Motor controller and controlling method thereof

A motor controller and core control technology, applied in the direction of motor speed or torque control, control system, electrical components, etc., can solve problems such as motor controller overcurrent, damage to electrical equipment, and controller not working properly. Achieve the effect of protecting the motor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention is further described below.

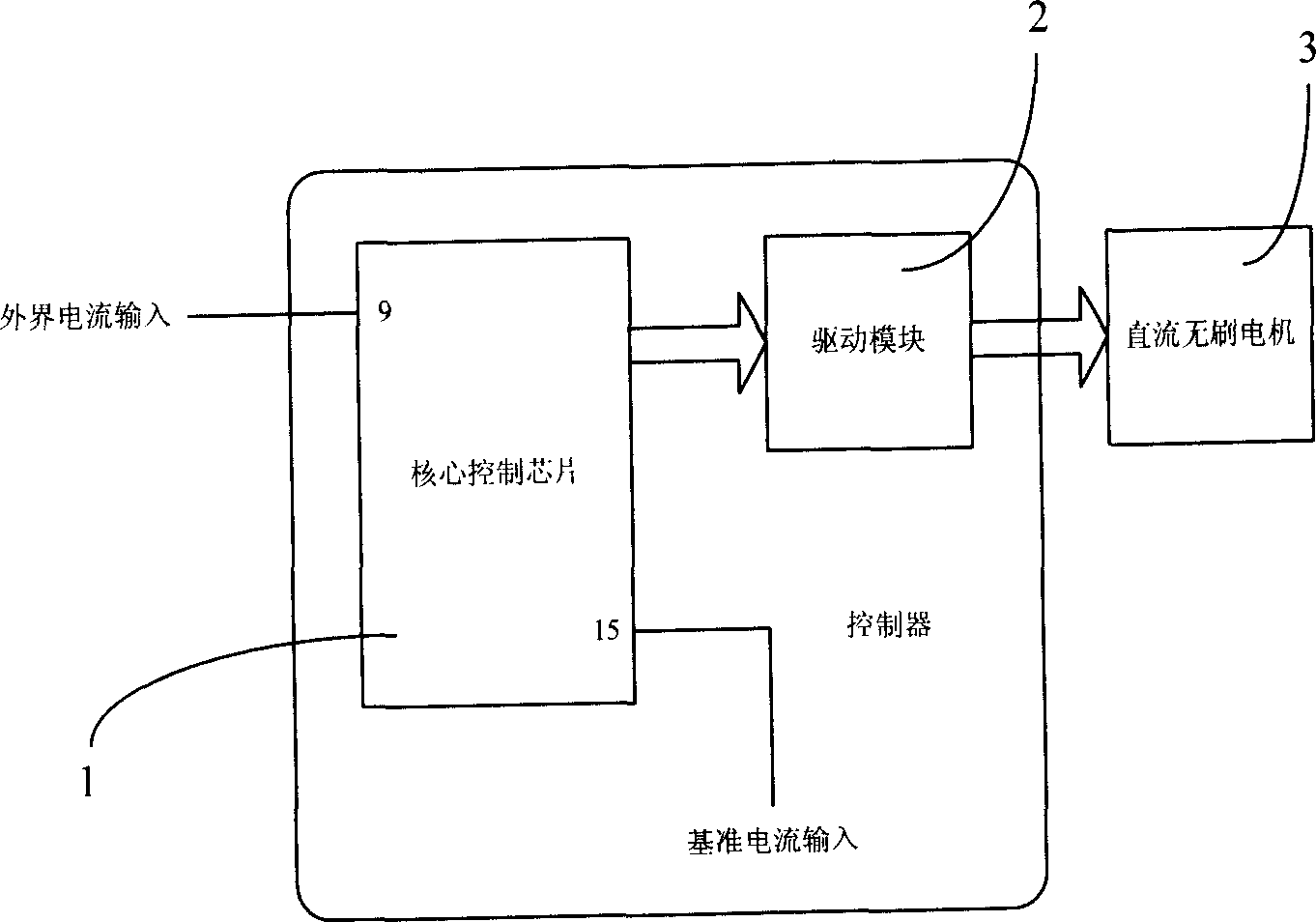

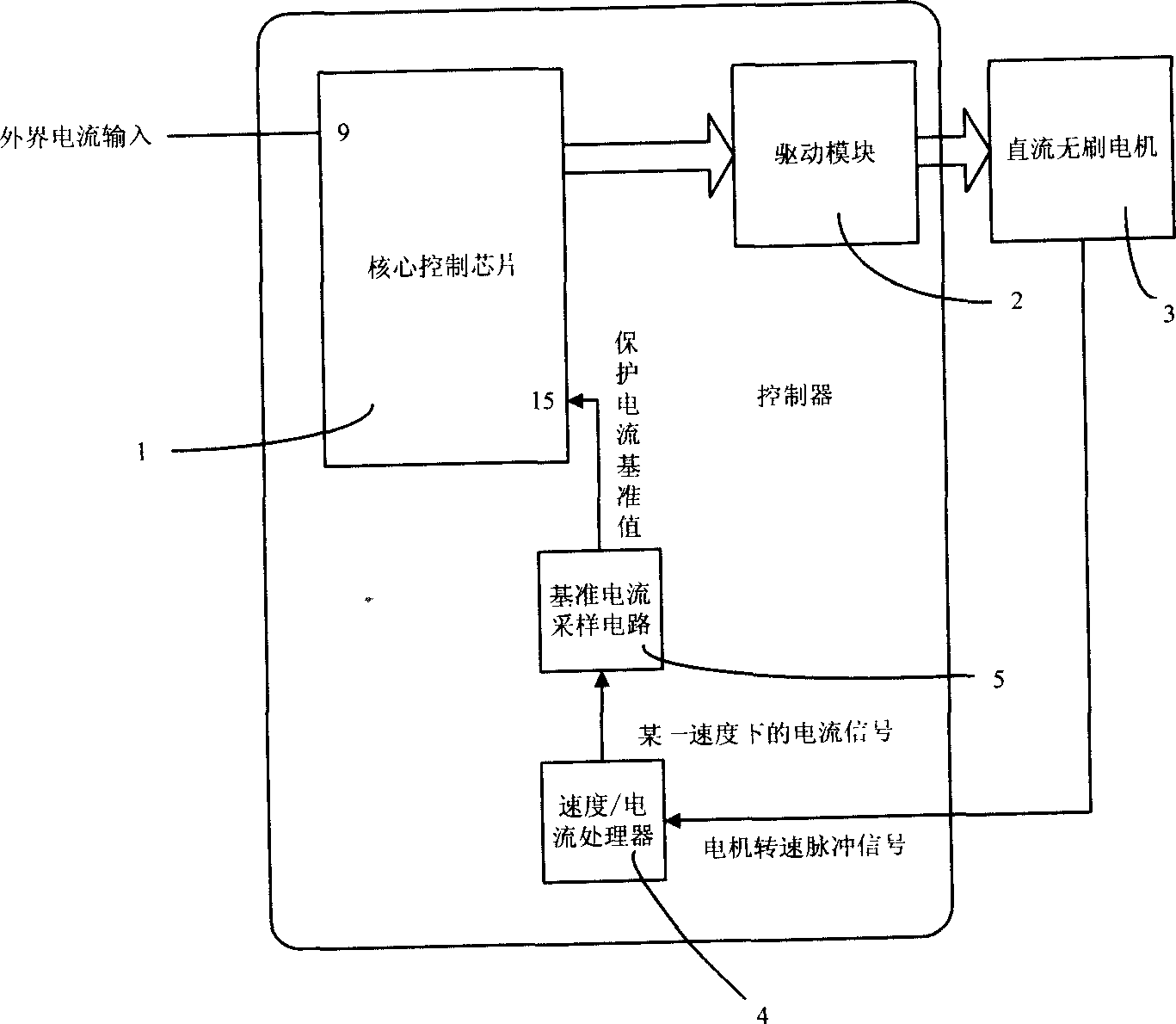

[0029] A motor controller provided by the present invention is used for overcurrent safety protection of brushless DC motors of electric vehicles, please refer to figure 1 , the motor controller includes: a core control chip 1 and a drive module 2, and the output of the core control chip 1 is connected to the drive module 2 to control it, and the drive module 2 is connected to the motor 3 to output drive.

