Fibre grey cloth, manufacturing method and fibre grey cloth with lapping cloth forming by bonding lapping cloth on the fibre grey cloth

A fiber and grey fabric technology, applied in fiber processing, plant fibers, textiles and papermaking, etc., can solve problems such as no proposed and no effective methods, and achieve the effects of good shrinkage resistance, easy dirt falling off and less oozing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

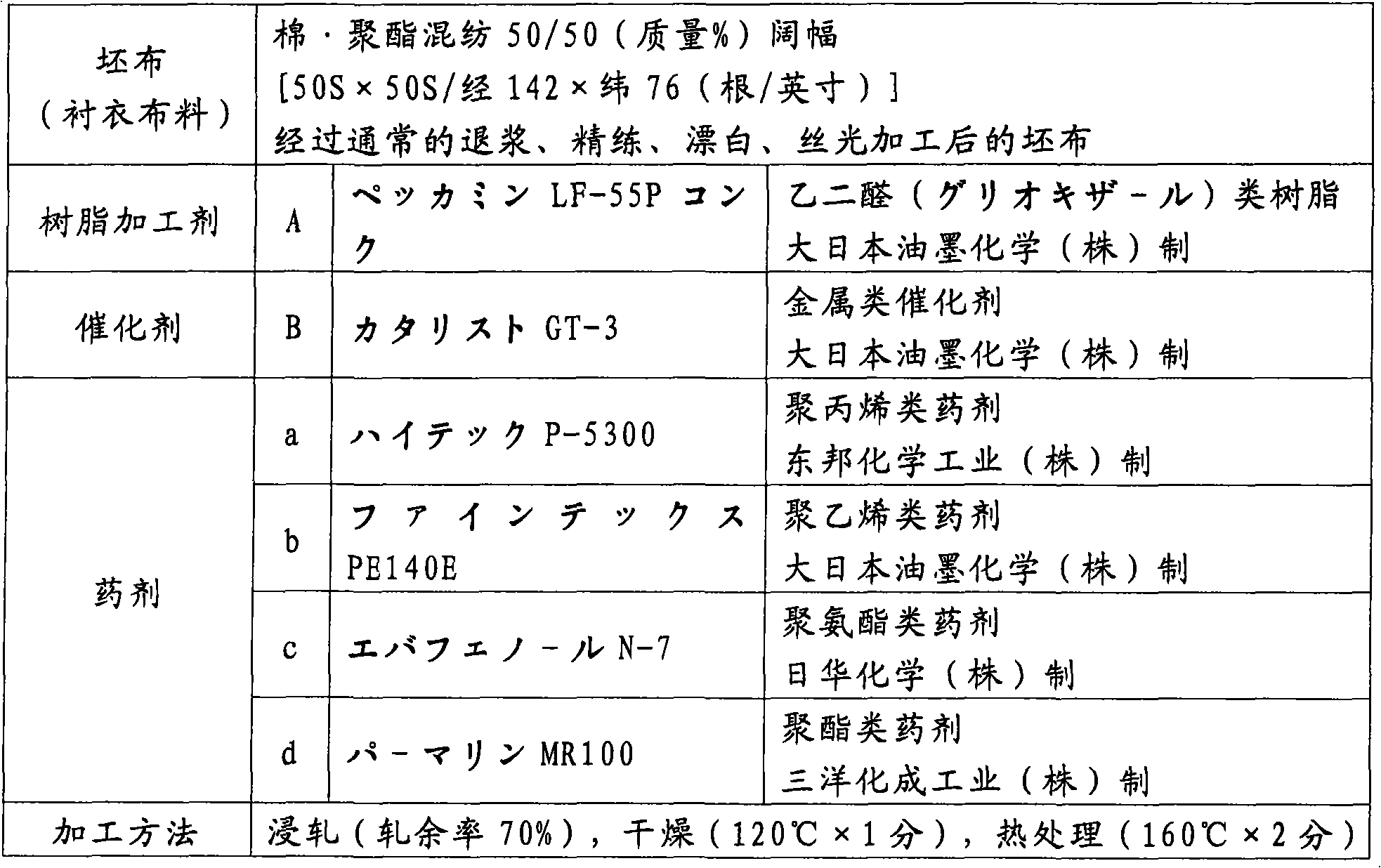

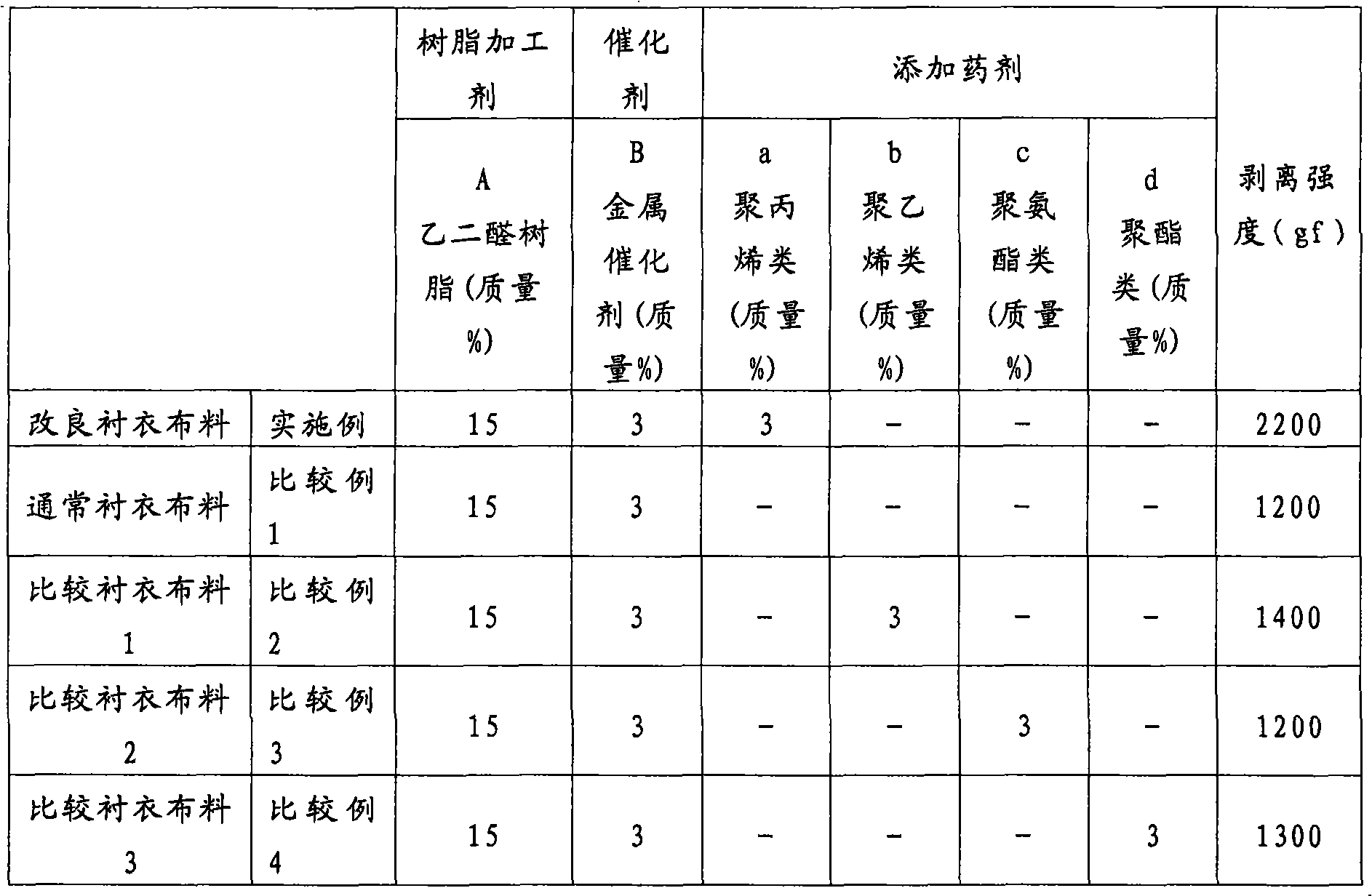

[0047] The shirt fabrics in Table 1 (gray fabrics after normal desizing, scouring, bleaching, and mercerizing) are used in resin processing agent A (ペツカミン LF-55Pコンク, manufactured by Dai Nippon Ink Chemical Co., Ltd., glyoxal (グリオキザ-ル) resin) 15% by mass, Catalyst B (Katarist GT-3, manufactured by Dainippon Ink Chemical Co., Ltd., metal catalyst) 3% by mass of conventional resin formulation solution with 3% by mass of polypropylene agent added a (Hitec P-5300, manufactured by Toho Chemical Co., Ltd.) to form a treatment solution (aqueous solution), padding (rolling over rate 70%), drying (120°C x 1 minute), and heat treatment (160°C) ×2 points) to get an improved shirt fabric.

[0048] It should be noted that the rolling margin ratio is calculated by the following formula.

[0049] Rollover ratio=[(weight of target after treatment)-(weight of target before treatment)] / (weight of target before treatment)×100

[0050] Table 1

[0051]

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com