A kind of aluminum-lithium alloy material with added tin, zinc and manganese and production method thereof

A technology of an aluminum-lithium alloy and a production method, which is applied to the aluminum-lithium alloy material with tin-zinc-manganese addition and its production field, can solve the problems of improving the aluminum-lithium alloy and the like, and achieve the effects of preventing hydrogen absorption, low cost, and material quality reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

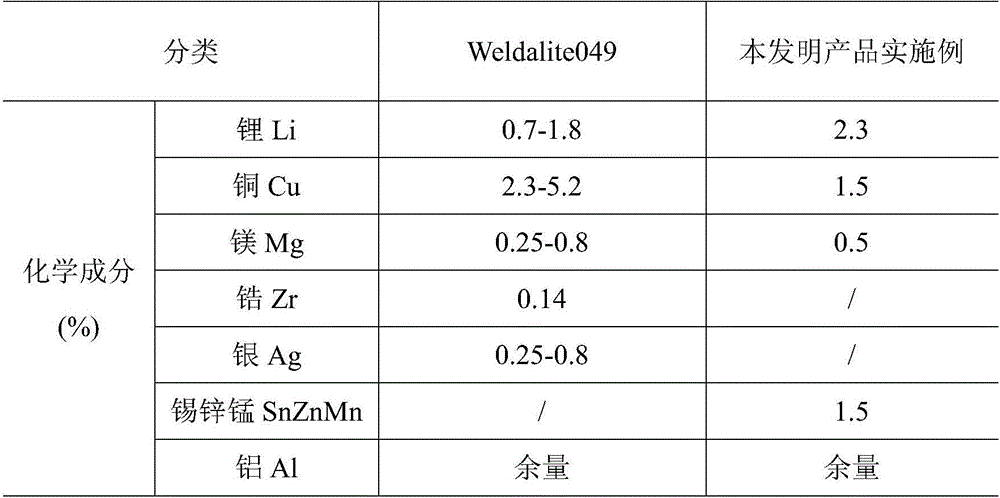

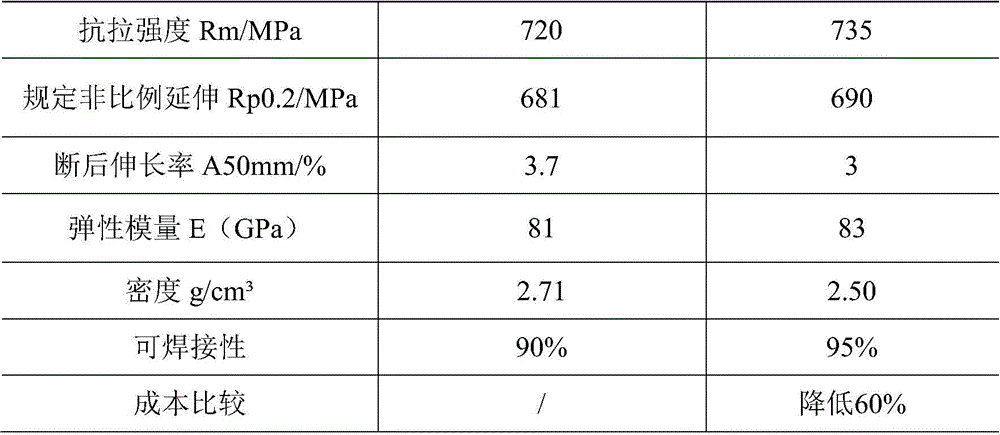

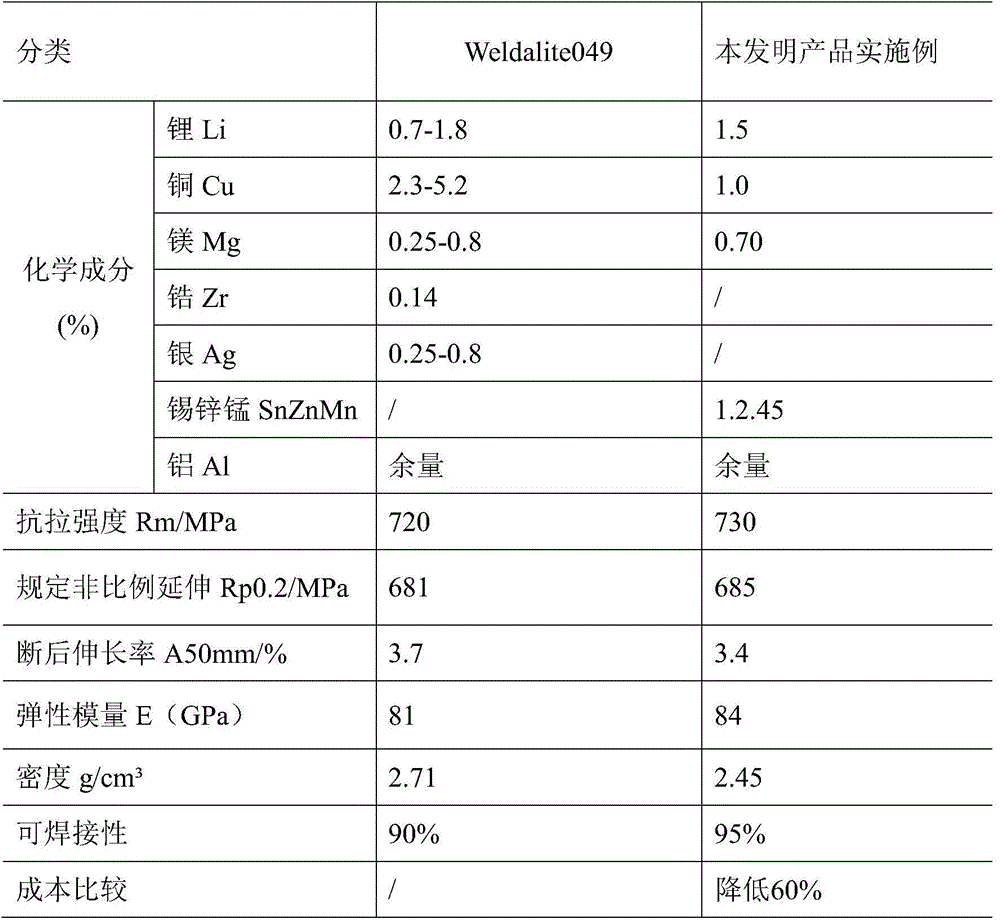

Embodiment 1

[0028] Embodiment 1 Preparation of aluminum-lithium alloy material of the present invention

[0029] Batching smelting: The metals are tin-zinc-manganese alloy particles according to the weight ratio: 1.5wt%, lithium: 2.5wt%, copper: 1.5wt%, magnesium: 0.05wt%, and the balance: aluminum is smelted in a closed and inert gas Mix well in the furnace, increase the temperature of the melting furnace, and melt at 300° C. for 3 hours.

[0030] Detection: Spectroscopic analysis is used to detect the smelted alloy liquid to ensure that its composition is within the range.

[0031] Vacuum smelting: heat the alloy liquid to 700°C and place it in a vacuum melting furnace for remelting. Under the conditions of 700°C and 500Pa vacuum, vacuum smelt for 20 minutes.

[0032] Hydrogen absorption detection: through volumetric method, gravimetric method and other chemical methods to detect the hydrogen absorption of the alloy to be less than or equal to the mass fraction of 1×10 -7 .

[0033] ...

Embodiment 2

[0041] Embodiment 2 Preparation of aluminum-lithium alloy material of the present invention

