Solid welding wire for high-toughness structural steel

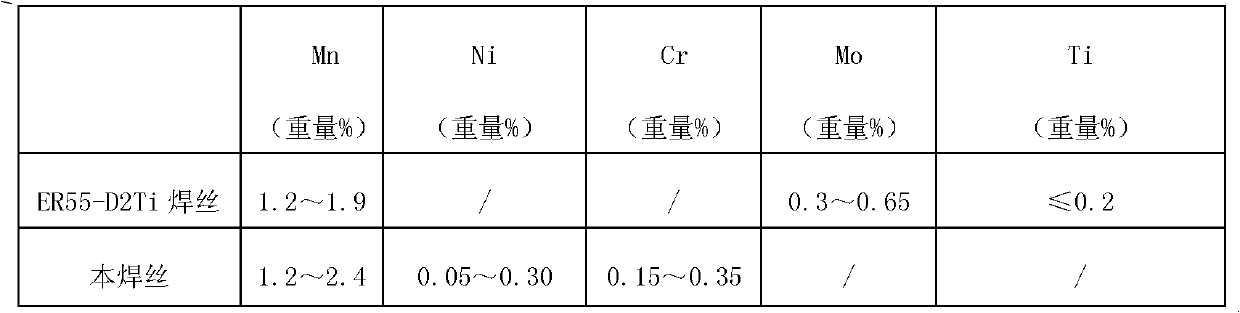

A technology of solid welding wire and structural steel, applied in welding medium, welding equipment, welding equipment, etc., can solve the problems that cannot meet the needs of gas shielded welding of low-alloy high-strength steel plates, is not suitable for large-scale promotion, and has a single variety. Rolling and wire drawing processes are easy to implement, reducing production and use costs, and the effect of stable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A 90-ton furnace is used to smelt welding wire steel with low S and P billets. The steel for welding wire is refined and rolled into steel wire rod for welding. After wire drawing, copper plating and winding processes, a welding wire of Ф1.2mm is produced. . The chemical composition of the welding wire is calculated by weight percentage: C 0.076, Mn 1.95, Si 0.65, Cr 0.22, Ni 0.15, S 0.009, P 0.010, and the balance is iron and unavoidable impurities. Copper is plated on the surface after being drawn to make welding wire, and the copper content of the welding wire is 0.10%.

[0032] Using the above Ф1.2mm welding wire, use CO 2 Gas protection, the mechanical properties test of the deposited metal is carried out on the Q345 steel plate. The welding specifications are: welding current 260-290A, welding voltage 27-31V, welding speed 33±1.5cm / min, gas flow 20L / s, welding line energy 17kJ / cm. The tensile strength of the deposited metal is 685MPa, the yield strength is 585...

Embodiment 2

[0036] A 90-ton furnace is used to smelt welding wire steel with low S and P billets. The steel for welding wire is refined and rolled into steel wire rod for welding. After wire drawing, copper plating and winding processes, a welding wire of Ф1.2mm is produced. . The chemical composition of the wire is by weight percentage: C 0.076, Mn 1.86, Si 0.60, Cr 0.18, Ni0.08, Ti 0.08, S 0.0043, P 0.013, and the balance is iron and unavoidable impurities. Copper is plated on the surface after being drawn to make welding wire, and the copper content of the welding wire is 0.10%.

[0037] Using the above Ф1.2mm welding wire, use CO 2Gas shielding, the mechanical properties test of the deposited metal is carried out on the Q345 steel plate. The welding specification is: welding current 260-290A, welding voltage 27-31V, welding speed 33±1.5cm / mi, gas flow rate 20L / s, welding line energy 17kJ / cm . The tensile strength of the deposited metal is 685MPa, the yield strength is 585MPa, the e...

Embodiment 3

[0041] A 90-ton furnace is used to smelt welding wire steel with low S and P billets. The steel for welding wire is refined and rolled into steel wire rod for welding. After wire drawing, copper plating and winding processes, a welding wire of Ф1.2mm is produced. . The chemical composition of the welding wire is calculated by weight percentage: C 0.083, Mn 1.72, Si 0.59, Ti0.08, S 0.010, P 0.015, Ni 0.13, Cr 0.24, and the balance is iron and unavoidable impurities. The surface of the welding wire is plated with copper after drawing, and the copper content of the welding wire is 0.12%.

[0042] Using the above Ф1.2mm welding wire, use CO 2 Gas protection, the mechanical properties test of the deposited metal is carried out on the Q345 steel plate. The welding specifications are: welding current 260-290A, welding voltage 27-31V, welding speed 33±1.5cm / min, gas flow 20L / s, welding line energy 17kJ / cm. The tensile strength of the deposited metal is 665MPa, the yield strength i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com