Carbon fiber precast body liquid phase soaking and densifying method

A technology of carbon fiber prefabrication and carbon fiber, which is applied in the field of C/C composite material molding technology, can solve the problems of increased processing cycle and reduced material impregnation efficiency, and achieve the effects of shortening the densification cycle, improving impregnation efficiency, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

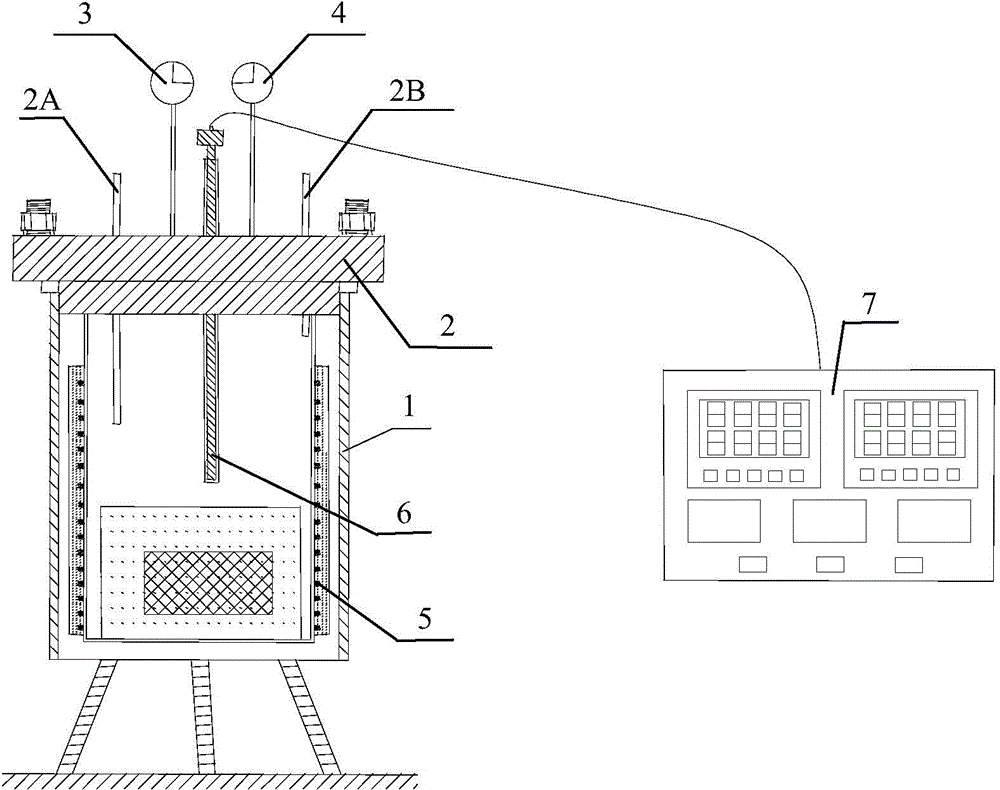

Image

Examples

Embodiment 1

[0022] Embodiment 1 of the present invention includes an impregnation step, a low-temperature treatment step and a high-temperature carbonization step;

[0023] A, impregnating step: comprise following sub-step:

[0024] A1. In the impregnation container, embed the carbon fiber prefabricated body with pitch impregnating agent, then put the impregnation container into the kettle body of the pressurized impregnation equipment, and cover the kettle body to seal the kettle body;

[0025] A2. Connect the nitrogen pressurization system pipeline to the air inlet of the kettle cover, open the air inlet and air outlet valves, fill the kettle body with nitrogen, and discharge the air in the kettle body;

[0026] A3. Close the air inlet and air outlet valves, remove the nitrogen pressurization system pipes on the air inlets, connect the vacuum system pipes to the air inlets of the kettle cover, open the air inlet valves and vacuum gauge valves, and pump the air into the kettle body. Vac...

Embodiment 2

[0033] Embodiment 2 of the present invention includes an impregnation step, a low-temperature treatment step and a high-temperature carbonization step;

[0034] A, impregnating step: comprise following sub-step:

[0035] A1. In the impregnation container, embed the carbon fiber prefabricated body with pitch impregnating agent, then put the impregnation container into the kettle body of the pressurized impregnation equipment, and cover the kettle body to seal the kettle body;

[0036] A2. Connect the nitrogen pressurization system pipeline to the air inlet of the kettle cover, open the air inlet and air outlet valves, fill the kettle body with nitrogen, and discharge the air in the kettle body;

[0037] A3. Close the air inlet and air outlet valves, remove the nitrogen pressurization system pipes on the air inlets, connect the vacuum system pipes to the air inlets of the kettle cover, open the air inlet valves and vacuum gauge valves, and pump the air into the kettle body. Vac...

Embodiment 3

[0044] Embodiment 3 of the present invention includes an impregnation step, a low-temperature treatment step and a high-temperature carbonization step;

[0045] A, impregnating step: comprise following sub-step:

[0046] A1. In the impregnation container, embed the carbon fiber prefabricated body with pitch impregnating agent, then put the impregnation container into the kettle body of the pressurized impregnation equipment, and cover the kettle body to seal the kettle body;

[0047] A2. Connect the nitrogen pressurization system pipeline to the air inlet of the kettle cover, open the air inlet and air outlet valves, fill the kettle body with nitrogen, and discharge the air in the kettle body;

[0048] A3. Close the air inlet and air outlet valves, remove the nitrogen pressurization system pipes on the air inlets, connect the vacuum system pipes to the air inlets of the kettle cover, open the air inlet valves and vacuum gauge valves, and pump the air into the kettle body. Vacuu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com