Mass production type double-sided laser direct writing photoetching machine and control method thereof

A technology of laser direct writing and lithography, which is applied in the field of exposure machines, can solve the problems of low alignment accuracy and low efficiency of integrated circuit exposure, and achieves the advantages of avoiding low alignment accuracy, improving exposure efficiency, and improving exposure alignment accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Embodiments of the present invention are described in detail below, and the embodiments described with reference to the drawings are exemplary, and embodiments of the present invention are described in detail below.

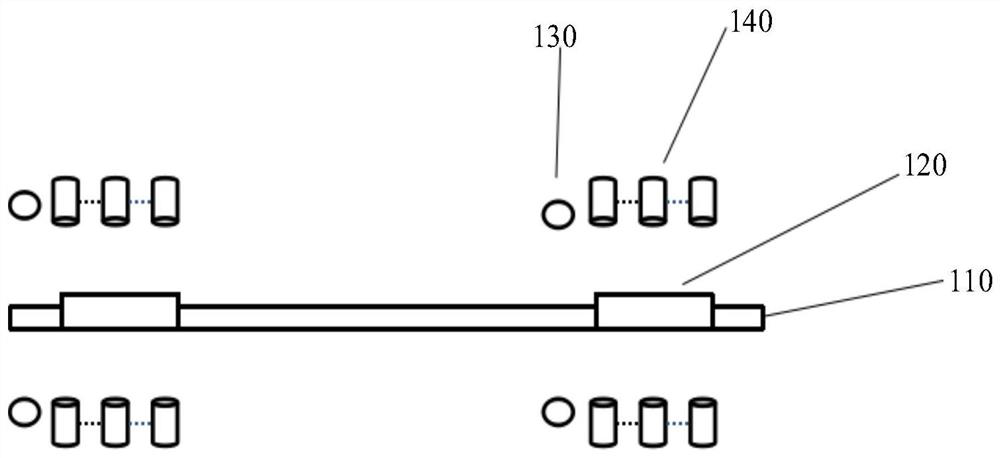

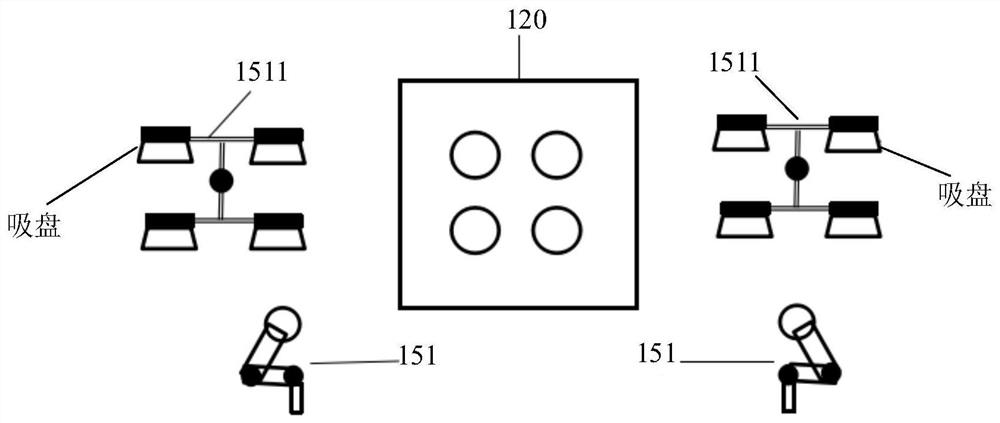

[0029] Refer below Figure 1-Figure 4 A mass-production double-sided laser direct writing lithography machine and a control method thereof according to an embodiment of the present invention are described.

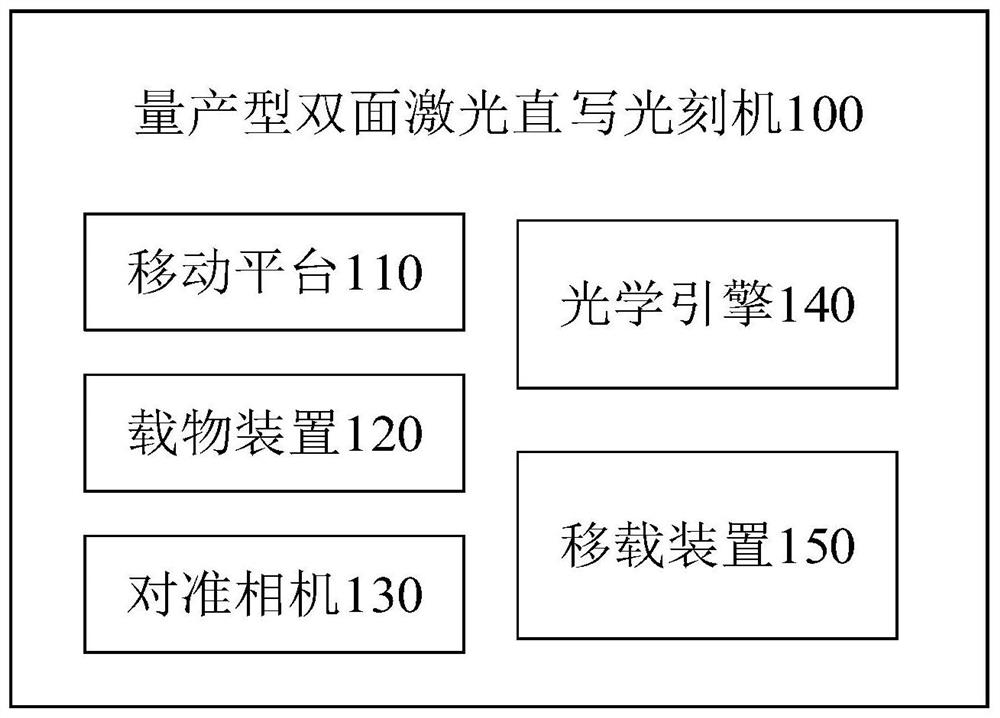

[0030] figure 1 It is a structural block diagram of a mass-production double-sided laser direct writing lithography machine according to an embodiment of the present invention. This mass-produced double-sided laser direct writing lithography machine can be applied to the manufacture of integrated circuits. It can expose both sides of multiple wafers in multiple regions at the same time, which solves the problems of low alignment accuracy and low efficiency of integrated circuit exposure. , which greatly improves the exposure production capacity, whic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com