PIP (precursor infiltration and pyrolysis) rapid densification method of SiCf/SiC composite prefab

A technology for composite materials and prefabricated bodies, applied in the field of PIP rapid densification of SiCf/SiC composite material prefabricated bodies, which can solve the problems of long PIP impregnation and cracking preparation period, no consideration of the viscosity of the impregnating solution, and high cost, so as to improve the density, fiber The effect of less damage and less closed pores

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

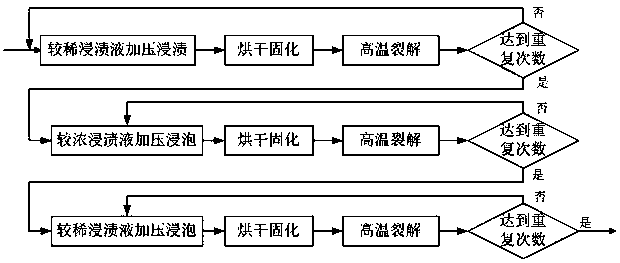

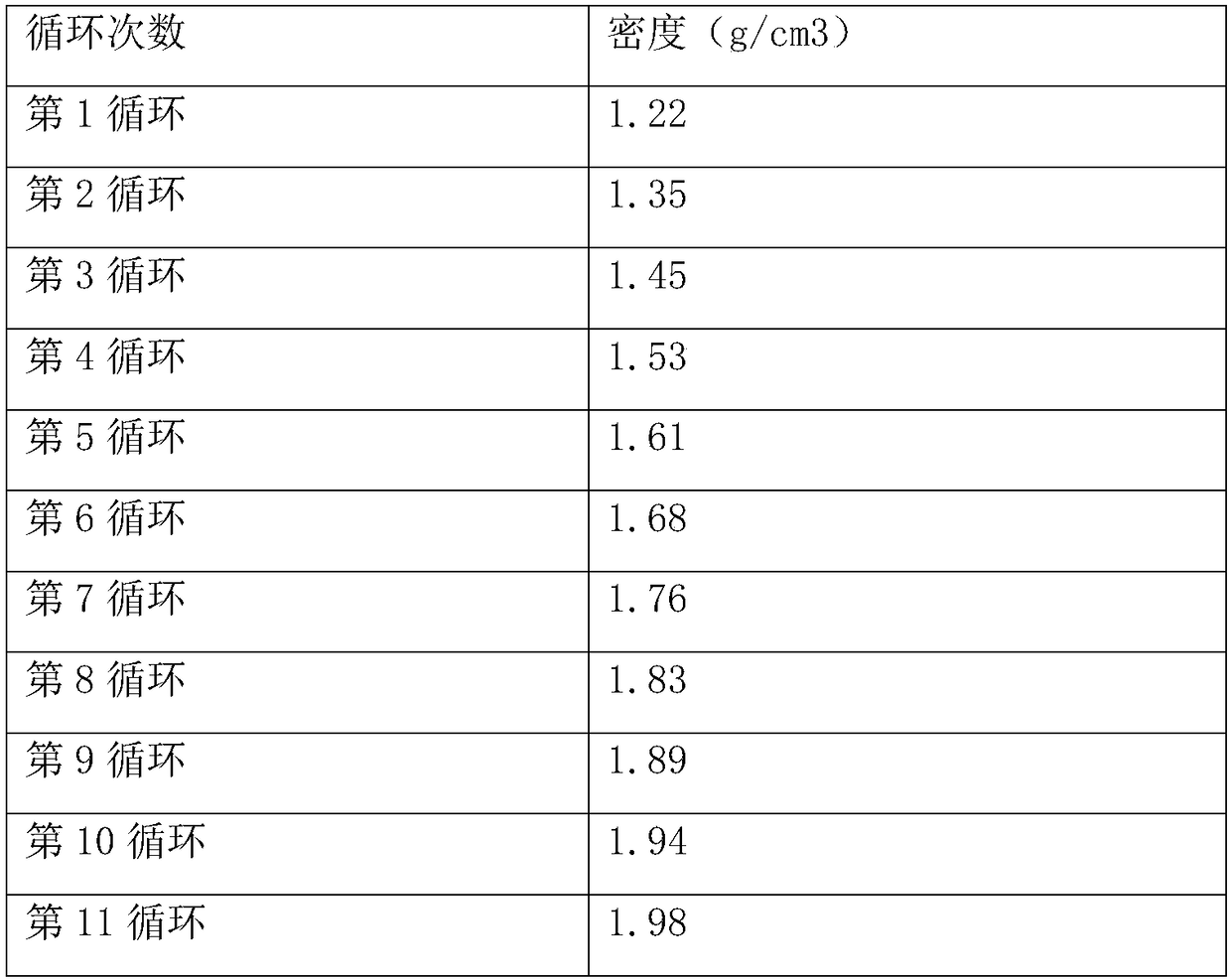

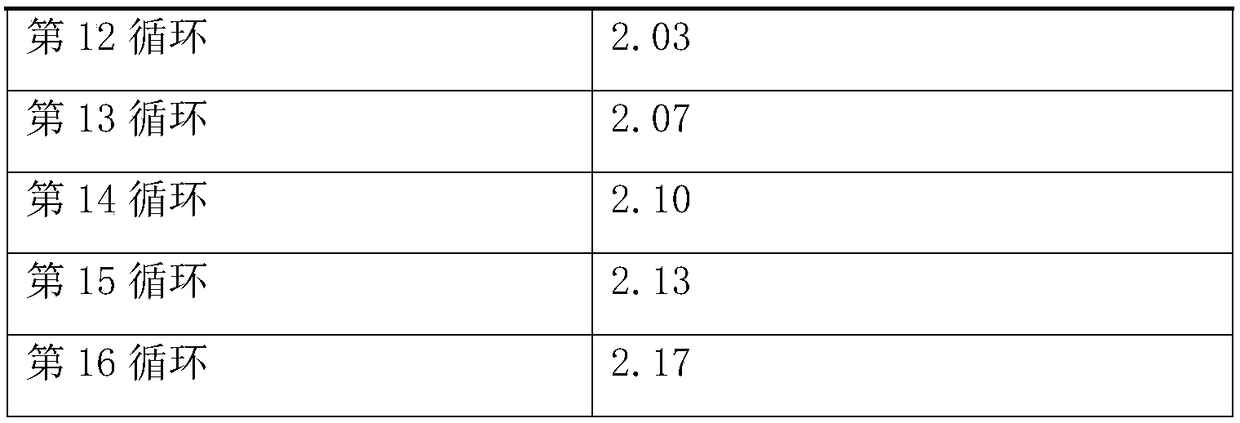

[0035] Specifically, a PIP rapid densification method for SiCf / SiC composite material prefabricated body, take a SiCf / SiC composite material prefabricated body, adopt three-dimensional four-way weaving, the initial density is 1.1g / cm3, and the specification is 300mm×200mm× 20mm. The immersion lysis was carried out according to the method provided by the present invention. The process is divided into the following three stages:

[0036] (1) The process of the first stage is:

[0037] Step 1: First weigh 500g of polycarbosilane with a specification of 200 mesh and 2500g of xylene of analytical grade according to the mass ratio of 1:5, put them all into a beaker to prepare the required impregnation solution, and continuously stir ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com