Method for exposing single-sided flexible circuit board

A flexible circuit board and exposure method technology, applied in the field of circuit board manufacturing, can solve the problems of alignment deviation, affecting product yield, dislocation of the first FPC and the first film, etc., so as to improve the production effect, increase the exposure capacity, improve The effect of utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

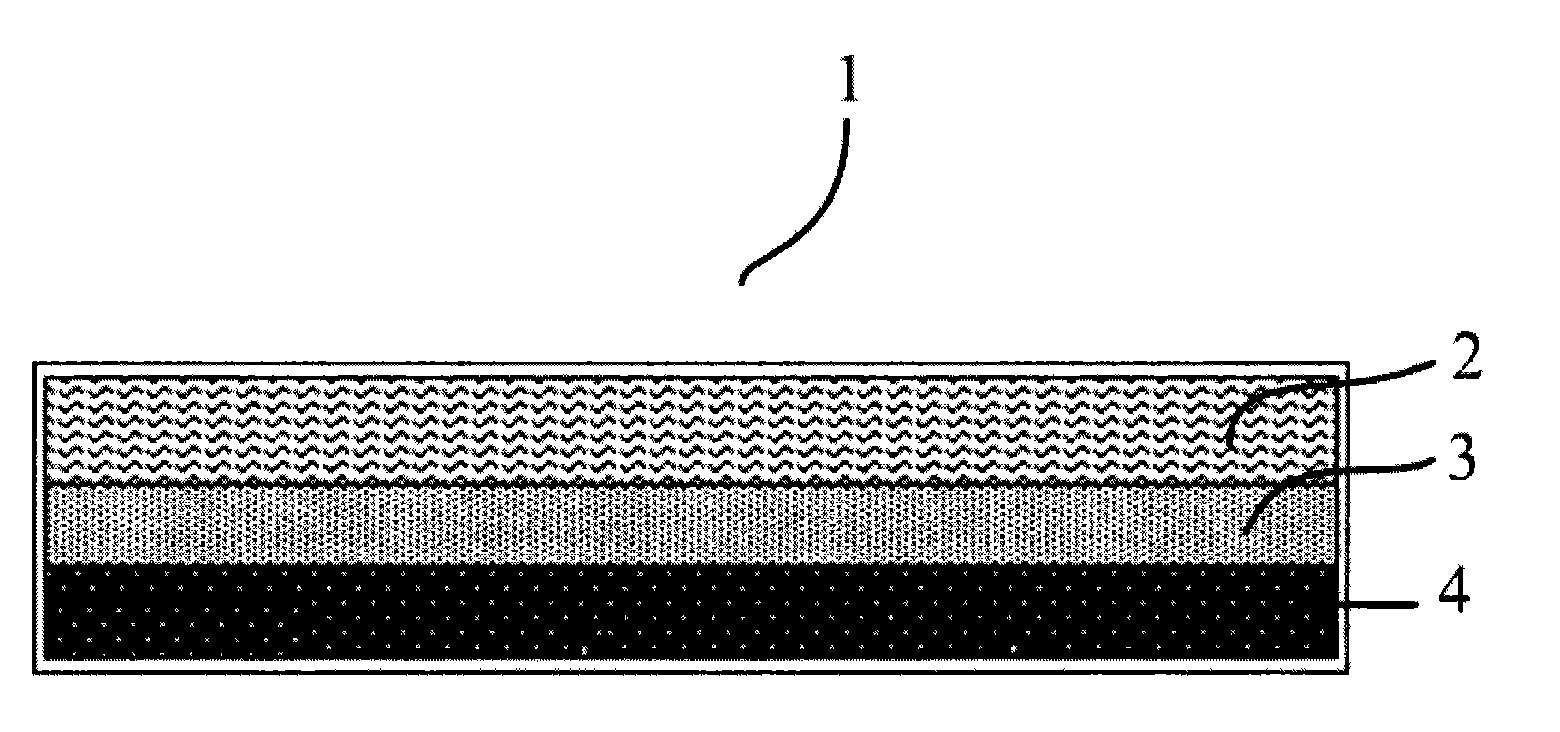

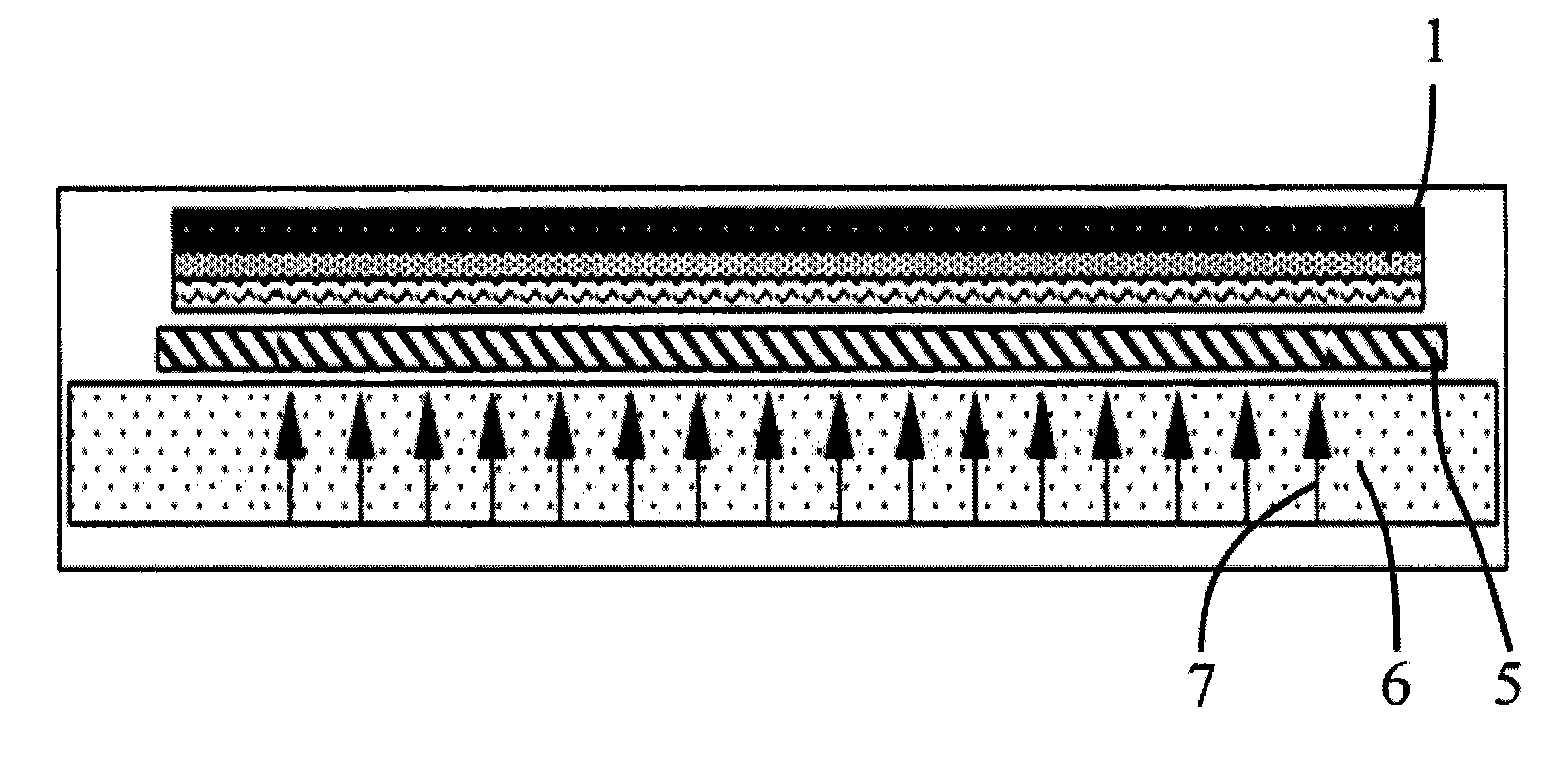

