Mortar fine powder and preparation method thereof

A technology of fine powder and mortar, applied in the field of fine powder of mortar and its preparation, can solve the problems of low strength and poor crack resistance of building mortar, and achieve the effects of reducing the influence of natural environment, good workability and improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

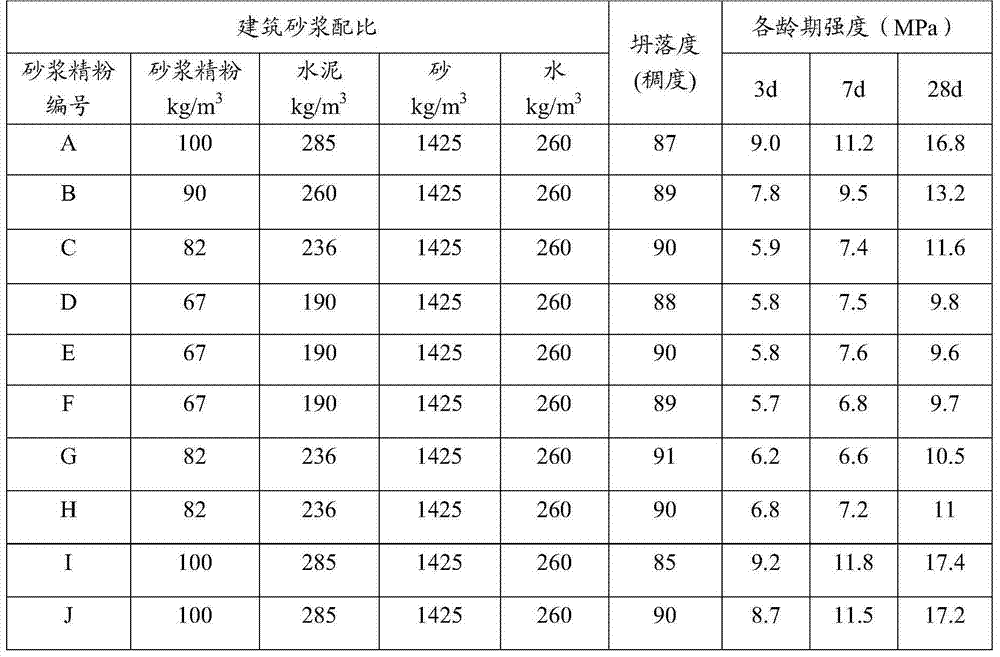

Examples

Embodiment 1

[0028] The mortar fine powder A described in this embodiment includes the following components: 9.7 kg of limestone powder with a particle diameter of 120 mesh, 0.1 kg of water-repellent silane-based powder, 0.1 kg of hydroxypropyl methylcellulose with a particle diameter of 80 mesh, and 0.05 kg of anionic polyacrylamide with a diameter of 200 mesh and a weight average molecular weight of 4 million.

[0029] The preparation method of mortar fine powder described in the present embodiment, comprises the steps:

[0030] (1) Add a specific amount of water repellent to a specific amount of limestone powder and mix evenly;

[0031] (2) Mix a specific amount of polyacrylamide and cellulose evenly;

[0032] (3) Add the homogeneously mixed substance in the step (2) to the homogeneously mixed mixture in the step (1), and stir evenly to prepare a fine mortar powder.

Embodiment 2

[0034] The mortar fine powder B described in this embodiment includes the following components: 9.8 kg of limestone powder with a particle diameter of 170 mesh, 0.08 kg of water-repellent silane-based powder, 0.04 kg of hydroxypropyl methylcellulose with a particle diameter of 120 mesh, and 0.04 kg of anionic polyacrylamide with a diameter of 170 mesh and a weight average molecular weight of 8 million.

[0035] The preparation method of mortar fine powder described in the present embodiment, comprises the steps:

[0036] (1) Add a specific amount of water repellent to a specific amount of limestone powder and mix evenly;

[0037] (2) Mix a specific amount of polyacrylamide and cellulose evenly;

[0038] (3) Add the homogeneously mixed substance in the step (2) to the homogeneously mixed mixture in the step (1), and stir evenly to prepare a fine mortar powder.

Embodiment 3

[0040] The mortar fine powder C described in this embodiment comprises the following components: 9.9 kg of limestone powder with a particle diameter of 200 mesh, 0.05 kg of calcium stearate, 0.01 kg of hydroxyethyl cellulose with a particle diameter of 170 mesh, and a particle diameter of 120 mesh , 0.01 kg of anionic polyacrylamide with a weight average molecular weight of 12 million.

[0041] The preparation method of mortar fine powder described in the present embodiment, comprises the steps:

[0042] (1) Add a specific amount of water repellent to a specific amount of limestone powder and mix evenly;

[0043] (2) Mix a specific amount of polyacrylamide and cellulose evenly;

[0044] (3) Add the homogeneously mixed substance in the step (2) to the homogeneously mixed mixture in the step (1), and stir evenly to prepare a fine mortar powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com