New technology for oil sludge processing

A new process, sludge technology, applied in sludge treatment, water/sludge/sewage treatment, dehydration/drying/concentrated sludge treatment, etc., can solve the problems of wasting resources, low recovery rate, and reducing the quality of ash powder, etc. Achieve the effect of large input-output benefit, high oil recovery rate, and restoration of due quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The inventor obtains through investigation to conventional processing method and existing defect, and some is known from literature, and some is summed up through personal test, such as lubricating oil, paraffin, vegetable oil produced in refining process For oil sludge, the experiment was carried out with reference to the solvent extraction method of vegetable oil cake treatment. Through the above means, many conventional treatment methods for oil sludge were summarized and found, and their defects were deeply discovered.

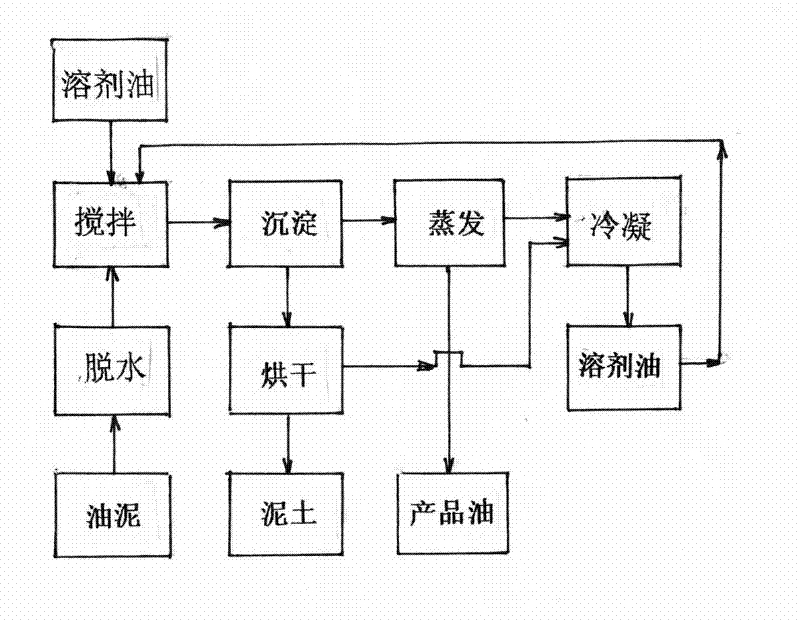

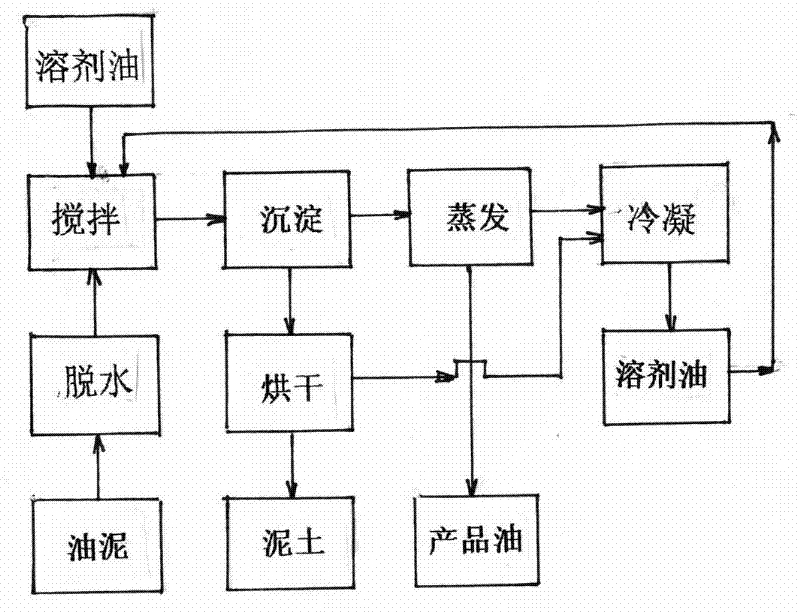

[0025] The design scheme of the present invention, referring to the accompanying drawings, was independently developed by the inventor through self-selected investment, and after trial operation, the pilot test was successively carried out on the oil sludge of lubricating oil, paraffin, and vegetable oil, and the effect was ideal. Miscellaneous, comparable to refined oil, the recovery rate is as high as 99%, the residual oil in the soil is less than ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com