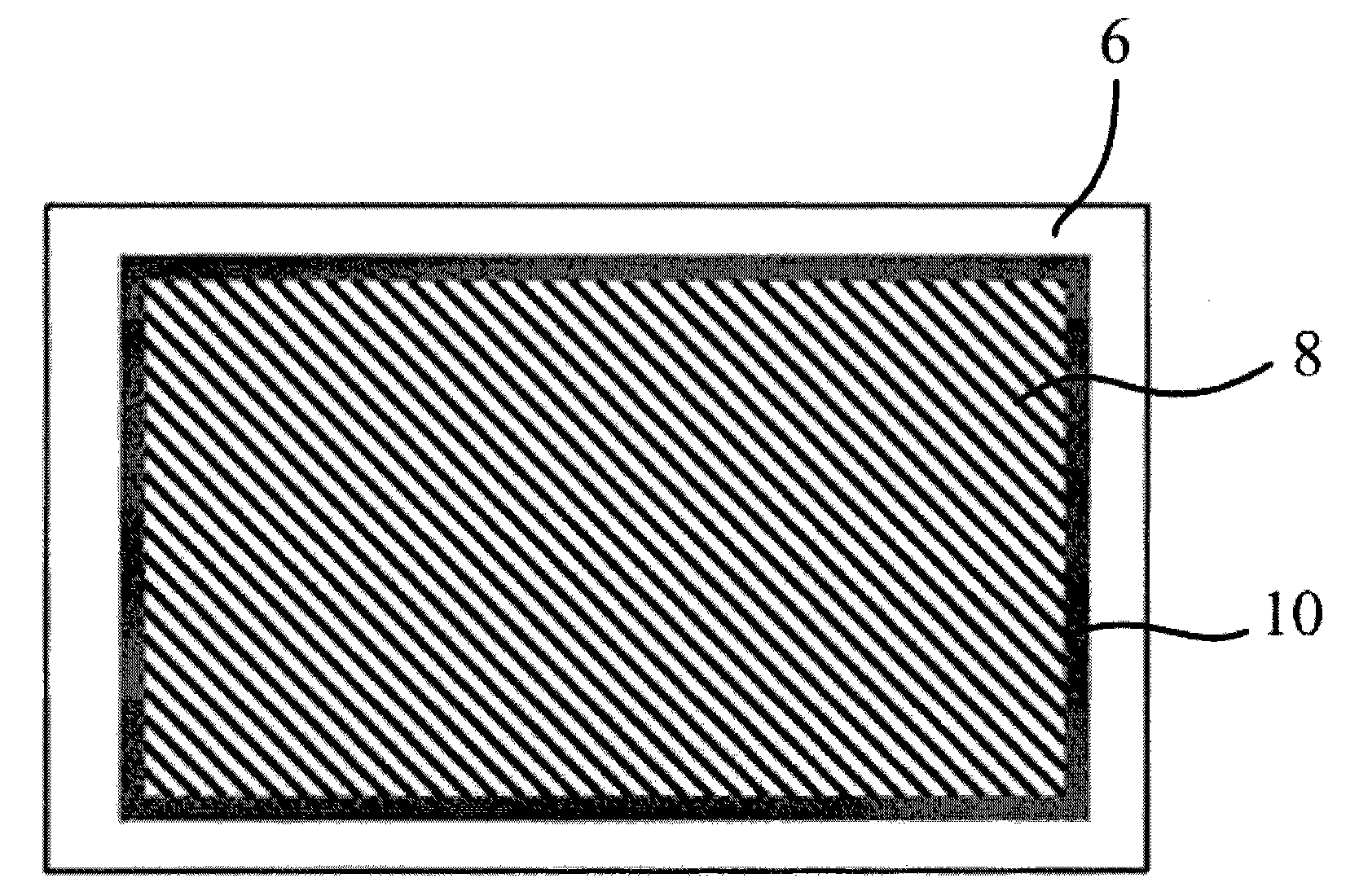

[0025] Specific embodiments of the present invention will now be described in detail, examples of which are illustrated in the accompanying drawings, wherein identical or similar reference numerals designate identical or similar elements. The present invention is described below by referring to the accompanying drawings, which are only for explaining the present invention, but not construed as limiting the present invention.

[0026] It should be noted that, in the description of the present invention, the terms "first", "second" and so on are only for the convenience of description of the present invention, and shall not be construed as limiting the present invention.

[0027] The main purpose of the present invention is to provide a single-sided FPC exposure method. Two layers of FPC are stacked, and the upper and lower light sources of the exposure machine are used to expose at the same time. Precise alignment reduces misalignment.

[0028] The exposure method of the singl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com