[0042] Batching smelting: The metals are smelted by weight ratio as tin-zinc-manganese alloy particles: 2.5wt%, lithium: 1.5wt%, copper: 1.0wt%, magnesium: 0.75wt%, balance: aluminum in a closed smelting with inert gas Mix well in the furnace, increase the temperature of the melting furnace, and melt at 310° C. for 2 hours.

[0043] Detection: Spectroscopic analysis is used to detect the smelted alloy liquid to ensure that its composition is within the range.

[0044] Vacuum melting: heat the alloy liquid to 700°C and put it in a vacuum melting furnace for melting again. Under the conditions of 700°C temperature and 1000Pa vacuum degree, vacuum melting is carried out for 20 minutes.

[0045] Hydrogen absorption detection: through volumetric method, gravimetric method and other chemical methods to detect the hydrogen absorption of the alloy to be less than or equal to the mass fractio...

Embodiment 3

[0053] Embodiment 3 Preparation of aluminum-lithium alloy material of the present invention

[0054]Batching smelting: The metals are smelted by weight ratio as tin-zinc-manganese alloy particles: 2.0wt%, lithium: 2.0wt%, copper: 2.0wt%, magnesium: 0.2wt%, balance: aluminum in closed smelting with inert gas Mix well in the furnace, increase the temperature of the melting furnace, and melt at 310° C. for 3 hours.

[0055] Detection: Spectroscopic analysis is used to detect the smelted alloy liquid to ensure that its composition is within the range.

[0056] Vacuum smelting: heat the alloy liquid to 700°C and place it in a vacuum melting furnace for remelting. Under the conditions of 700°C and 2000Pa vacuum, vacuum smelt for 20 minutes.

[0057] Hydrogen absorption detection: through volumetric method, gravimetric method and other chemical methods to detect the hydrogen absorption of the alloy to be less than or equal to the mass fraction of 1×10 -7 .

[0058] Casting cold bi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com