A rare earth weather-resistant bridge steel plate with a yield strength of 370mpa and its preparation method

A technology with a yield strength of 370mpa, applied in the field of rare earth weather-resistant bridge steel plates with a yield strength of 370MPa and its preparation, can solve the problems of easy cracks and other problems, and achieve the effects of short production cycle, low production cost and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The present invention also provides a method for preparing the above-mentioned weather-resistant bridge steel plate, which includes the following steps:

[0026] Step 1), smelting according to the above chemical composition, and casting into a rectangular steel ingot;

[0027] Step 2), steel ingot is heated and rolled, wherein:

[0028] During the heating process, the heating temperature is 1200℃~1220℃, and the total time in the furnace is ≥240min;

[0029] Rolling is divided into first stage and second stage rolling:

[0030] The first stage is rolled in the austenite recrystallization zone. During the rolling process, the rolling start temperature is 1130-1180°C. The reduction in the first to second passes should be greater than 10%, and the rest should be at least 1 to 2 passes. The drop rate is controlled above 25%;

[0031] The second stage is rolled in the austenite non-recrystallized area, the starting rolling temperature is ≤930°C, the thickness of the interm...

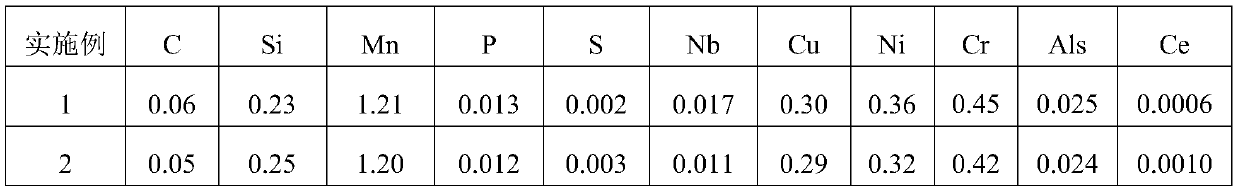

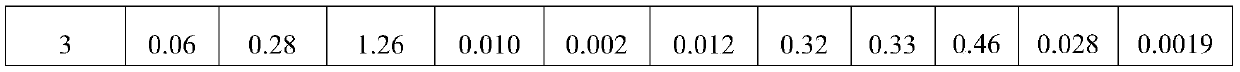

Embodiment 1

[0042]Smelt according to the chemical composition shown in Table 1, and cast into steel ingots, heat the steel ingots to 1210 ° C, and the total time in the furnace is 252 minutes, and carry out the first stage of rolling on the experimental rolling mill, that is, rolling in the austenite recrystallization zone. The rolling start temperature is 1176°C, the reduction in the first to second passes should be greater than 10%, and the reduction rate in at least 1 to 2 passes should be controlled above 25%. Temperature to 930 ° C, followed by the second stage of rolling, that is, rolling in the austenite non-recrystallized zone. The final rolling temperature is 830°C, and the thickness of the finished steel plate is 14mm. After rolling, the steel plate enters the laminar flow cooling device and is cooled to 630°C at a rate of 10°C / s, and finally the steel plate can be obtained.

Embodiment 2

[0044] The implementation is the same as in Example 1, wherein the heating temperature is 1220°C, the total time in the furnace is 256 minutes, the rolling start temperature of the first stage rolling is 1175°C, the thickness of the intermediate billet is 60mm, and the rolling start temperature of the second stage rolling is The temperature is 925°C, the final rolling temperature is 836°C, and the thickness of the finished steel plate is 20mm. After rolling, the steel plate enters the laminar flow cooling device and is cooled to 620°C at a rate of 12°C / s, and finally the steel plate can be obtained. The metallographic structure of the steel plate is shown in figure 1 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com