Efficient energy-saving heating furnace

A high-efficiency energy-saving heating furnace technology, which is applied to household furnaces/stoves, furnaces/stoves with hot water devices, heating methods, etc., can solve the problems of easy heat loss, large emissions of gas pollutants, and poor heat collection effects, etc. problems, to avoid heat waste, reduce pollutant emissions, and improve heat utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

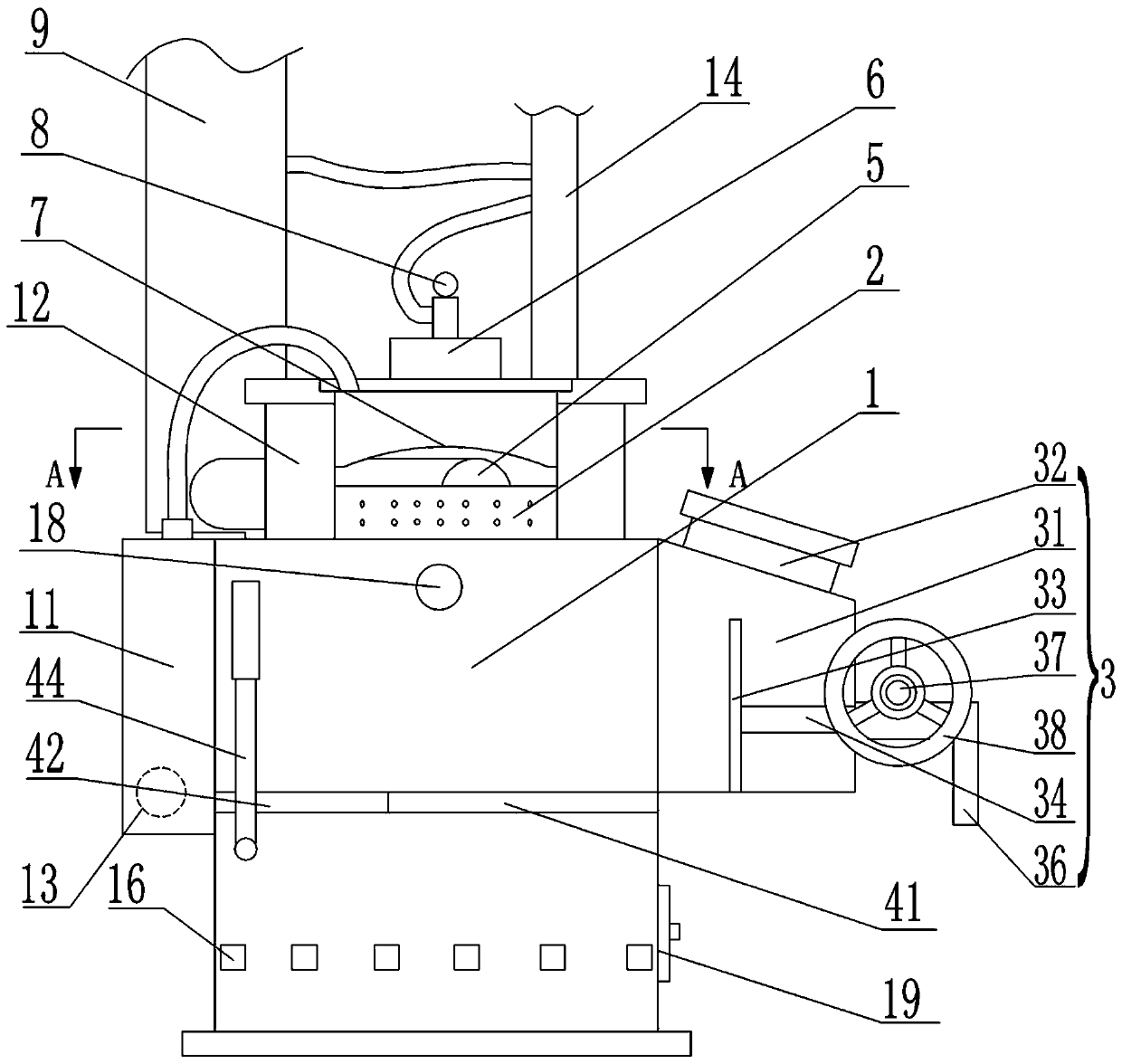

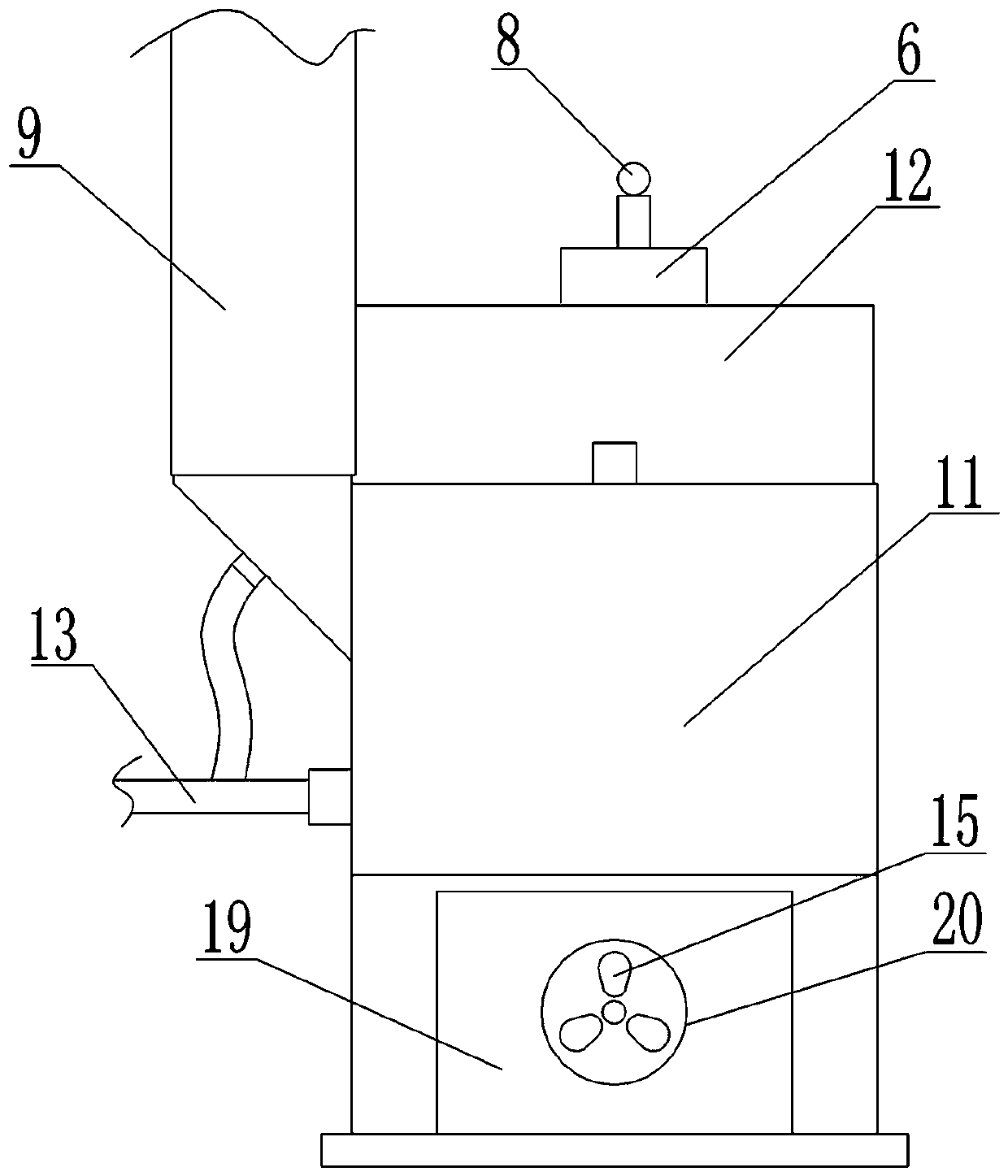

