the hood. The high-pressure air is introduced from the hood, and the high-pressure air is ejected from the micropores of the hood, blowing up the coal gangue particles and turning them over continuously. And feed fuel combustion, the fuel is coke oven gas. A high-temperature regenerator is formed in the combustion chamber, and the temperature in the high-temperature...

Embodiment 2

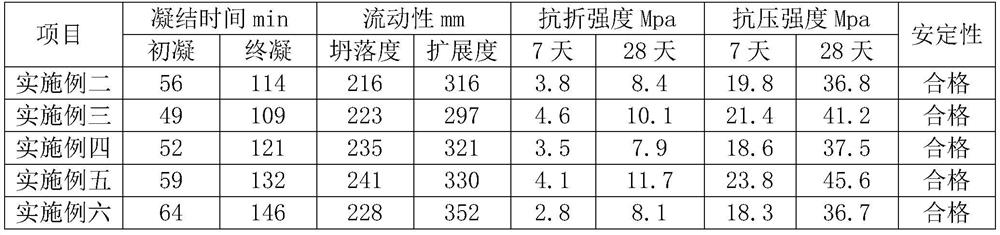

[0038] Embodiment 2: a coal gangue direct combustion activation process, the difference from embodiment 1 is that the carbon content of the coal gangue in step 1 is 8%. In step 2, the fuel is natural gas, the temperature in the high-temperature heat storage tank is maintained in the range of 800-950°C, the treatment time is 5 hours, and the temperature is 725°C when discharging. In step 4, the specific surface area of coal gangue powder obtained by vertical grinding is 500m 2 / kg.

Embodiment 3

[0039] Embodiment 3: The difference from Embodiment 2 is that the fuel is coke oven gas, the temperature in the high-temperature heat storage tank is maintained at 800±50°C for 6 hours, and the final discharge temperature is 705°C. In step 4, the specific surface area after secondary grinding is 520m 2 / kg.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com