Preparation method of low-modulus and high-toughness silver-containing titanium alloy

A titanium alloy and low-modulus technology, which is applied in the field of preparation of low-modulus, high-strength and tough silver-containing titanium alloys, can solve the problems of alloy tensile plasticity reduction, avoid the influence of elastic modulus, avoid the segregation of Ag elements, and improve The effect of dispersion uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] This embodiment includes the following steps:

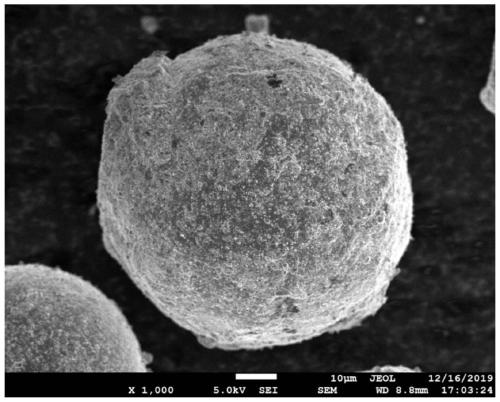

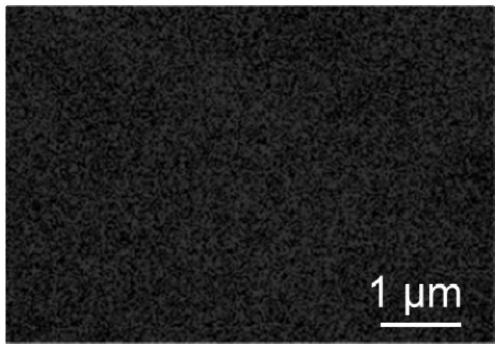

[0026] Step 1. Preparation of mixed powder: 199.2g of Ti-3Zr-2Sn-3Mo-25Nb titanium alloy powder was mixed with 0.8g nano-Ag powder by low-energy ball milling to obtain a mixed powder; the average particle size of the nano-Ag powder was 6nm, Ti - The particle size of the 3Zr-2Sn-3Mo-25Nb titanium alloy powder is 53 μm to 75 μm, the ball-to-material ratio of the low-energy ball mill is 3:1, the rotation speed is 200 rpm, and the ball milling time is 1 h;

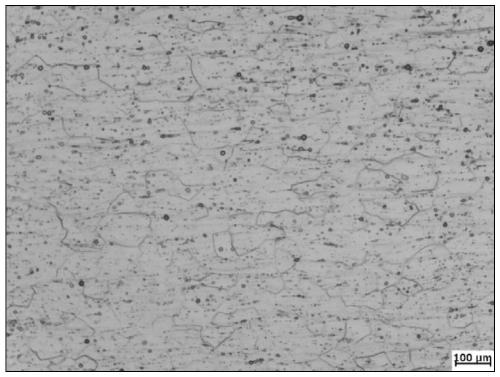

[0027] Step 2, sintering and forming: sintering and forming the mixed powder obtained in step 1 to obtain a silver-containing titanium-based sintered compact; the pressure used in the sintering and forming is 35 MPa, the temperature is 900 ° C, and the holding time is 1 min;

[0028] Step 3, preparation and molding: hot rolling the silver-containing titanium-based sintered billet obtained in step 2 to obtain a silver-containing titanium alloy plate; the hot-rolling process...

Embodiment 2

[0041] This embodiment includes the following steps:

[0042] Step 1. Preparation of mixed powder: 198.2g of Ti-3Zr-2Sn-3Mo-25Nb titanium alloy powder and 1.8g of nano-Ag powder were mixed by low-energy ball milling to obtain a mixed powder; the average particle size of the nano-Ag powder was 6nm, Ti - The particle size of the 3Zr-2Sn-3Mo-25Nb titanium alloy powder is 53 μm to 75 μm, the ball-to-material ratio of the low-energy ball mill is 3:1, the rotation speed is 200 rpm, and the ball milling time is 1 h;

[0043] Step 2, sintering and forming: sintering and forming the mixed powder obtained in step 1 to obtain a silver-containing titanium-based sintered compact; the pressure used in the sintering and forming is 45 MPa, the temperature is 1000 ° C, and the holding time is 3 minutes;

[0044] Step 3, preparation and molding: hot rolling the silver-containing titanium-based sintered billet obtained in step 2 to obtain a silver-containing titanium alloy plate; the hot-rolling...

Embodiment 3

[0046] This embodiment includes the following steps:

[0047] Step 1. Preparation of mixed powder: 198.7g of Ti-3Zr-2Sn-3Mo-25Nb titanium alloy powder and 1.3g of nano-Ag powder were mixed by low-energy ball milling to obtain a mixed powder; the average particle size of the nano-Ag powder was 6nm, Ti - The particle size of the 3Zr-2Sn-3Mo-25Nb titanium alloy powder is 53 μm to 75 μm, the ball-to-material ratio of the low-energy ball mill is 3:1, the rotation speed is 200 rpm, and the ball milling time is 1 h;

[0048] Step 2, sintering and forming: sintering and forming the mixed powder obtained in step 1 to obtain a silver-containing titanium-based sintered compact; the pressure used in the sintering and forming is 40 MPa, the temperature is 950 ° C, and the holding time is 2 minutes;

[0049] Step 3, preparation and molding: hot rolling the silver-containing titanium-based sintered billet obtained in step 2 to obtain a silver-containing titanium alloy plate; the hot-rolling ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com