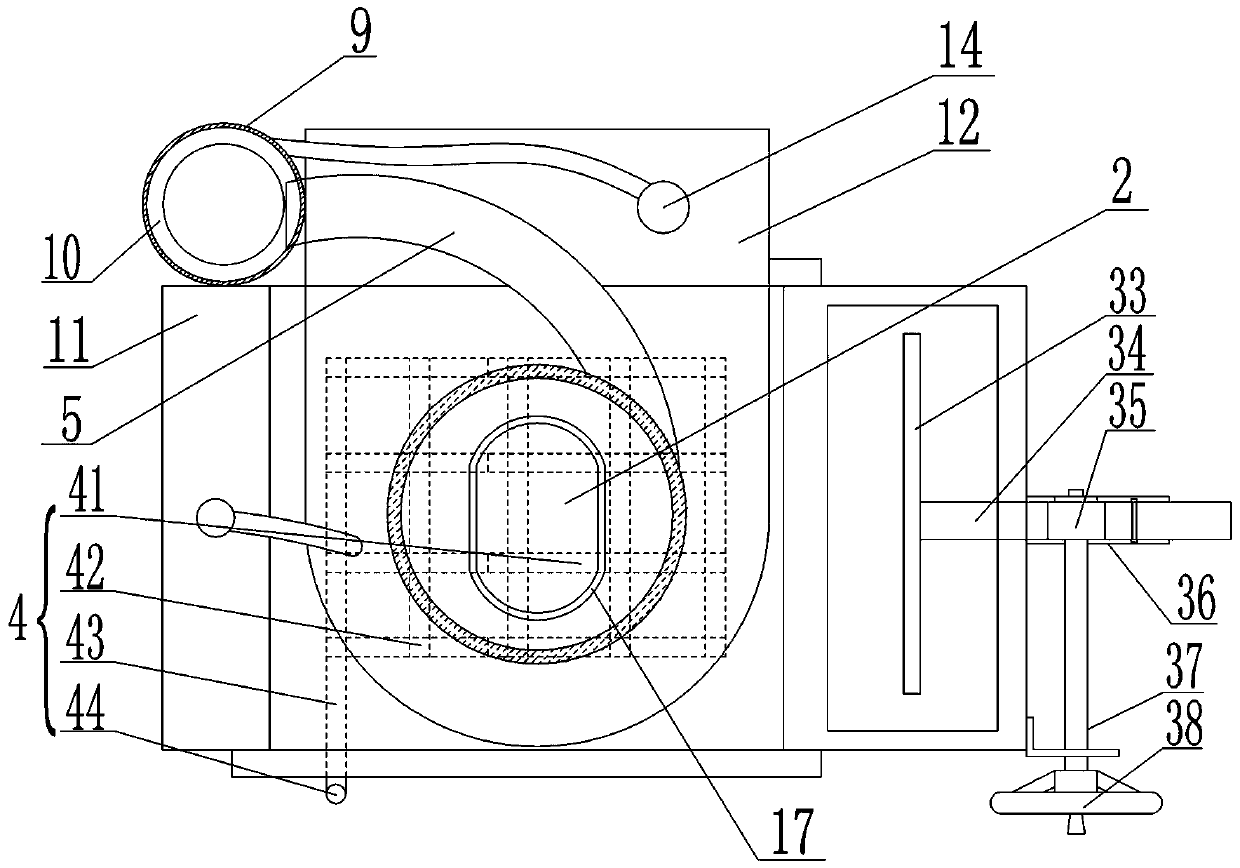

[0035] Embodiment High-efficiency and energy-saving heating furnace

[0036] This example Figure 1-Figure 4 As shown, a high-efficiency energy-saving heating furnace includes a furnace body 1, and the upper part of the furnace body 1 is a combustion chamber 2 for storing fuel and burning the fuel. The cross section of the flame port of the combustion chamber is: the middle It is rectangular, with semicircular ends, which is more conducive to the gathering of flames, making the fuel burn more fully and reducing CO emissions. The two corners of the inner wall of the combustion chamber 2 of the furnace body 1 are arc-shaped, which can effectively reflect flames and gather heat. Above the combustion chamber 2 is provided a hot water collection bag 6 for sealing the combustion chamber 2 , and the hot water collection bag 6 is fastened on the furnace body 1 to seal the opening of the combustion chamber 2 . The hot water collection bag 6 is provided with a cavity for storing circu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com