Inorganic anticorrosive coating layer for high-strength metal

An anti-corrosion coating and high-strength technology, applied in anti-corrosion coatings, coatings, etc., can solve problems such as high cracking strain of only 2000 microstrain, easy aging of epoxy resin coating, and failure to reach high-strength steel bars, etc., to improve cracking strain and impact resistance, increased brittleness, and improved brittleness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

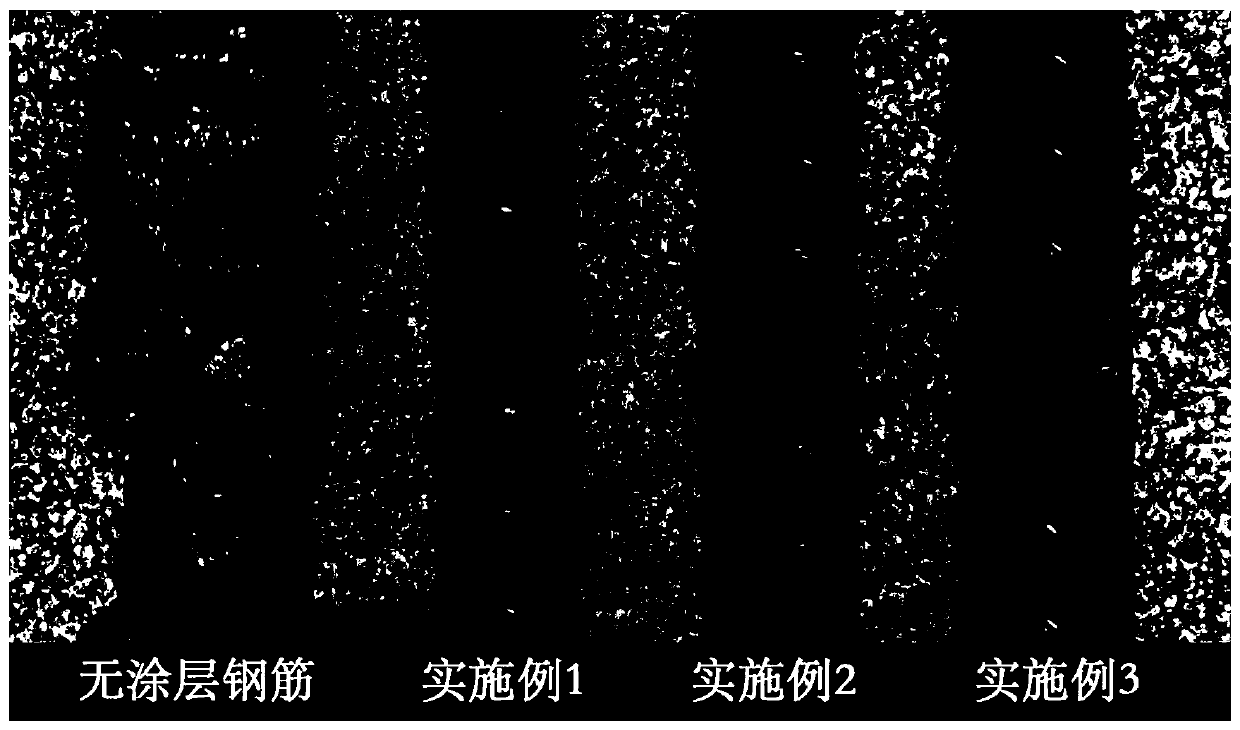

Embodiment 1

[0027]Preparation of paint: Take 150 grams of silicon dioxide, 100 grams of phosphorus pentoxide, 75 grams of aluminum oxide, 32.5 grams of sodium carbonate, 6 grams of potassium carbonate, 50 grams of calcium fluoride, 25 grams of boron oxide, 3 grams of nickel monoxide, 8.5 gram of cobalt monoxide, mixed evenly, and ground to make the powder through a 200-mesh sieve; get 25 grams of basalt fiber (diameter 1-2 micron, length 20-50 micron) and 25 gram of aluminum silicate fiber (diameter 1-2 micron , length 20-50 microns) into the sieved powder, mix evenly, set aside.

[0028] Substrate treatment: use sandblasting to remove rust and dirt on the surface of the steel bar, and dry it for later use; the steel bar is a HRB600 threaded steel bar with a strain of less than or equal to 2800 microstrains during use.

