Method for repairing and welding copper mold bottom plate made of nodular cast iron

A technology of nodular cast iron and copper molds, applied in welding equipment, welding accessories, arc welding equipment, etc., can solve the problems of affecting the quality of copper anode plate products, increasing the cost of production unit materials, and the size cannot meet the standard requirements, etc., to achieve Avoid unnecessary waste, improve welding quality, and lower overall cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] A kind of material of the present invention is the method for repairing welding of the copper mold bottom plate of ductile iron, comprises the following steps of carrying out successively:

[0020] (1) Clean and polish the crack position of the bottom plate of the copper mold: use a ball hammer, a flat shovel, refined sandpaper, and an angle grinder to remove the inclusions at the crack of the bottom plate of the copper mold to be repaired, as well as the oil and oxide around the crack , copper penetration layer and other impurities are cleaned, and polished to reveal a metallic luster.

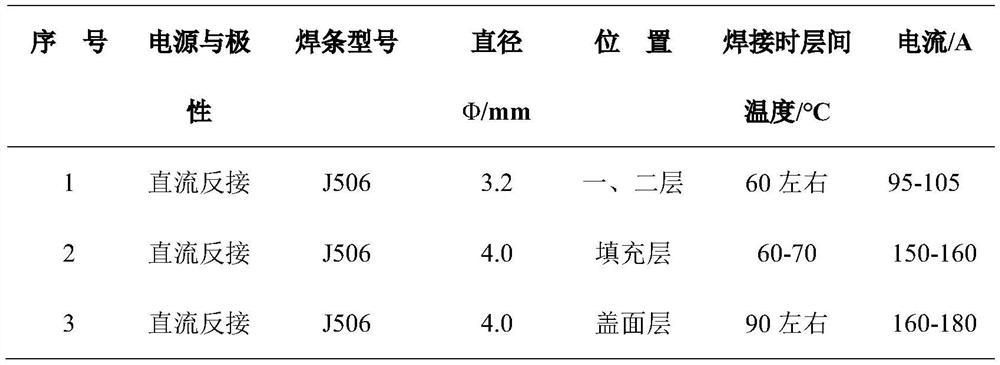

[0021] (2) Create grooves at the cracks of the copper mold bottom plate to be repaired: use a plasma cutting machine, carbon arc gouging machine, and angle grinder to cut out the bevel U on the cleaned and polished copper mold bottom plate to be repaired Shaped grooves are convenient for preventing heat-affected cracks and weld cracks and reducing pores during multi-layer multi-pass we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com