Method for extracting beta-glucan from Sparassis crispa

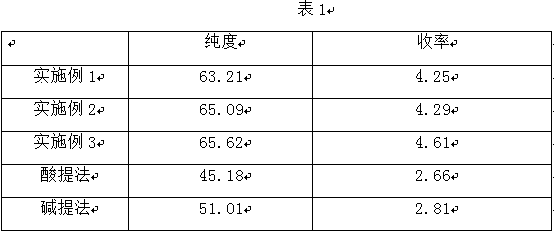

An extraction method, hydrangea technology, applied in the field of dextran extraction, can solve the problems of reagent residue, affecting the quality and safety of health care products and food, and the inability to guarantee the purity and yield of glucan extraction, so as to improve the extraction rate and increase the The effect of purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] S1: Drying, pulverizing and grinding Hydrangea bacteria to obtain superfine powder, which needs to pass through a 80-mesh sieve;

[0026] S2: adding a wall-breaking enzyme agent to the superfine powder, the addition of the cellulase and pectinase are 1200U / g and 800U / g respectively, after ultrasonic enzymolysis, free liquid is obtained;

[0027] S3: Add the free liquid into a high-pressure microwave tank, and perform high-pressure microwave extraction. The microwave power of the high-pressure microwave extraction is 900W, the pressure is 0.8MPa, and the time is 4min. After filtering, the extract is obtained;

[0028] S4: first add amylase to the extract, and perform enzymolysis reaction for 20 minutes; then add protease, and perform enzymolysis for 10 minutes. centrifuged to obtain supernatant;

[0029] S5: Add ammonium sulfate to the supernatant. When adding ammonium sulfate, it needs to be constantly stirred and carried out in a boiling water bath. After it dissolves...

Embodiment 2

[0032] S1: Drying, pulverizing, and grinding Hydrangea bacteria to obtain superfine powder, which needs to pass through a 100-mesh sieve;

[0033] S2: Adding a wall-breaking enzyme agent to the ultrafine powder, the addition amount of the cellulase and pectinase is 1600U / g and 1000U / g respectively, after ultrasonic enzymolysis, a free liquid is obtained;

[0034] S3: Add the free liquid into a high-pressure microwave tank, and perform high-pressure microwave extraction. The microwave power of the high-pressure microwave extraction is 930W, the pressure is 0.9MPa, and the time is 5min. After filtering, the extract is obtained;

[0035] S4: first add amylase to the extract, and perform enzymolysis reaction for 30 minutes; then add protease, and perform enzymolysis for 20 minutes. centrifuged to obtain supernatant;

[0036] S5: add ammonium sulfate to the supernatant, need constant stirring when adding ammonium sulfate, and carry out in boiling water bath, after it dissolves, ad...

Embodiment 3

[0039] S1: Dry, pulverize and grind Hydrangea to obtain superfine powder, which needs to pass through a 100-mesh sieve;

[0040] S2: Adding a wall-breaking enzyme agent to the ultrafine powder, the addition amount of the cellulase and pectinase is 2000U / g and 1300U / g respectively, after ultrasonic enzymolysis, a free liquid is obtained;

[0041] S3: Add the free liquid into a high-pressure microwave tank, and perform high-pressure microwave extraction. The microwave power of the high-pressure microwave extraction is 960W, the pressure is 0.9MPa, and the time is 6min. After filtering, the extract is obtained;

[0042] S4: first add amylase to the extract, and perform enzymolysis reaction for 40 minutes; then add protease, and perform enzymolysis for 30 minutes. centrifuged to obtain supernatant;

[0043] S5: add ammonium sulfate to the supernatant, need constant stirring when adding ammonium sulfate, and carry out in boiling water bath, after it dissolves, add ethanol again, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com