Coal ball stove

A technology of briquette furnace and furnace shell, which is applied in the field of intelligent briquette furnace, can solve the problems that the diameter of the briquette furnace cannot be too large, inconvenient, broken, etc., and achieve the effects of shortening the combustion time, saving labor and reducing energy waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

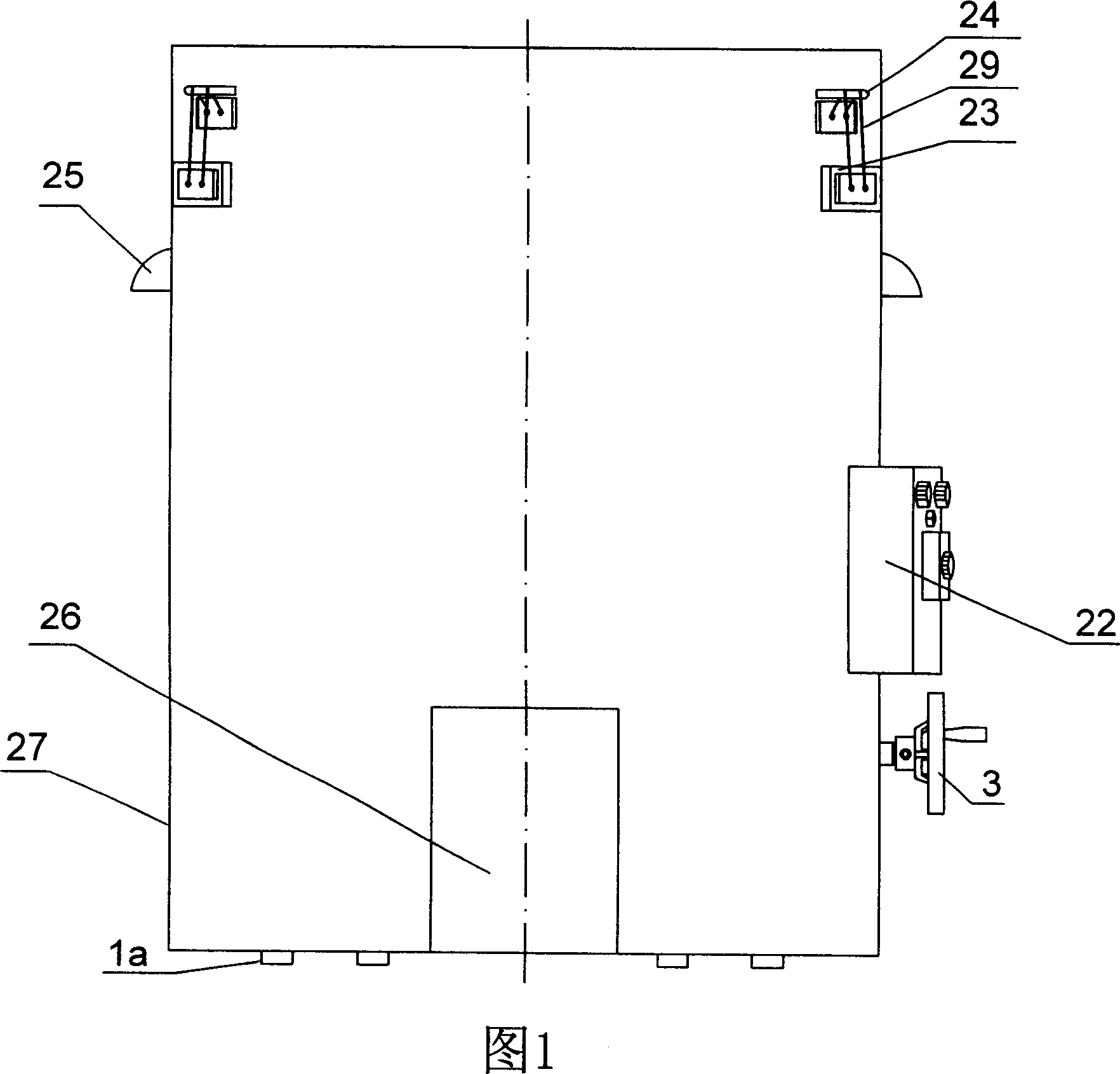

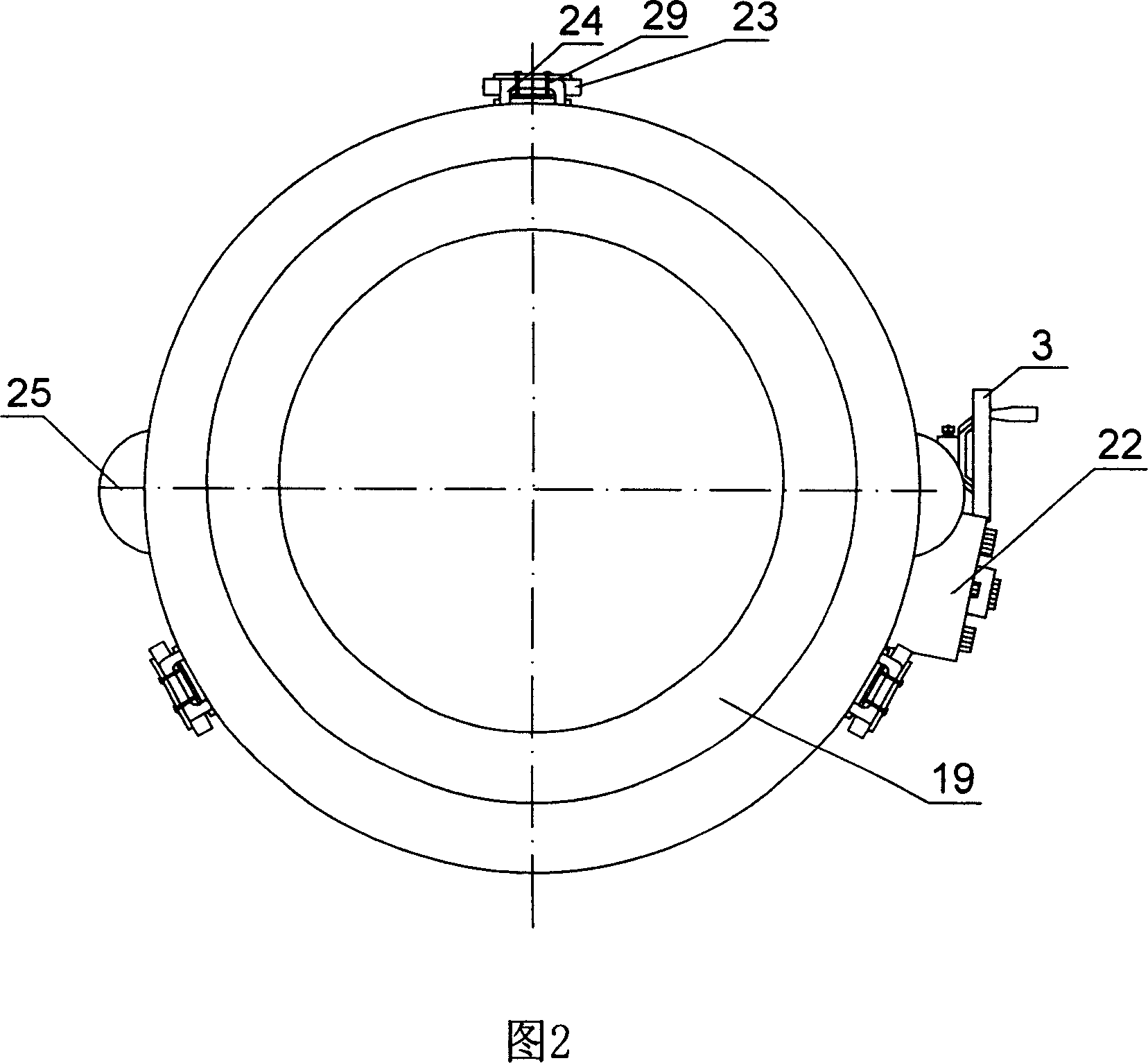

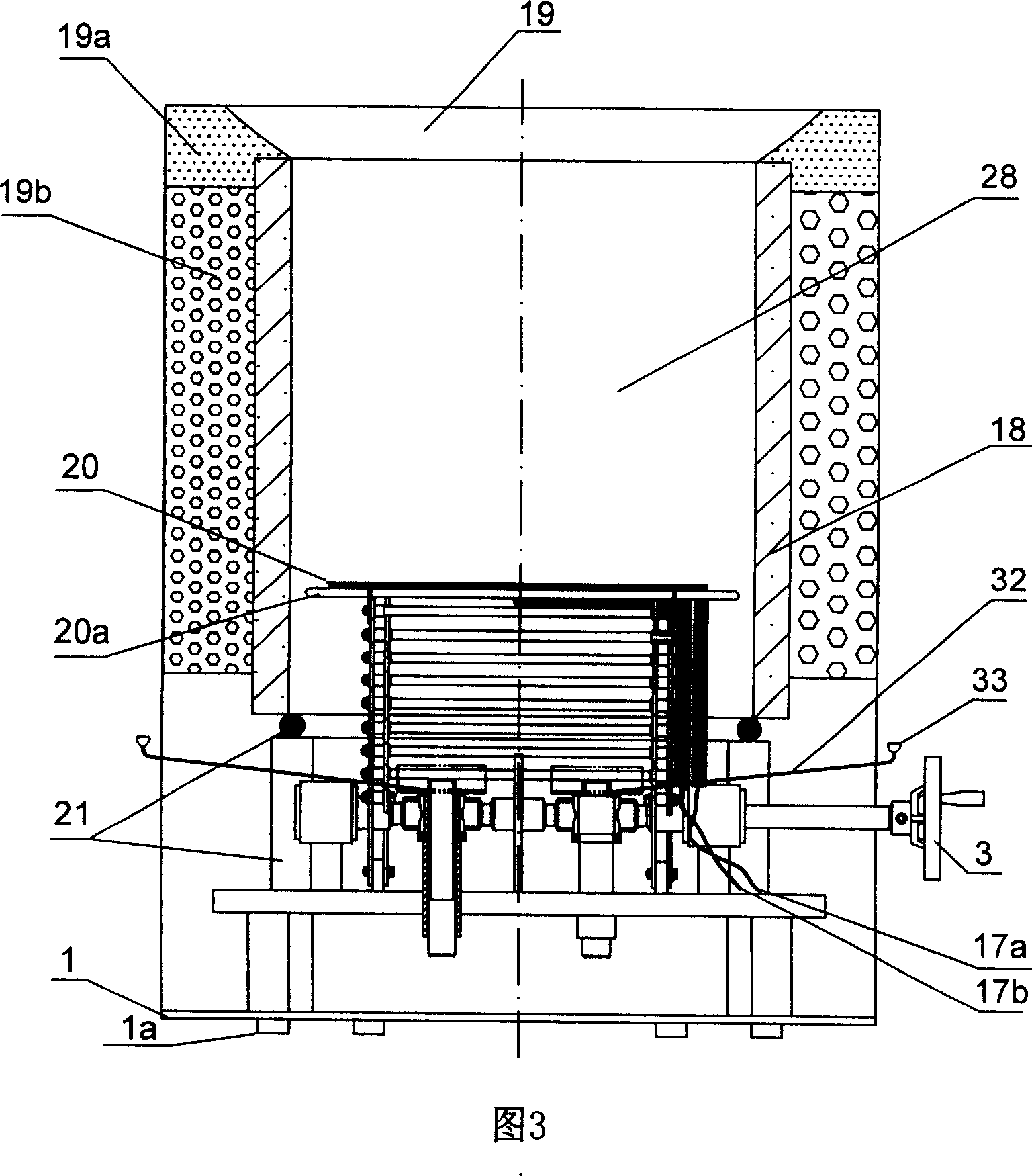

[0032] As shown in Figures 1 to 7, the intelligent briquette furnace includes a furnace shell 27, and the furnace shell 27 is equipped with a furnace core 18, a thermal insulation filler 19b, a furnace core support frame 21, an electric heating tube 20, an electric heating tube fixing frame 20a, and a furnace floor 1 A furnace foot 1a is installed under the furnace bottom plate 1, and an electrical control device 22 is installed outside the furnace shell 27. The electric heating tube 20 and the electrical control device 22 are connected by an input high-temperature resistant wire 17a and an output high-temperature resistant wire 17b, which is characterized in that the intelligent The briquette furnace also includes a stroke lifter 30, which is arranged between the bottom of the furnace core 18 and the furnace floor 1, and the electric heating tube 20 and the electric heating tube fixing frame 20a are placed on the stroke lifter 30.

[0033] Referring to Figures 5 to 7, the stro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com