Apparatus for tightening threaded fasteners

A technology of threaded fasteners and fasteners, applied in the direction of screwdrivers, manufacturing tools, wrenches, etc., can solve the problem of not being able to use access to or reach fasteners

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

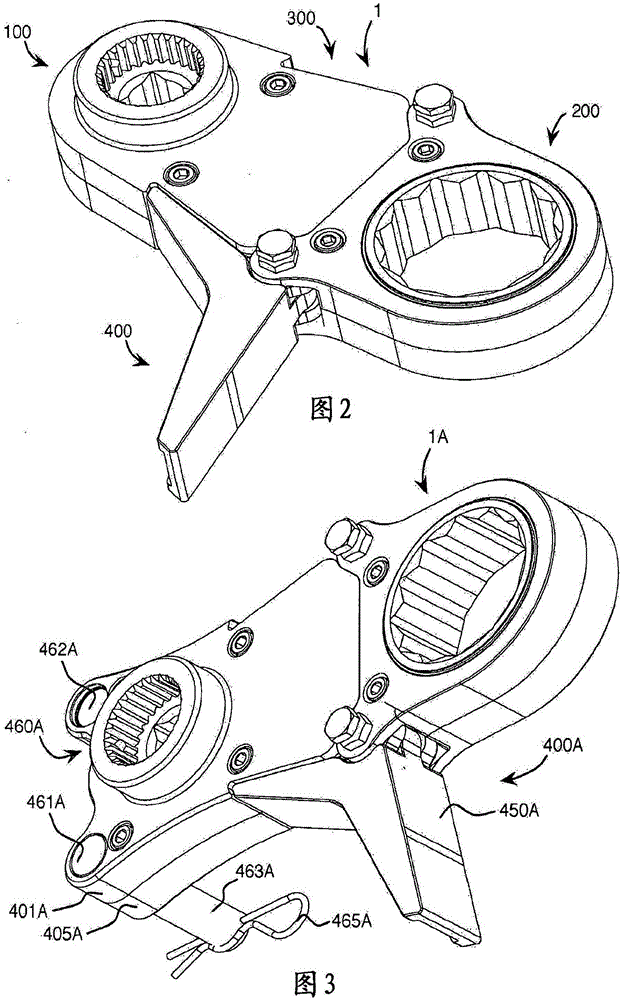

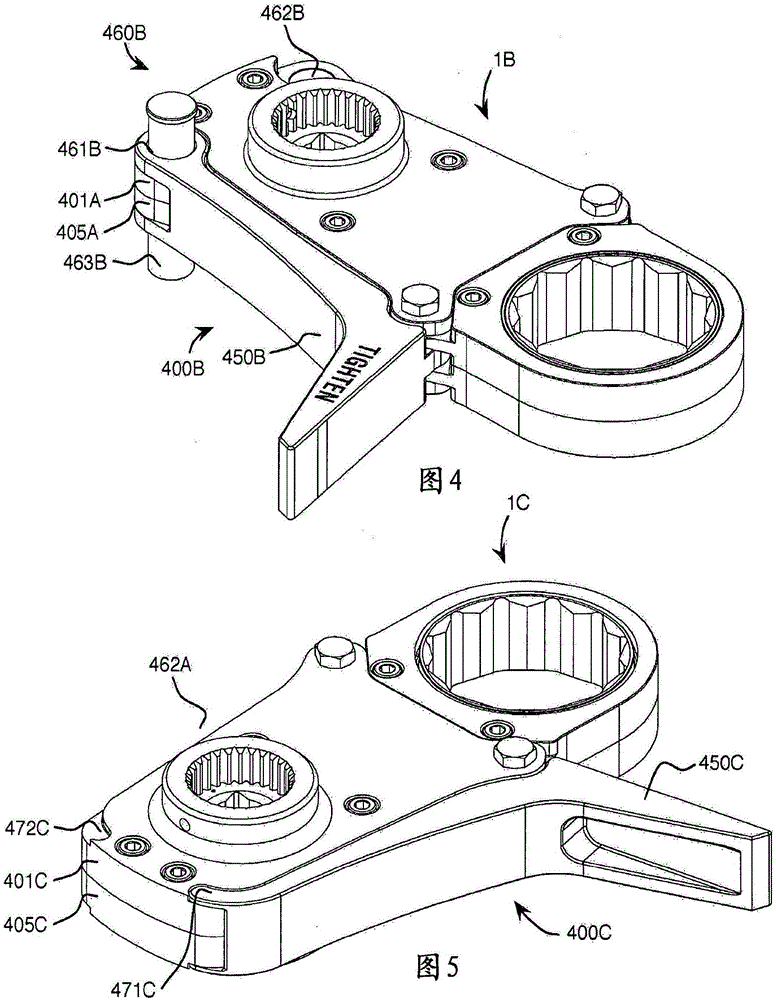

[0022] For example, refer to figure 1 A and 1B, there are shown perspective views of an embodiment of the invention as non-reaction arm apparatus 1A and 1B for tightening and loosening industrial threaded fasteners 20 with minimal galling, such The industrial threaded fastener 20 has a nut 21 , a washer 22 and a stud 23 . Devices 1A and 1B include: