Exposure method and system

An exposure method and technology of an exposure system, which are applied in the field of exposure of exposure machines, can solve the problems of reducing exposure capacity of exposure machines and high exposure requirements, and achieve the effects of increasing exposure capacity, improving curing degree and increasing adhesion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The technical solutions of the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings of the present invention.

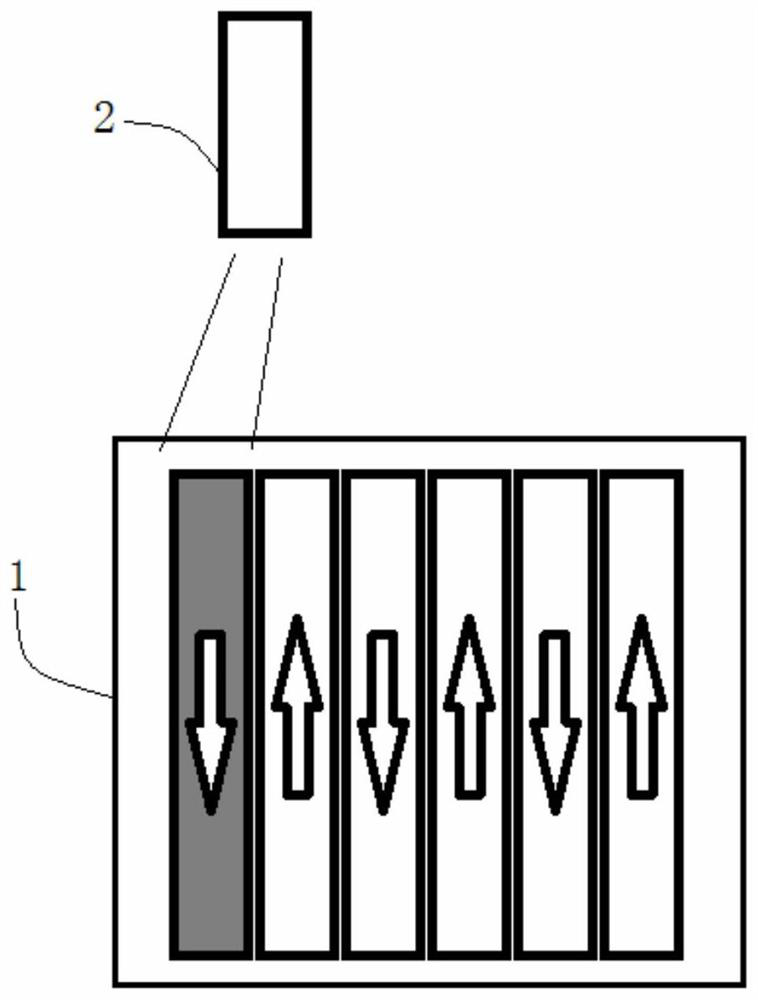

[0032] In the exposure method and system disclosed in the present invention, a secondary exposure process is added after the development step to expose and strengthen the film on the substrate, thereby increasing the exposure capacity of the exposure machine.

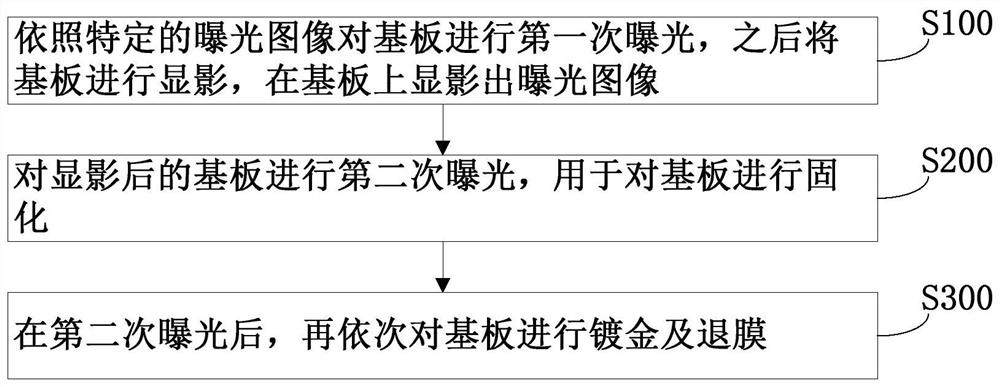

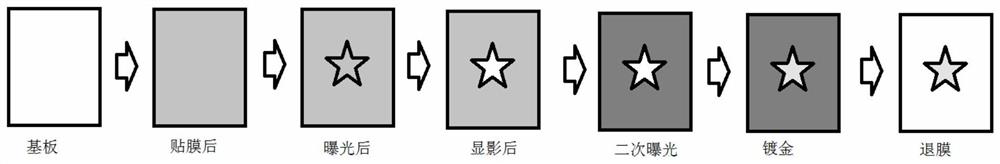

[0033] to combine figure 1 and figure 2 As shown, an exposure method disclosed in the present invention includes the following steps:

[0034] S100, exposing the substrate for the first time according to a specific exposure image, and then developing the substrate to develop the exposure image on the substrate.

[0035] Specifically, such as figure 2 As shown, the substrate here is a substrate with a dry film attached, that is, before the first exposure, a dry film is pasted on the surface of the substrate, and the dry fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com