A series of low-silver lead-free solder for electronic package soldering and preparation method thereof

A lead-free solder, electronic packaging technology, used in welding equipment, welding/cutting media/materials, welding media, etc., can solve the problems of poor wettability and mechanical properties, high silver content, and achieve good wettability, The effect of low rate of Cu dissolution and high tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

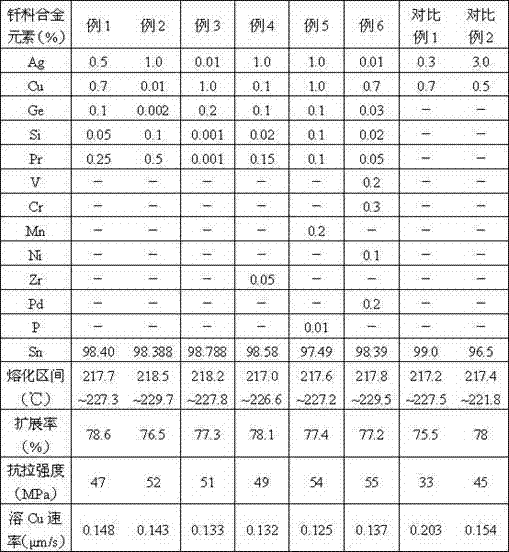

[0035] The composition and mass percentage of a series of low-silver lead-free solder for electronic packaging soft soldering are: Ag: 0.5%, Cu: 0.7%, Ge: 0.1%, Si: 0.05%, Pr: 0.25%, Sn : 98.4%.

[0036] The Sn-Pr master alloy containing 5% Pr and the Sn-Si containing 1% Si were prepared in a vacuum melting furnace.

[0037] Inter-alloy; heat the mixed salt of 195g of KCl and 150g of LiCl at 500℃ to melt, then cover it on the surface of 887gSn, keep it for 30 minutes; heat the molten tin to 600℃, add 50gSn-Si intermediate alloy, uniform Stir and hold for 30 minutes to obtain a molten Sn-Si alloy; then cool the molten Sn-Si alloy to 500°C, add 50g of Sn-Pr master alloy, and stir uniformly for 40 minutes to obtain a molten Sn-Si-Pr alloy; Cool down the molten Sn-Si-Pr alloy to 400°C, add 5gAg, 7gCu and 1gGe, stir evenly, keep for 120 minutes, get the molten Sn-Ag-Cu-Si-Pr-Ge alloy, stand it out of the furnace, and cast it on the stainless steel In the mold, the mixed salt on the su...

Embodiment 2

[0039] The composition and mass percentage of a series of low-silver lead-free solder for electronic packaging soft soldering are: Ag: 1.0%, Cu: 0.01%, Ge: 0.002%, Si: 0.1%, Pr: 0.5%, Sn : 98.388%.

[0040] The Sn-Pr master alloy containing 5% Pr and the Sn-Si containing 1% Si were prepared in a vacuum melting furnace.

[0041] Inter-alloy; heat the mixed salt of 195g of KCl and 150g of LiCl at 550℃ to melt it, then cover it on the surface of 789.88gSn, keep it for 40 minutes; heat the molten tin to 700℃, add 100g of Sn-Si intermediate alloy , Stir uniformly and keep for 40 minutes to obtain a molten Sn-Si alloy; then cool the molten Sn-Si alloy to 600°C, add 100g of Sn-Pr master alloy, and stir uniformly for 30 minutes to obtain a molten Sn-Si-Pr alloy ; Then the molten Sn-Si-Pr alloy is cooled to 500 ℃, 10gAg, 0.1gCu and 0.02gGe are added, stir evenly, and hold for 60 minutes to obtain the molten Sn-Ag-Cu-Si-Pr-Ge alloy , Pouring in a stainless steel mold, and removing the mixe...

Embodiment 3

[0043] The composition and mass percentage of a series of low-silver lead-free solder for electronic packaging soft soldering are: Ag: 0.01%, Cu: 1.0%, Ge: 0.2%, Si: 0.001%, Pr: 0.001%, Sn : 98.788%.

[0044] The Sn-Pr master alloy containing 5% Pr and the Sn-Si containing 1% Si were prepared in a vacuum melting furnace.

[0045] Inter-alloy; heat and melt the mixed salt of 195g KCl and 150g LiCl at 520℃, then cover it on the surface of 986.7gSn, keep it for 35 minutes; heat the molten tin to 650℃, add 1gSn-Si intermediate alloy , Stir uniformly and keep for 35 minutes to obtain a molten Sn-Si alloy; then cool the molten Sn-Si alloy to 550°C, add 0.2g Sn-Pr master alloy, and stir evenly for 35 minutes to obtain a molten Sn-Si-Pr Alloy; then cool the molten Sn-Si-Pr alloy to 450°C, add 0.1gAg, 10gCu and 2gGe, stir evenly, keep for 100 minutes to obtain the molten Sn-Ag-Cu-Si-Pr-Ge alloy , Pouring in a stainless steel mold, and removing the mixed salt on the surface after solidific...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com