CAC-shaft composite hinge

A hinge and ball hinge technology, used in pivot connection, metal processing, metal processing equipment, etc., can solve the problems of large volume, unsuitability, small angle range, etc., to achieve high rigidity, easy lubrication, and simple hinge structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

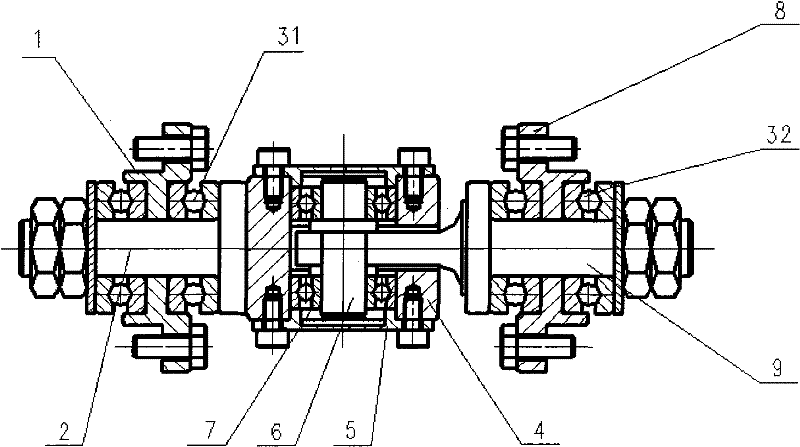

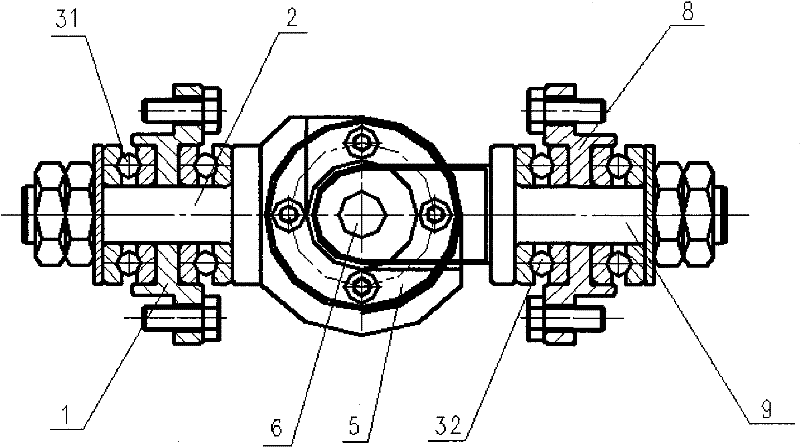

[0019] Fig. 1(a) and Fig. 1(b) are a front sectional view and a top sectional view of a CAC composite ball hinge, respectively. The left baffle plate 1, the left short shaft 2, and the left thrust ball bearing 31 form the left C-axis rotation unit; the support 4, the bearing end cover 5, the middle short shaft 6 and the deep groove ball bearing 7 form the A-axis rotation unit. Unit; the right baffle plate 8, the right short shaft 9 and the right side thrust ball bearing 32 form the right side C-axis rotation unit. The two sets of C-axis rotating units connect the hinges to the dynamic / static platform and the branch chain through the left baffle plate 1 and the right baffle plate 8 at both ends respectively, fix the dynamic / static platform and the branch chain with screws, and lock them with round nuts.

[0020] When the left thrust ball bearing 31 and the right thrust ball bearing 32 are not locked, the compound hinge is a ball hinge, which can realize three degrees of freedom...

Embodiment 2

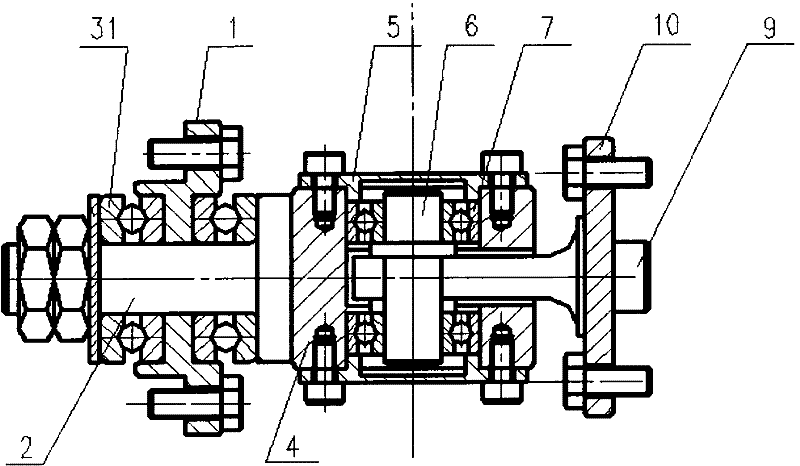

[0022] Fig. 2(a) and Fig. 2(b) are the front sectional view and top sectional view of a CA composite Hookee hinge, respectively. Compared with Embodiment 1, in this embodiment, the C-axis rotation unit on either side is replaced by a non-rotatable fixed baffle 10, so that the composite hinge loses one degree of freedom. At this time, the A-axis rotating unit composed of deep groove ball bearings 7 in the middle and another set of movable C-axis rotating units realize the functions of rotating around the A-axis and C-axis respectively, and finally realize the CA-axis Hooke The movement function of the hinge.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com