Wind and gas control system for fuel gas stove

A control system and gas stove technology, applied in the direction of burner, combustion method, heating fuel, etc., can solve problems such as burns and scalds, and achieve the effects of avoiding potential safety hazards, convenient use, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] Below in conjunction with embodiment technical solution of the present invention is made more specific description:

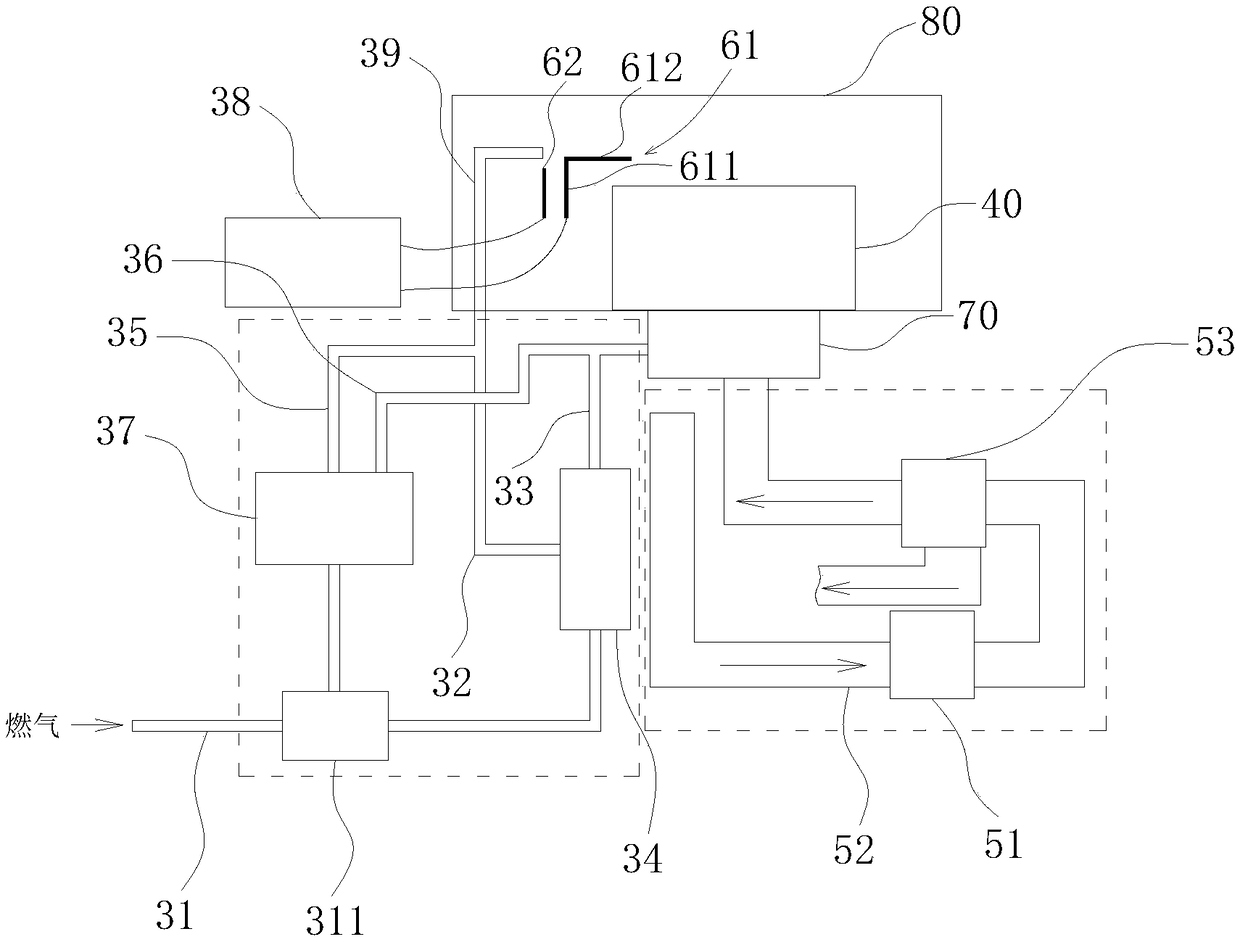

[0044] Such as figure 1 As shown: the present invention includes a gas circuit unit, and the gas circuit unit includes a main gas circuit 31 and an automatic ignition gas circuit unit and a manual ignition gas circuit unit respectively communicated with the general gas circuit 31 . The main gas circuit 31 is provided with a gas main valve 311 for switching gas to the automatic ignition gas circuit unit or the manual ignition gas circuit unit.

