Forced-cooling high-power LED lamp

A technology of LED lamps and high power, which is applied to lighting and heating equipment, cooling/heating devices of lighting devices, lighting devices, etc. The effect of power consumption and efficient heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment l

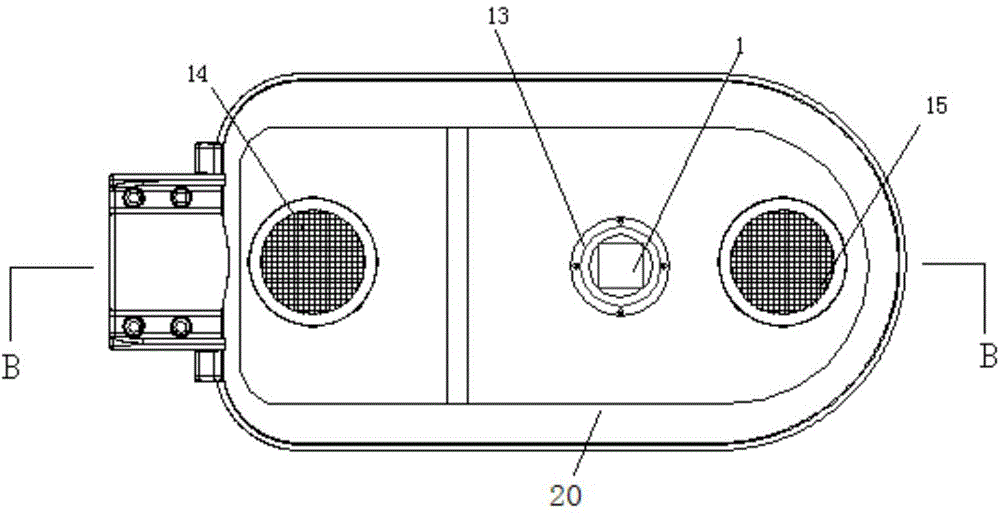

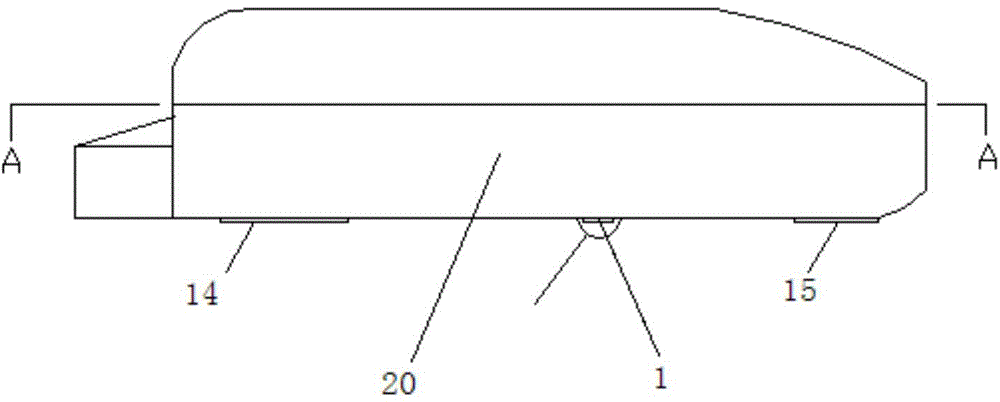

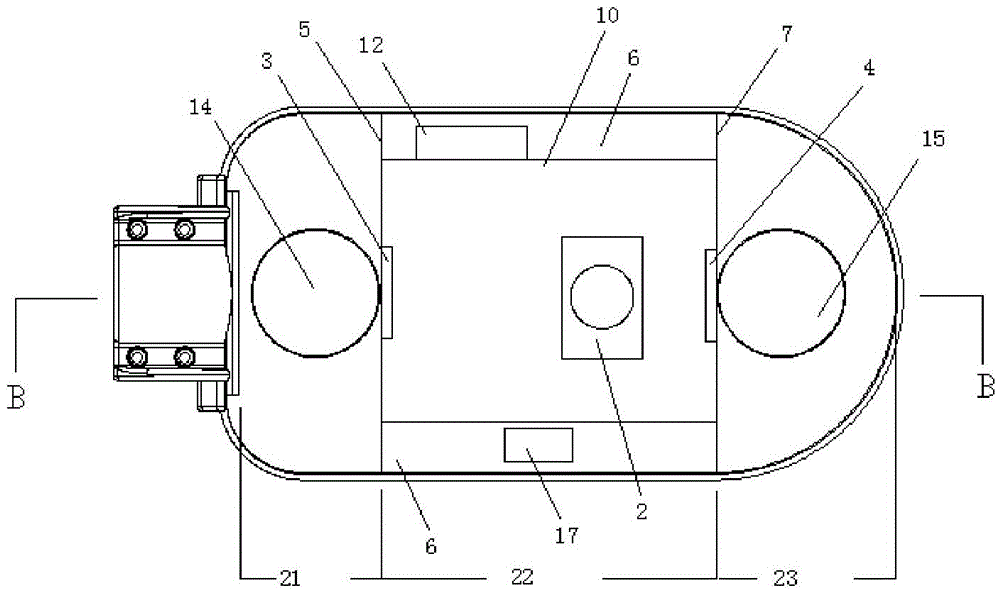

[0055] 100W rainproof LED street light for single fin heat pipe radiator, according to Picture 1-1 , Figure 1-2 , Figure 1-3 , Figure 1-4 , Figure 1-5 shown.

[0056] A forced heat dissipation high-power LED lamp, comprising a lamp housing 20, an air intake area 21, a heat dissipation area 22, and an exhaust area 23, the air intake area 21, the heat dissipation area 22, and the exhaust area 23 are assembled in the lamp housing 20; An air inlet partition 5 is provided between the area 21 and the heat dissipation area 22, and the air inlet partition 5 is provided with an air inlet partition air guide hole 8; an exhaust partition is provided between the heat dissipation area 21 and the exhaust area 23 7. The air exhaust partition 7 is provided with the air guide hole 9 of the exhaust partition; the air intake area 21 includes the air intake fan 3, the air intake hole 14 of the lamp housing, the overflow hole 11, the rain blocking plate 16, the insect net 24 and the resist...

Embodiment 2

[0060] For parallel connection of 2 fin radiators 200W rainproof LED street light, according to diagram 2-1 , Figure 2-2 , Figure 2-3 , Figure 2-4 , Figure 2-5 shown.

