Separating nut

A technology for separating nut and split nut, applied in the direction of nuts, threaded fasteners, connecting components, etc., can solve the problems of only axial load, large impact of unlocking, and many application restrictions, and achieve high reliability and unlocking impact. Low, simplified connection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The following will be described in detail in conjunction with the accompanying drawings and specific embodiments.

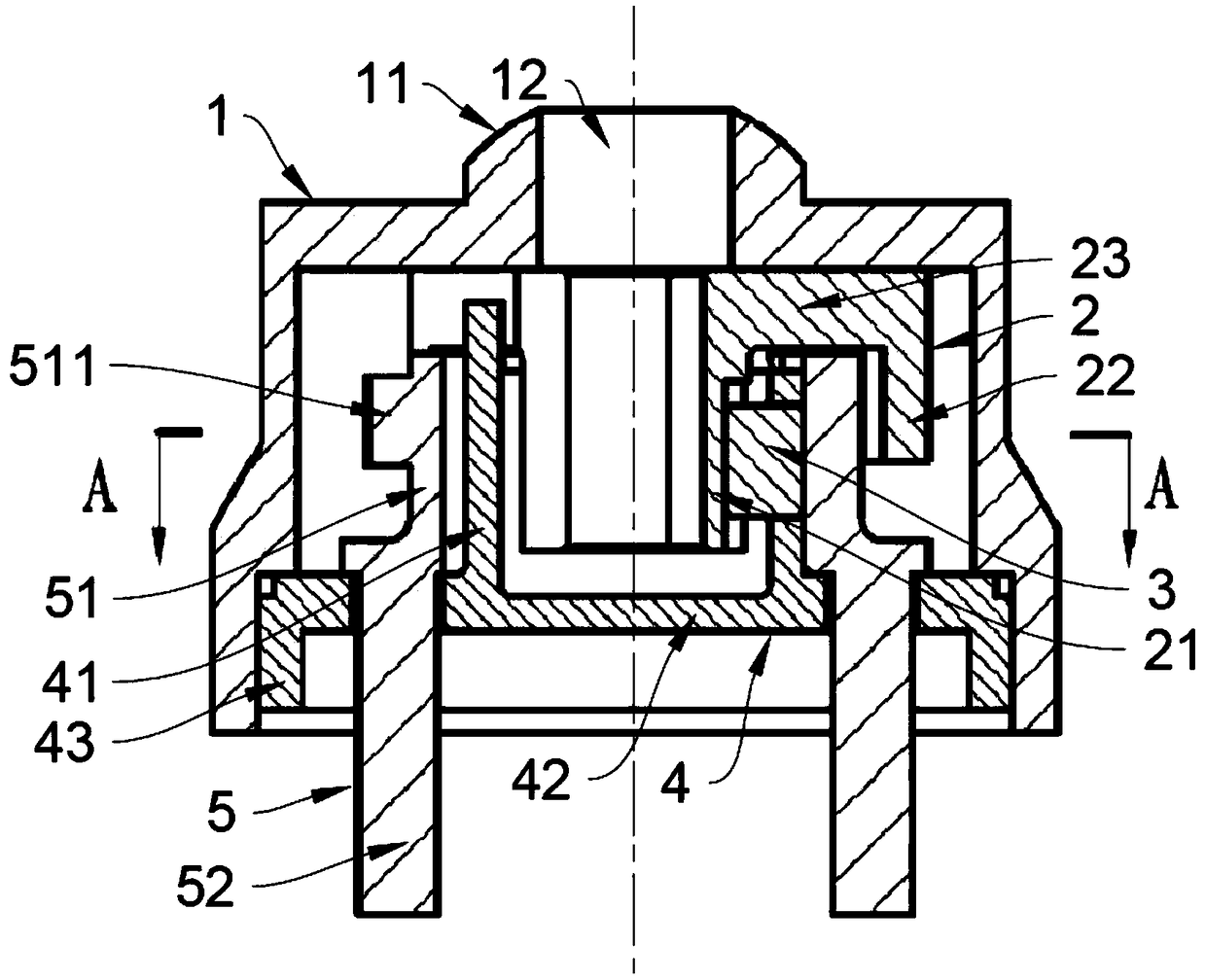

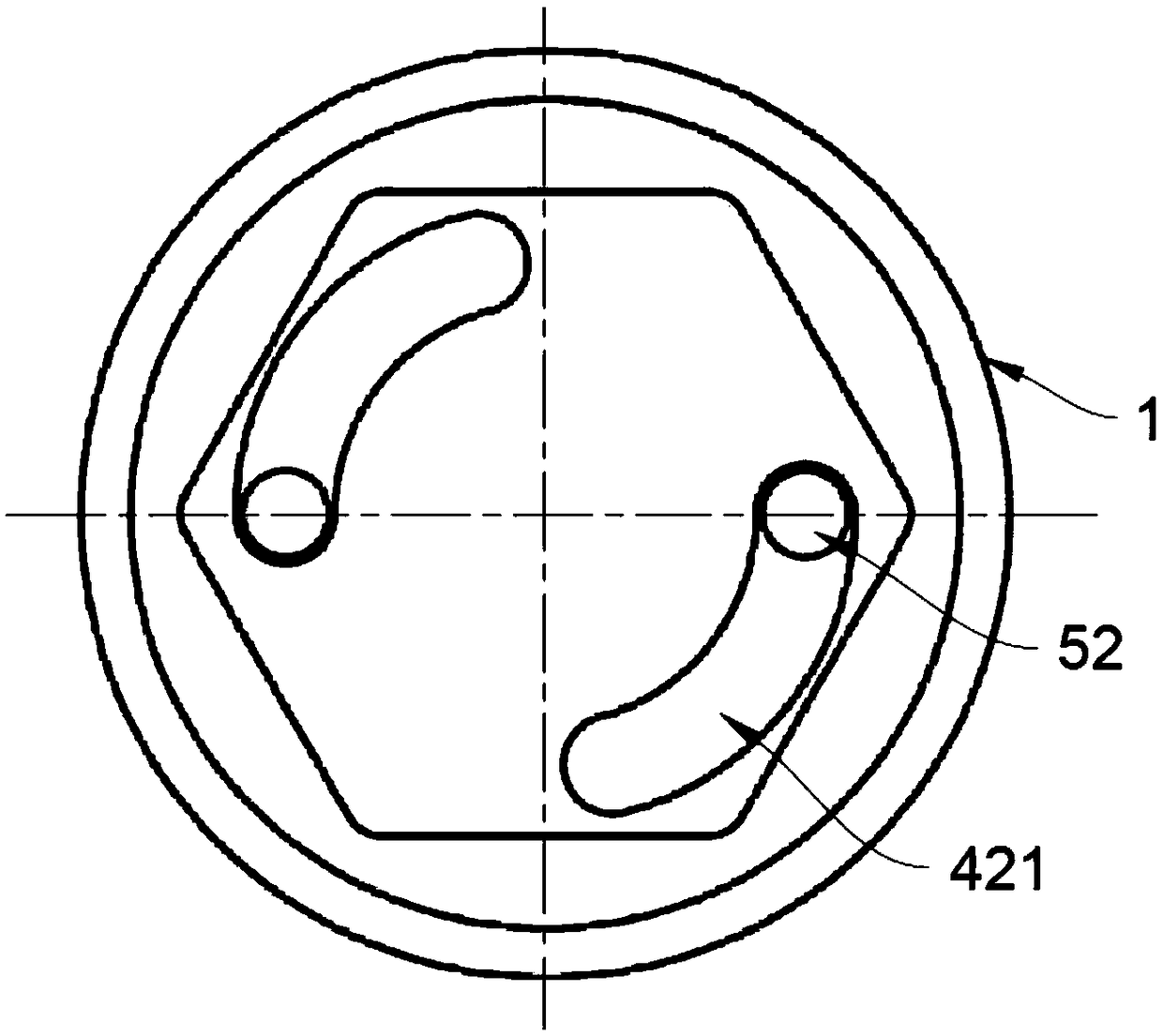

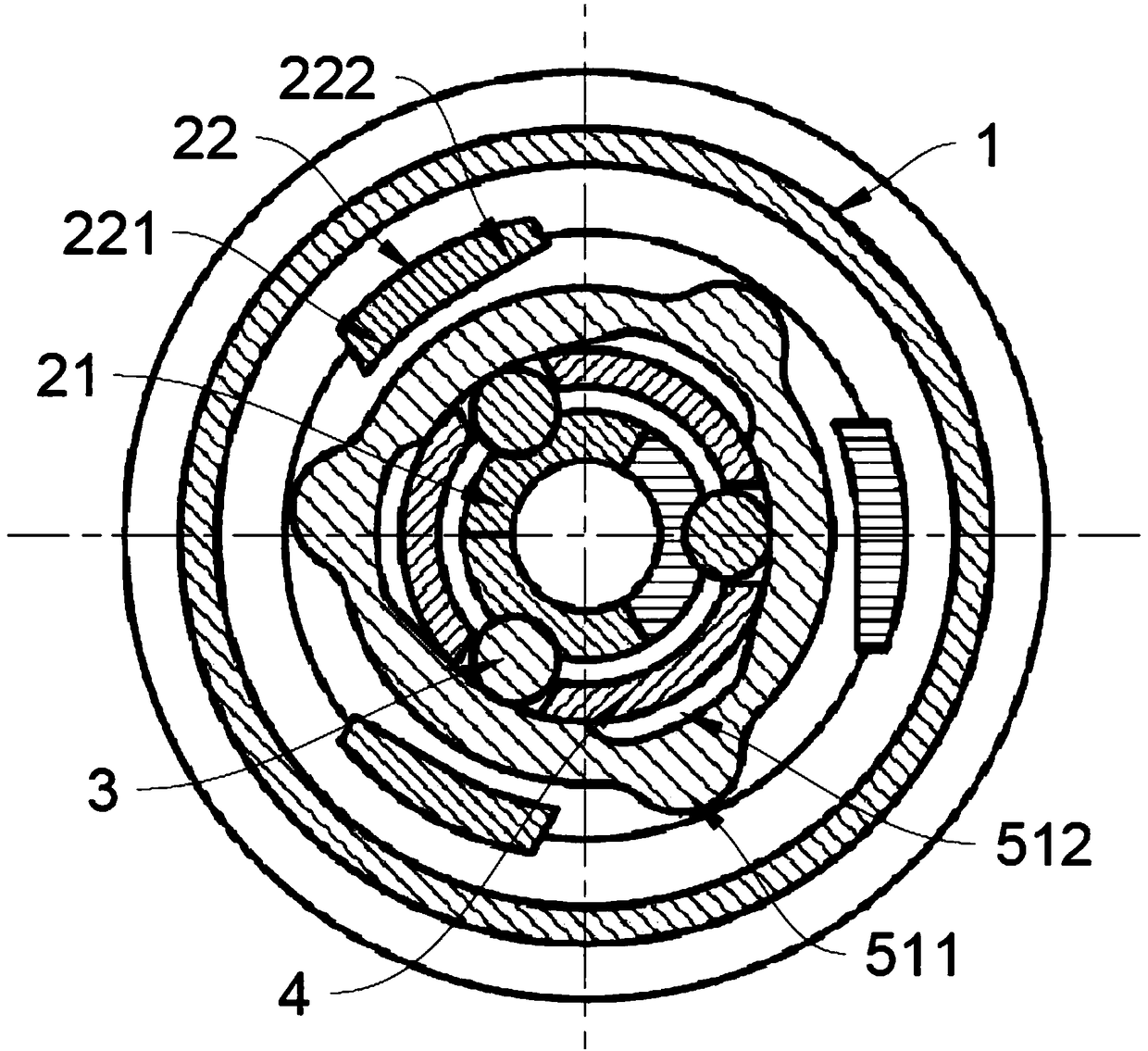

[0042] Such as Figure 1-Figure 8 As shown, a split nut is applied to a point unlocking device and connected to a split body, including a housing 1 , a split nut 2 , an annular connector 4 and a swivel 5 .

[0043] The annular connector 4 is arranged in the housing 1, and is fixed in both the axial and radial directions. The specific fixing method is as follows: interference fit between the annular connector 1 and the housing 1; but the two are not limited to this fixing method. The vertical direction of the swivel 5 is limited by the annular connector 4 or the housing 1, that is, the degree of freedom of displacement of the swivel 5 in the axial direction is constrained, but it can realize the circumferential rotation; Or push the split nuts outward. There are at least two split nuts 2, and each split nut is evenly distributed in a circle around the axi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com