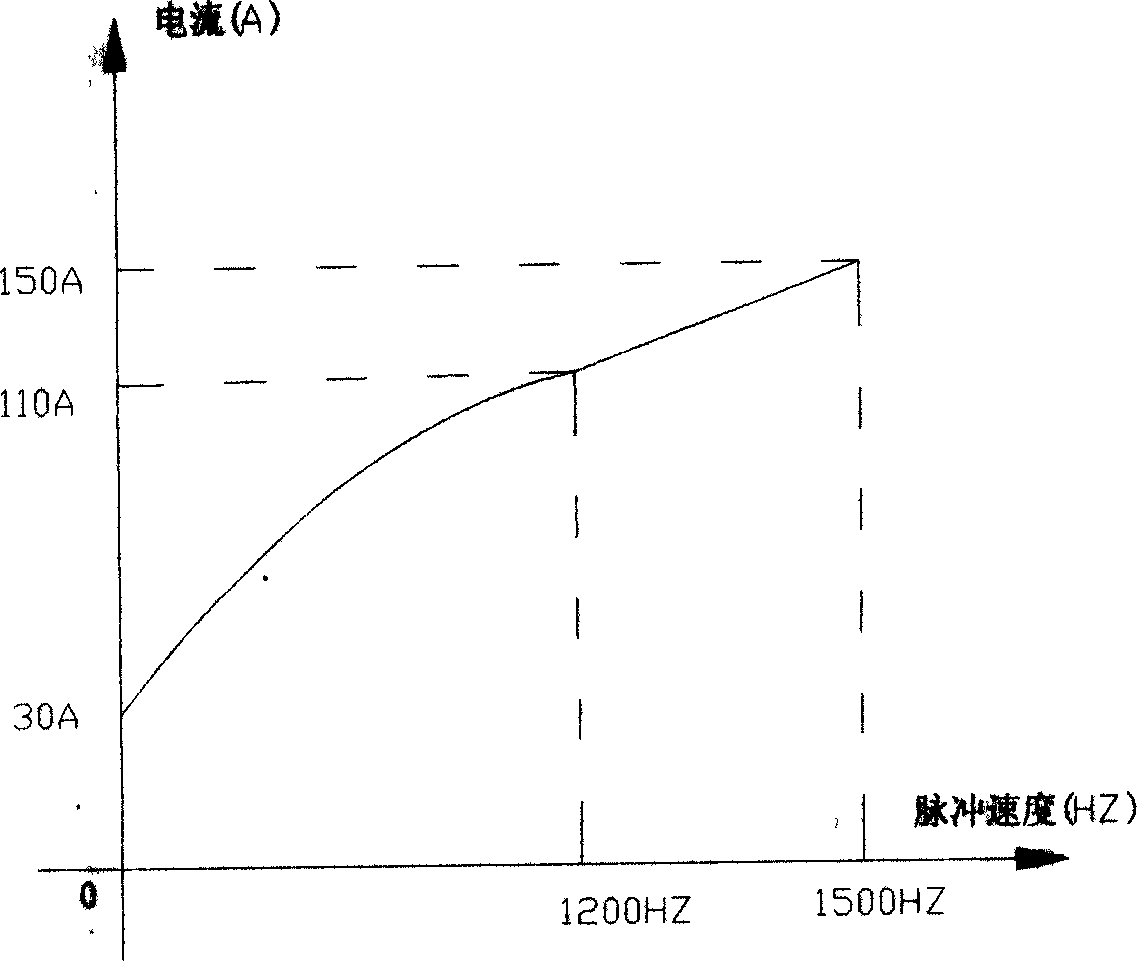

[0030] The core control chip 1 adopts a model of MC33035, which is specially used for motor control integrated circuits of DC brushless motors. The integrated circuit has a comparator inside, and two different current values can be input through pin 9 and pin 15 for comparison and judgment. Here, the 15th pin is the reference protection current input pin (Current Sense Inverting Input), which is the preset protection current reference value. After testing, the reference protection current is usually set to a fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com