Equipment for tightening threaded fasteners

A technology for threaded fasteners and equipment, used in screwdrivers, manufacturing tools, wrenches, etc., to solve problems such as inability to use approach or reach fasteners

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

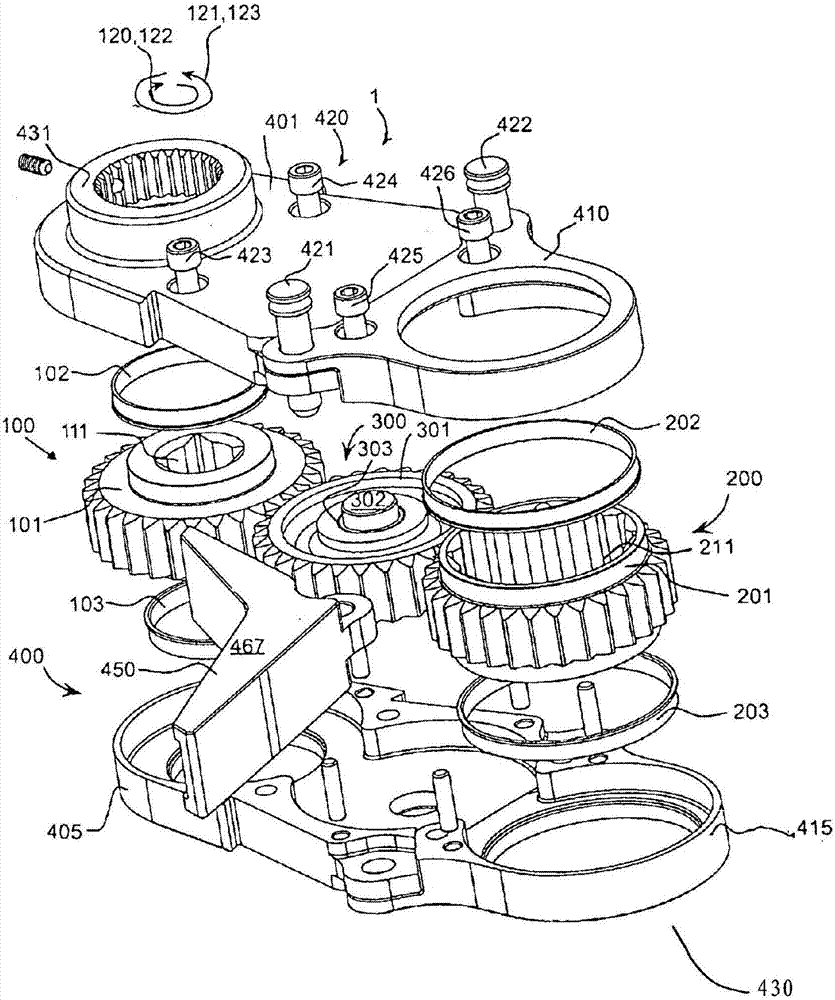

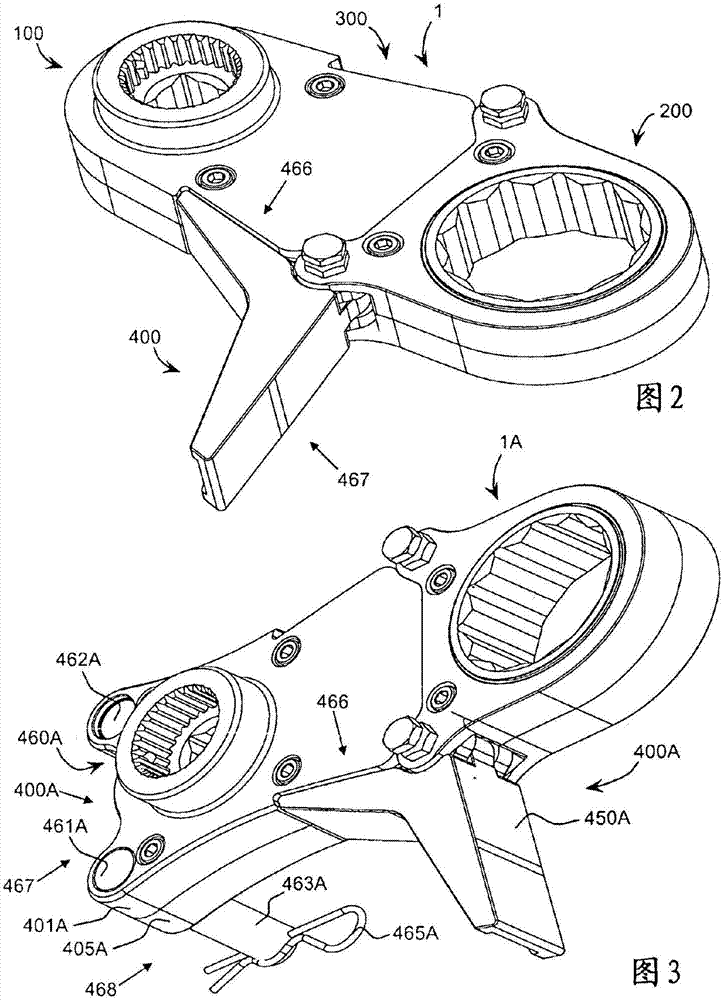

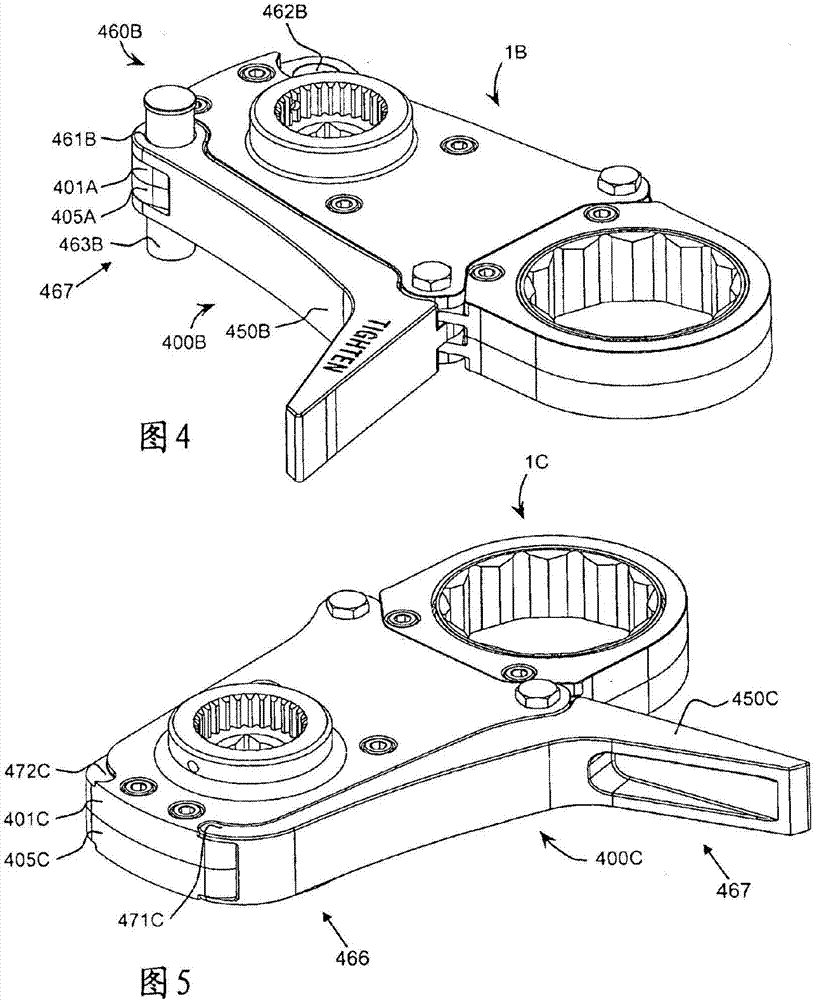

[0022] For example, refer to figure 1 , which shows an exploded perspective view of an embodiment of the present invention in the form of an apparatus 1 or offset drive linkage assembly 1 for delivering and increasing input from means for tightening or loosening threaded fasteners (not shown) ( not shown) torque. The device 1 includes: a driving force input assembly 100 ; a driving force output assembly 200 ; and a reaction force assembly 400 . The apparatus 1 also includes a drive idler assembly 300, although it will be appreciated that this is not required. For example, refer to figure 2 , which represents a perspective view of device 1.

[0023] The driving force input assembly 100 includes a driving force input gear 101 or a driving force input engaging portion 101 formed between the first and second reaction force assembly housings 401 and 405 . The first driving force input gear sleeve 102 is formed between the first reaction force assembly housing 401 and the drivi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com