Semi-automatic annular winding machine protection device

A protection device and winding machine technology, which is applied in coil manufacturing and other directions, can solve the problems of mechanical accident injury, finger entry, limited space, etc., and achieve the effect of simple overall structure, avoiding biting injuries, and convenient and quick maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

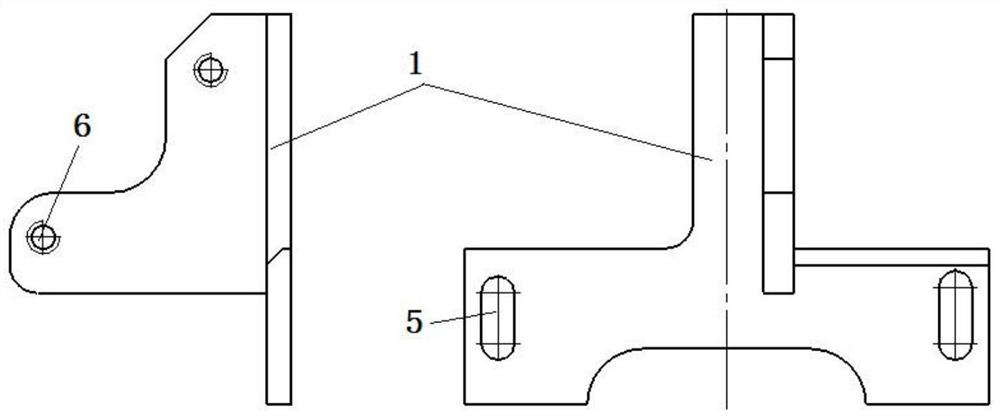

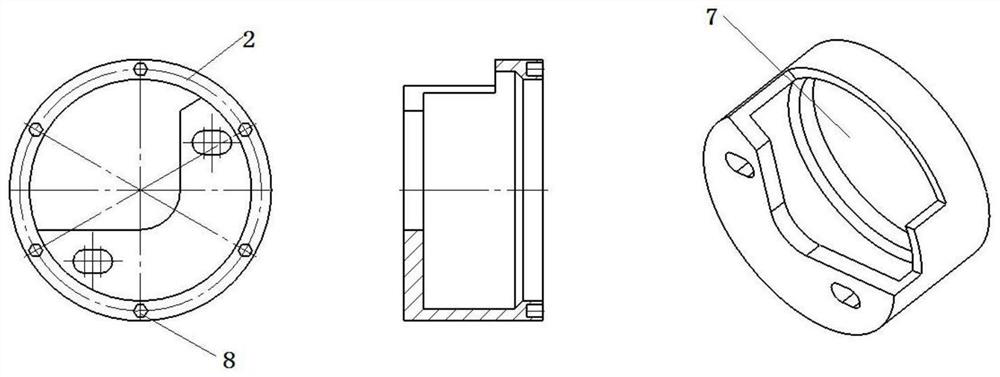

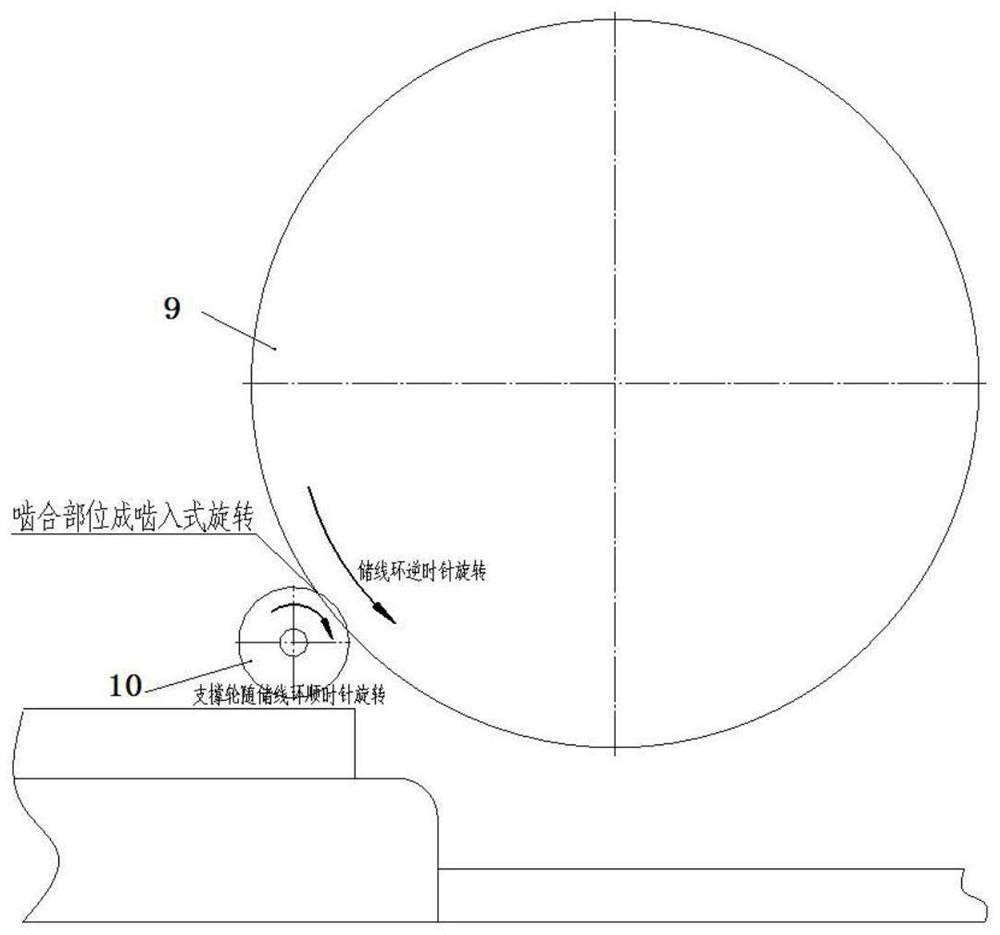

[0022] Such as Figure 1-5 As shown, a semi-automatic ring winding machine protection device includes a support 1, a shield 2, a magnet 3, and a baffle 4; the shield 2 is made of polytetrafluoroethylene, and its front side is open. 6 (the number can be adjusted according to the actual situation) end face holes 8 can be distributed on the outer periphery of the front side, and two installation elongated holes are provided on the rear side. To avoid interference with the operation of the wire storage ring, there is a communicating gap processed on the rear side of the shield 2 and the wall, such as figure 2 shown. The support 1 is L-shaped, and the two long holes 5 on the bottom surface are locked in the wire holes of the equipment base by screws. The vertical edge is provided with two silk holes 6, is used for installing and fixing the shield 2. The guard 2 wraps the support wheel inside, and the upper right corner avoids the tangent position between the storage ring and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com