[0045] 1-Manual ignition gas circuit unit

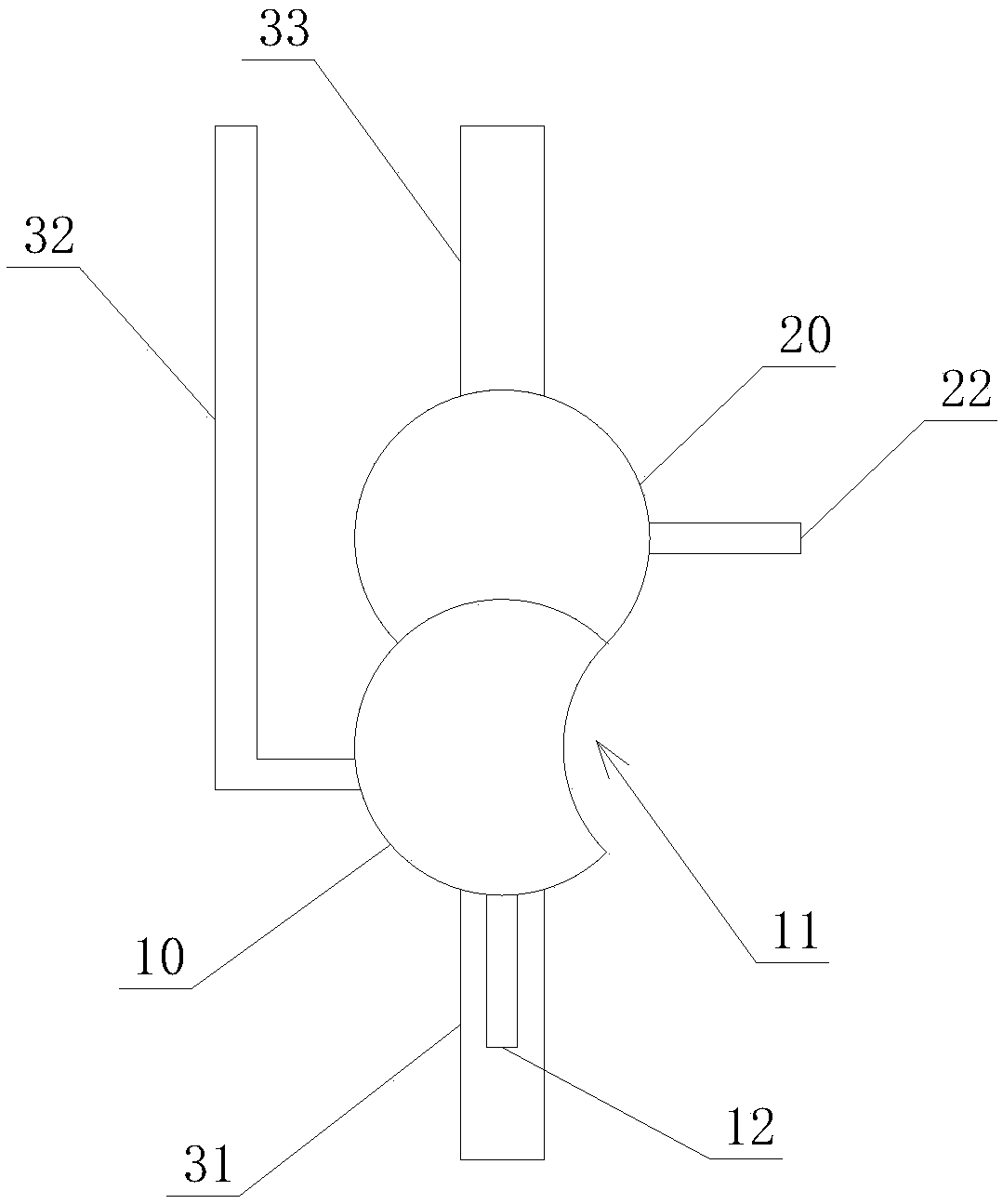

[0046] Such as figure 2 As shown: when the second notch 21 is at the 6 o'clock position directly below the second turntable, and when the first notch 11 is at the 3 o'clock position of the first turntable, the permanent flame gas circuit valve And the main fire gas path valve is in the initial closed state, the edge of the first turntable 10 coincides with the second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com