Method for improving partition alignment efficiency of digital laser direct writing exposure machine

A laser direct writing and exposure machine technology, which is applied in microlithography exposure equipment, optomechanical equipment, photolithographic process exposure devices, etc. effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In the drawings, the same or similar reference numerals are used to denote the same or similar elements or elements having the same or similar functions. Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

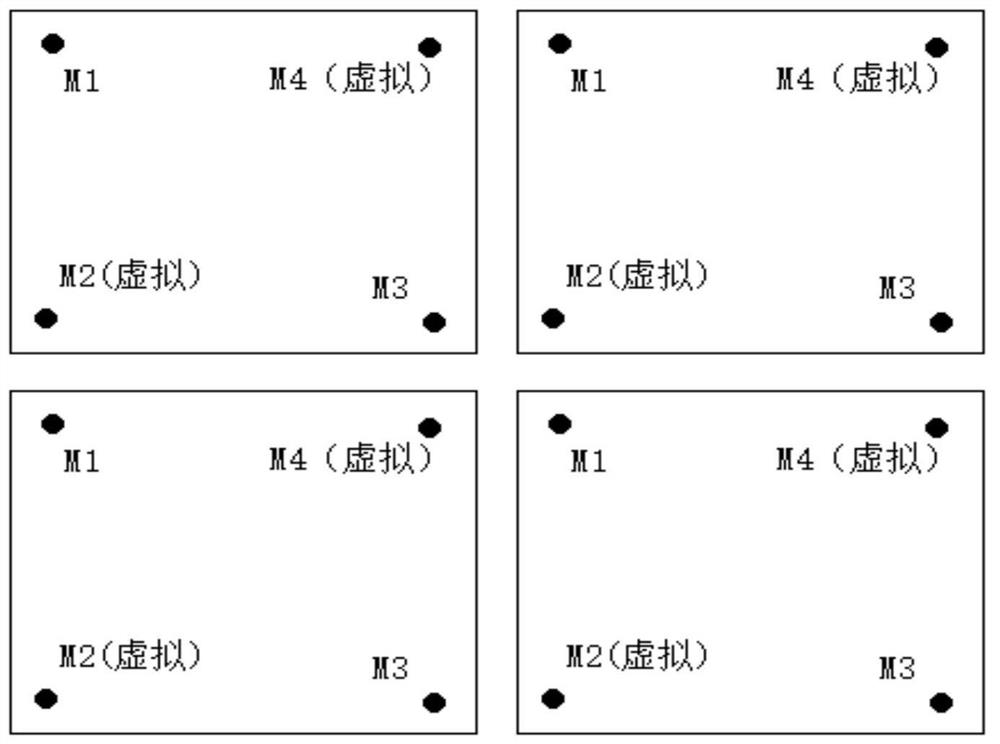

[0026] Aiming at the problem that it takes too long to grab a mark point for partition alignment, the present invention proposes a method for reducing the time for grabbing a mark point. When capturing mark points, each individual area only needs to capture two mark points at opposite corners, and the remaining two points are virtualized based on the captured mark points, and half of the mark points are captured. Since the method of virtualizing the mark point is not complicated, the time for virtualizing the mark point can be ignored with the computing speed of the current general office computer. Therefore, this method can reduce the time for capturing mark points by half, and significantly improve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com