Titanium-reinforced low-cost Q390 grade hot rolled plate and production method thereof

A production method and technology for hot-rolled coils, applied in the metallurgical field, can solve the problems of poor coating, high alloy consumption and high alloy content, and achieve the effects of reduced alloy cost, good welding performance and low alloy content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

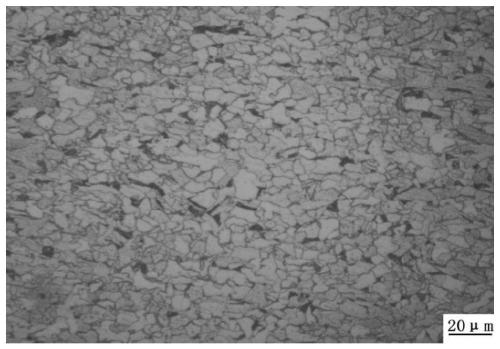

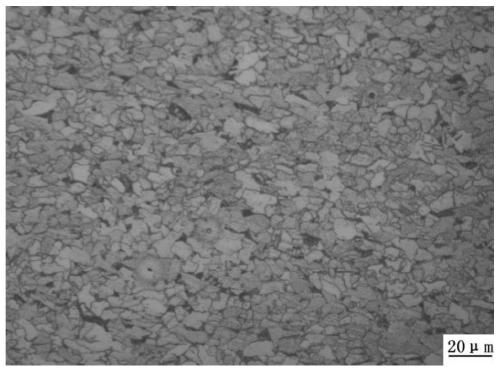

Image

Examples

Embodiment 1

[0028] In this example, the thickness of the finished titanium-enhanced low-cost Q390 grade hot-rolled coil is 3 mm, and its chemical composition and mass percentage are: C: 0.15%, Si: 0.08%, Mn: 0.45%, P: 0.008%, S : 0.005%, Als: 0.026%, Ti: 0.050%, N: 0.0035%, the balance is Fe and unavoidable impurities; Ceq: 0.23.

[0029] The production method of titanium-enhanced low-cost Q390 grade hot-rolled coil plate in this embodiment includes smelting, refining, continuous casting, slab heating, controlled rolling, controlled cooling, and coiling processes. The specific process steps are as follows:

[0030] (1) Smelting process: the blowing process ensures early slag formation in the early stage of smelting, and the initial slag formation time is 4 minutes. The use of low-temperature dephosphorization requires a stable rise in furnace temperature; post-stirring is required before tapping, and the post-stirring time is 101s to ensure molten steel in the furnace Uniform, accurate sa...

Embodiment 2

[0039]In this example, the thickness of the finished titanium-enhanced low-cost Q390 grade hot-rolled coil is 5 mm, and its chemical composition and mass percentage are: C: 0.16%, Si: 0.05%, Mn: 0.47%, P: 0.009%, S : 0.003%, Als: 0.036%, Ti: 0.048%, N: 0.0038%, the balance is Fe and unavoidable impurities; Ceq: 0.24.

[0040] The production method of titanium-enhanced low-cost Q390 grade hot-rolled coil plate in this embodiment includes smelting, refining, continuous casting, slab heating, controlled rolling, controlled cooling, and coiling processes. The specific process steps are as follows:

[0041] (1) Smelting process: the blowing process ensures early slag formation in the early stage of smelting, and the initial slag formation time is 4.2 minutes. Using low-temperature dephosphorization, the furnace temperature is required to rise steadily; post-stirring is required before tapping, and the post-stirring time is 102s to ensure that the furnace The molten steel is uniform...

Embodiment 3

[0050] In this example, the thickness of the finished titanium-enhanced low-cost Q390 grade hot-rolled coil is 12mm, and its chemical composition and mass percentage are: C: 0.17%, Si: 0.08%, Mn: 0.50%, P: 0.008%, S : 0.003%, Als: 0.018%, Ti: 0.052%, N: 0.0041%, the balance is Fe and unavoidable impurities; Ceq: 0.25.

[0051] The production method of titanium-enhanced low-cost Q390 grade hot-rolled coil plate in this embodiment includes smelting, refining, continuous casting, slab heating, controlled rolling, controlled cooling, and coiling processes. The specific process steps are as follows:

[0052] (1) Smelting process: the blowing process ensures early slag formation in the early stage of smelting, and the initial slag formation time is 4.3 minutes. Using low-temperature dephosphorization, the furnace temperature is required to rise steadily; post-stirring is required before tapping, and the post-stirring time is 105s to ensure that the furnace The molten steel is unifor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com