drive input and output assembly 100 ; rotational force multiplication assembly 200 ; vibratory force assembly 300 ; mode conversion assembly 400 ;

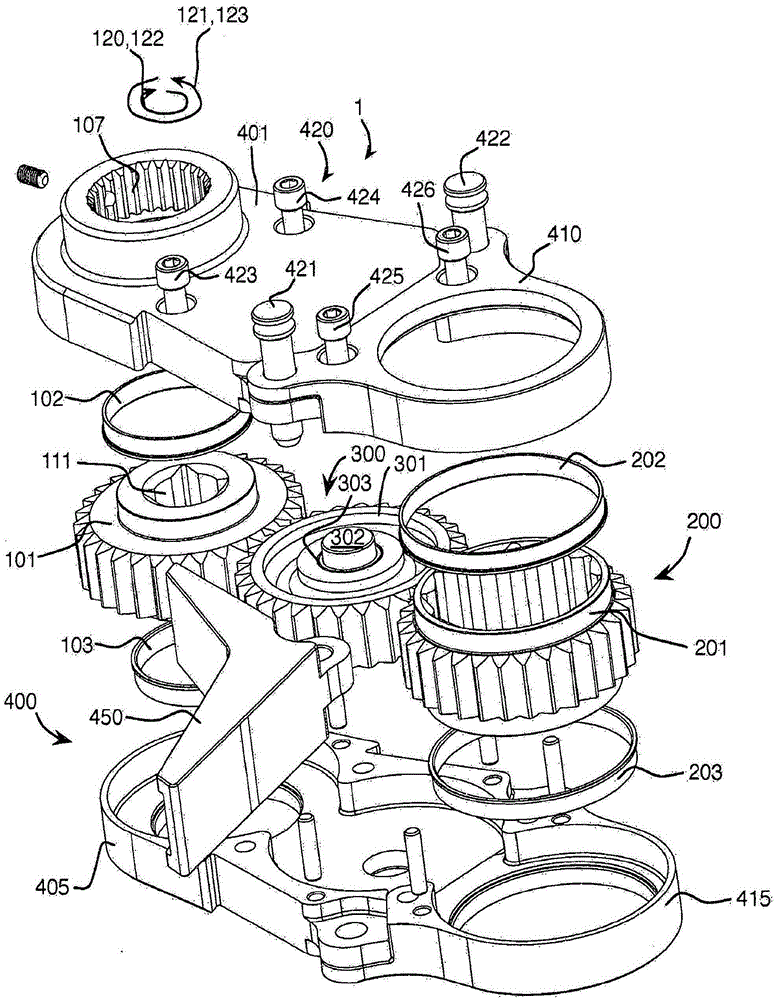

[0023] For example, refer to figure 1 , which shows an exploded perspective view of an embodiment of the present invention in the form of an apparatus 1 or offset drive linkage assembly 1 for delivering and increasing input from means for tightening or loosening threaded fasteners (not shown) ( not shown) torque. The device 1 includes: a driving force input assembly 100 ; a driving force output assembly 200 ; and a reaction force assembly 400 . The apparatus 1 also includes a drive ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com