[0061] The difference from Embodiment 1 is that the cross section of the air duct 10 is circular;

[0062] The air duct 10, the air inlet partition 5, the exhaust partition 7, the inlet fan 3, the exhaust wind 4, and the outer surface of the finned heat pipe radiator 2 all have a nano-ceramic non-stick coating layer;

[0063] Air duct 10 adopts copper plate to make.

[0064] The air intake fan 3 is installed on the outside of the air intake partition 5 of the air duct 10; the exhaust fan 4 is installed on the outside of the exhaust partition 7 of the air duct 10;

[0065] The finned heat pipe radiators 2 are connected in parallel in the lamp housing 20 , and each finned heat pipe radiator 2 is independent of each other.

Embodiment 3

[0067] For 2 fin radiators connected in series 200W rainproof LED street light, according to Figure 3-1 , Figure 3-2 , Figure 3-3 , Figure 3-4 , Figure 3-5 shown.

[0068] The difference from Embodiment 1 is that the cross section of the air duct 10 is circular;

[0069] Air duct 10, air intake partition 5, exhaust partition 7, intake fan 3, exhaust air 4, and finned heat pipe radiator 2 are all provided with polytetrafluoroethylene non-stick coating layer on the outer surface

[0070] Air duct 10 adopts iron plate to make.

[0071] The finned heat pipe radiators 2 are connected in series in the lamp housing 20 , and each finned heat pipe radiator 2 is independent of each other.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com