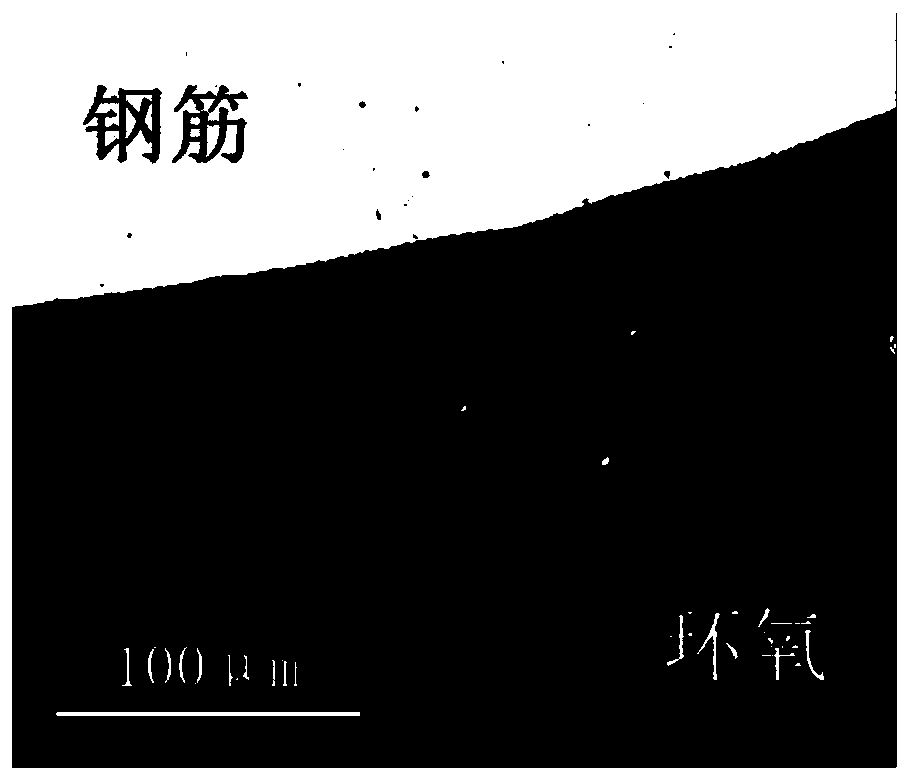

[0029] Coating: Ground the treated steel bar, and use an electrostatic spray gun to evenly coat the powder on the surface of the steel bar. The electrostatic voltage is 6...

Embodiment 2

[0033] Preparation of paint: Take 50 grams of silicon dioxide, 75 grams of silica, 50 grams of quartz, 75 grams of phosphorus pentoxide, 100 grams of alumina, 20 grams of sodium carbonate, 32 grams of potassium carbonate, 37 grams of calcium fluoride, 6 grams of trioxide Dinickel, 2 grams of cobalt monoxide, 3 grams of cobalt trioxide, mixed evenly and then ground to make the powder pass through a 200-mesh sieve; get 50 grams of aluminum silicate fiber (diameter 1-2 micron, length 20-50 micron) Add to the sifted powder, mix well and set aside.

[0034] Substrate treatment: use sandblasting to remove rust and dirt on the surface of the steel bar, and dry it for later use; the steel bar is a HRB600 threaded steel bar with a strain of less than or equal to 2800 microstrains during use.

[0035] Coating: Mix the powder and absolute ethanol at a mass ratio of 1.8:1, make it milky and shake well, dip the treated steel bar in the slurry for 5 seconds and take it out. The thickness is...

Embodiment 3

[0039] Preparation of paint: Take 125 grams of quartz, 100 grams of phosphorus pentoxide, 100 grams of aluminum oxide, 15.5 grams of sodium carbonate, 35 grams of calcium fluoride, 40 grams of boron oxide, 5.5 grams of nickel monoxide, 4 grams of cobalt trioxide, mix Grind after uniformity to make the powder pass through a 200-mesh sieve; take 50 grams of basalt fiber (2-5 microns in diameter, 50-80 microns in length), and 25 grams of calcium carbonate fiber (0.2-1 micron in diameter, 10-20 microns in length) Add to the sifted powder, mix well and set aside.

[0040] Substrate treatment: use sandblasting to remove rust and dirt on the surface of the steel bar, and dry it for later use; the steel bar is a HRB600 threaded steel bar with a strain of less than or equal to 2800 microstrains during use.

[0041] Coating: Ground the treated steel bar, and use an electrostatic spray gun to evenly coat the powder on the surface of the steel bar. The electrostatic voltage is 65 kV, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com